High-flatness load-bearing ground rail

A flatness and ground rail technology, which is applied in the field of rail vehicle strength test foundation platform, can solve problems such as load-bearing ground rail deformation, load-bearing ground rail meets flatness, etc., to ensure reliability, ensure loading accuracy, and reduce manual labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

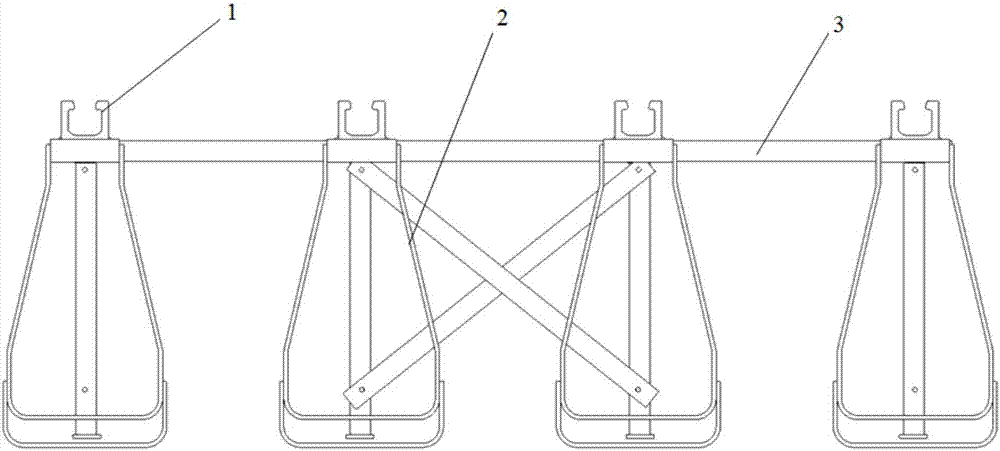

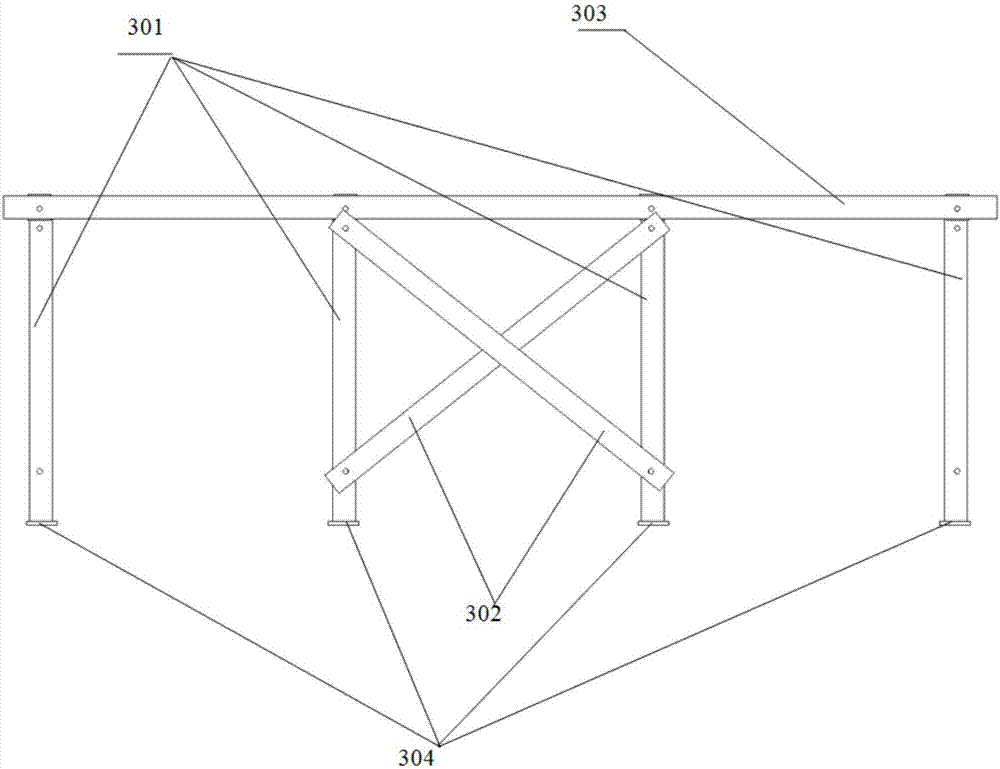

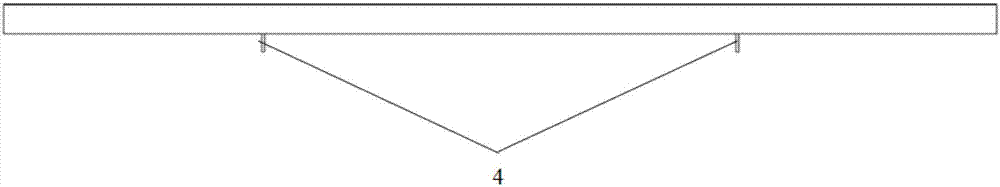

[0013] Reference figure 1 with figure 2 , The present invention includes a number of rails 1, ground anchor assembly 2, a number of load-bearing supports 3 are connected below the track, each load-bearing support is composed of a cross beam 303, a number of vertical beams 301 and two diagonal beams 302, the vertical beams correspond to Set at the track, the adjusting screw 304 is connected under the vertical beam, the track is clamped between the cross beam and the vertical beam and fixed, the two diagonally-stayed beams are cross-connected with the two vertical beams in the middle through the long round hole, and only the track is restricted during the connection process The vertical freedom of the track can be adjusted manually in the horizontal direction, so that the horizontal and vertical position of the track can be adjusted. One end of the adjusting screw is fixed in the concrete, and the other end is connected with the vertical beam. The position of each point of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com