An adjustable conveying flat device

A flat plate and support rod technology, applied in the direction of printing device, printing, etc., can solve the problems of deviation of the guide belt, affecting the printing quality, heavy equipment, etc., and achieve the effect of adjustable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

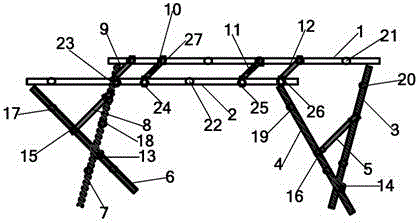

[0010] Depend on figure 1 As shown, an adjustable conveying flat device includes a left support frame and a right support frame, wherein the left support frame includes the first left support rod 6 and the second left support rod 7, and the first left support rod 6 and the second left support rod 7 intersect Type connection, the first left screw hole 17 arranged at continuous intervals is arranged on the first left support rod 6, the second left screw hole 18 arranged at continuous intervals is arranged on the second left support rod 7, the first left support rod 6 and the second left support The rod 7 is embedded in the first left screw hole 17 and the second left screw hole 18 through the left rivet 13 at the intersection to realize the rotatable connection between the two. A left connection is connected between the first left support rod 6 and the second left support rod 7. Crossbar 8, left connecting crossbar 8 is arranged at continuous intervals with left connecting embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com