A poultry feed delivery mechanism

A feeding mechanism and feed technology, applied in poultry industry, application, animal husbandry, etc., can solve the problem of high labor intensity of workers, and achieve the effect of reducing labor intensity, easy to use, and avoiding back and forth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

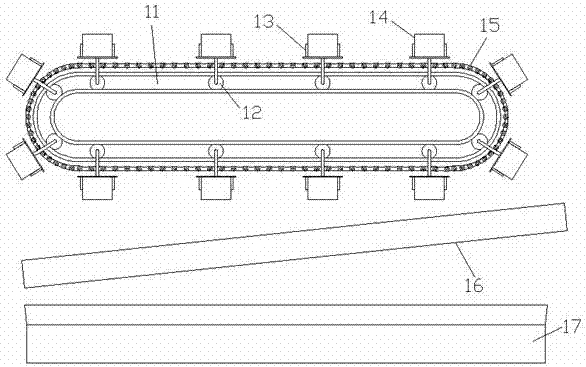

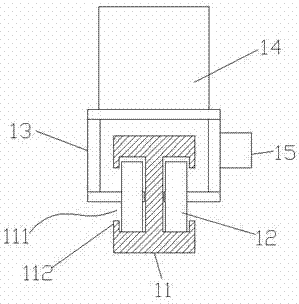

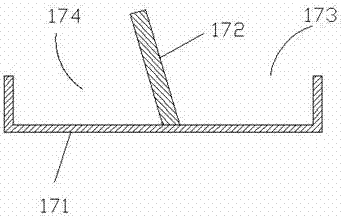

[0017] Such as Figure 1 to Figure 3 As shown, the feed mechanism of a kind of poultry feed of the present invention comprises annular track 11, roller 12, connection seat 13, feed box 14, transmission chain 15, transmission sprocket wheel, material guide trough 16 and feed chute 17, connection seat 13 One end of one end is connected with the roller 12, and the roller 12 is rotatably connected on the circular track 11, the feed box 14 is fixed on the connection seat 13, the transmission chain 15 is arranged on one side of the circular track 11, and the transmission chain 15 is meshed with the transmission sprocket, The connecting seat 13 is fixedly connected with one end face of the transmission chain 15, the material guide groove 16 is arranged obliquely below the annular track 11, and several through holes are arranged in the material guide groove 16, and the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com