Sheet laser back reflection synergism welding method for regulating back face energy field with auxiliary electric field

A welding method and auxiliary electric field technology, applied in laser welding equipment, welding equipment, metal processing and other directions, can solve the problems of high dispersion and poor directionality of the metal vapor cloud on the back, and achieve improved protection, efficiency, and good adaptation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

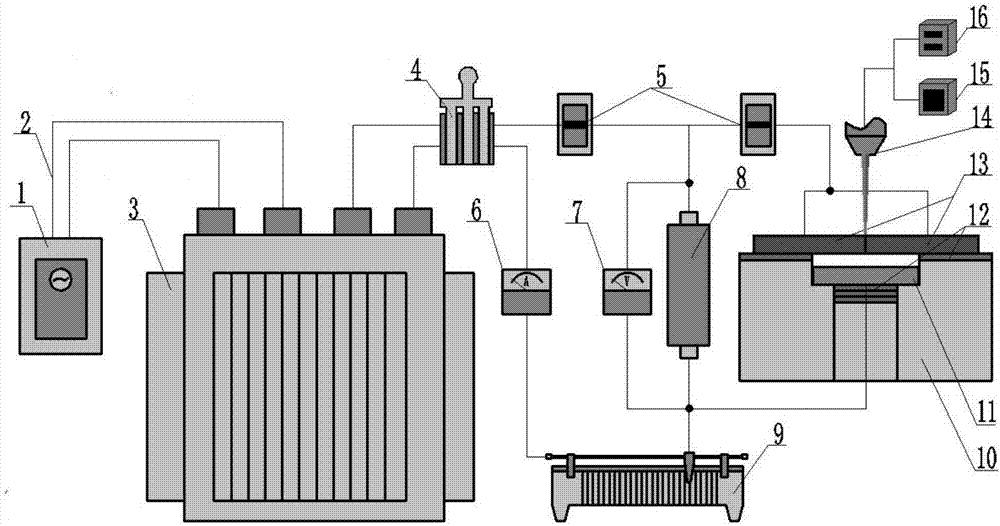

[0032] Such as Figure 1-5 shown.

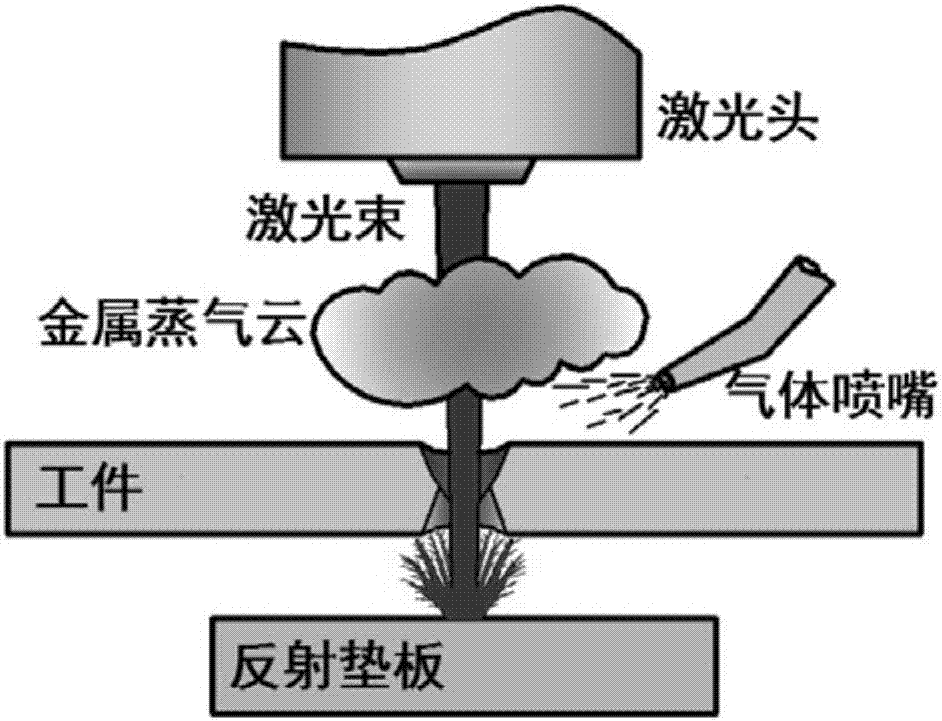

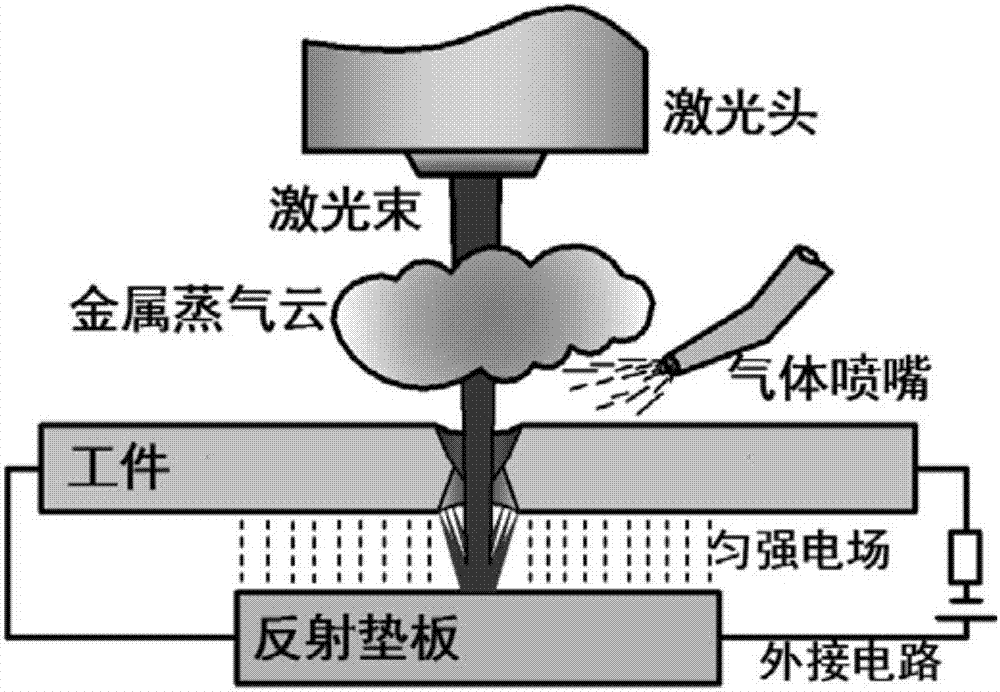

[0033] A thin-plate laser back reflection synergistic welding method with an auxiliary electric field to regulate the energy field on the back. The essence and key is to construct a parallel plate capacitor by introducing direct current between the welding thin plate and the reflective backing plate on the back, and use the parallel plate capacitor to generate a uniform electric field. The characteristics of the metal vapor cloud on the back of the weldment are regulated and regulated to ensure that the direction and concentration of the metal vapor cloud induced by the reflective backing plate are better when they return to the back welding area.

[0034] The specific steps are:

[0035] A) First convert the 220V AC to DC through a transformer rectifier;

[0036] B) After connecting the output terminal of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com