Material contract performance information control method

A material and contract technology, applied in logistics, instruments, data processing applications, etc., can solve the problems of real-time information lag, untimely information, and suppliers unable to contact receiving personnel, and achieve the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

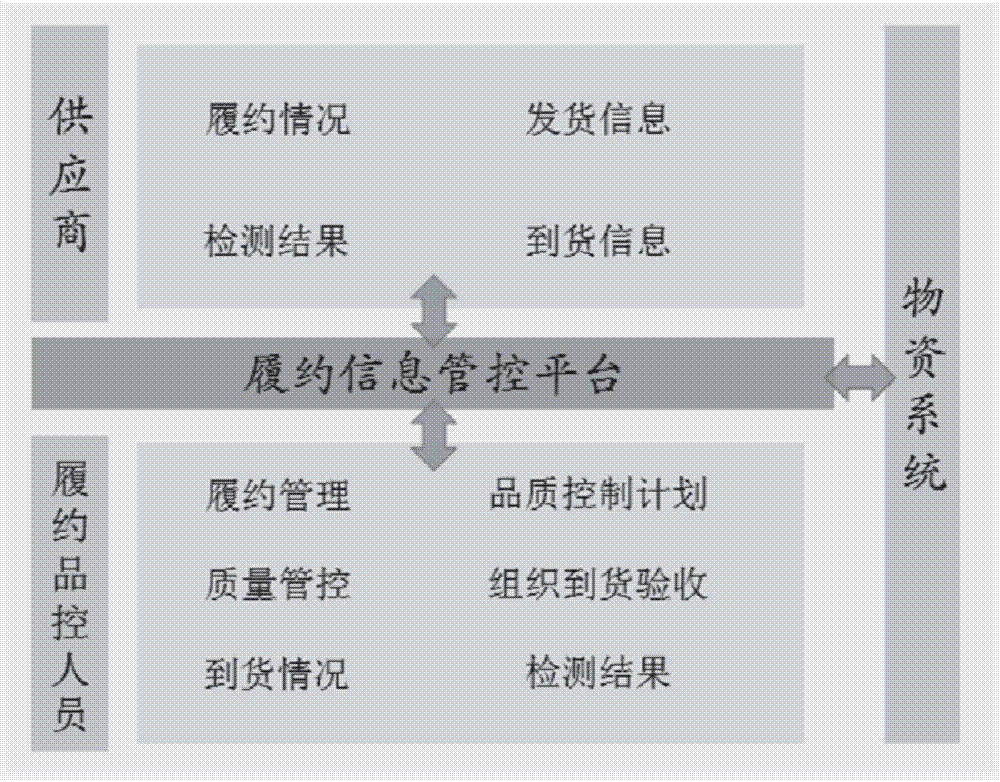

[0052] Such as figure 1 As shown, a power material contract performance information control method includes the following steps:

[0053] S1: Establish a contract performance information management and control platform, the contract performance information management and control platform includes one or more cloud servers;

[0054] S2: When the supplier's delivery and receiving personnel receive the goods, the delivery and receipt information is entered into the performance information management and control platform through the instant messaging device, so as to realize the real-time update of the material delivery and arrival information in the performance information management and control platform; instant messaging Devices include but are not limited to mobile terminals such as mobile phones, PDAs or tablet computers.

[0055] S3: After the user enters the information in the contract performance information management and control platform, the contract performance inform...

Embodiment 2

[0059] On the basis of Embodiment 1, this embodiment further completes the random inspection of materials, which specifically includes the following steps:

[0060] T1: The contract performance quality control personnel of the logistics service center prepare the monthly sampling inspection pre-plan on the contract performance information management and control platform;

[0061]T2: The performance quality control personnel of the power supply bureau confirm whether it is included in the scope of monthly sampling inspection in the contract performance information management and control platform;

[0062] T3: The logistics service center sends the confirmed pre-sampling plan to the material department of the company;

[0063] T4: The material department organizes a monthly sampling inspection plan approval meeting;

[0064] T5: The logistics service center adjusts the monthly sampling inspection pre-plan according to the requirements of the monthly sampling inspection plan rev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap