Fire coal gas heating furnace nozzle ignition device and application method

An ignition device and heating furnace technology, applied in the direction of combustion ignition, combustion method, lighting and heating equipment, etc., can solve the problems of high operation failure rate, high configuration of heating furnace burner ignition system, etc., and achieve low investment cost and simple maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] Example 1

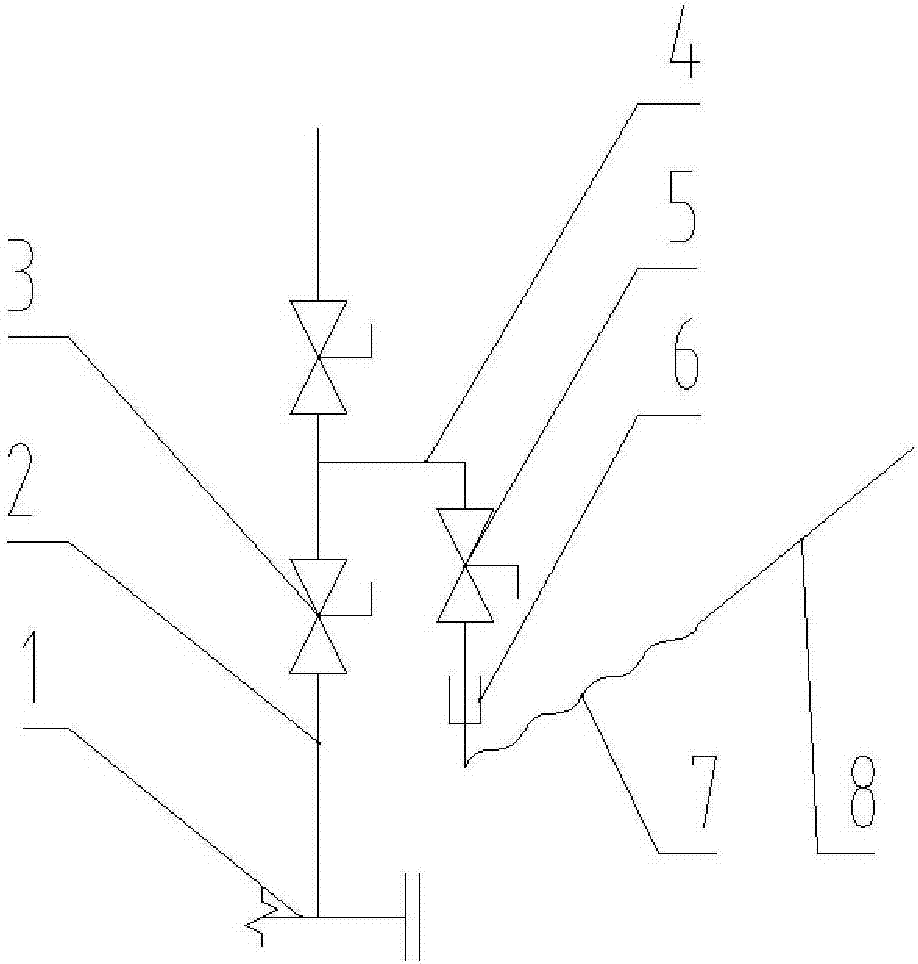

[0015] A new type of burner ignition device for a gas-fired heating furnace and its use method, which mainly consists of a gas supply main pipe 1 in front of the burner nozzle, a discharge pipe 2, a discharge stop valve 3, a sampling pipe 4, a sampling stop valve 5, and a pipe cap 6 , Rubber hose 7, ignition tube 8 form. When the heating furnace is turned on and ignited, the gas system should be purged and released first, and the release stop valve 3 should be opened. After 20-30 minutes of release through the release pipe 2, the sampling stop valve 4 and the pipe cap 6 should be opened to carry out the "explosion" test. Detect the amount of residual oxygen in the gas pipeline. After passing the test, connect the rubber hose 7 and the ignition tube 8 at the end of the sampling tube 5, put a lighter on the end of the ignition tube 8, open the sampling shut-off valve 4, and press the lighter switch. Form a stable flame at the end of the ignition tube 8, loose...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap