A kind of production method of diaminodiphenyl ether

A technology of diaminodiphenyl ether and its production method, which is applied in the fields of chemical instruments and methods, the preparation of amino hydroxyl compounds, and the preparation of organic compounds, etc., and can solve the requirements of heavy water treatment burden, long process heating and constant temperature time, and sublimation process technical conditions High-level problems, to achieve the effect of less residual salt impurities and sewage, simple cleaning and post-treatment, and low risk of safety and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

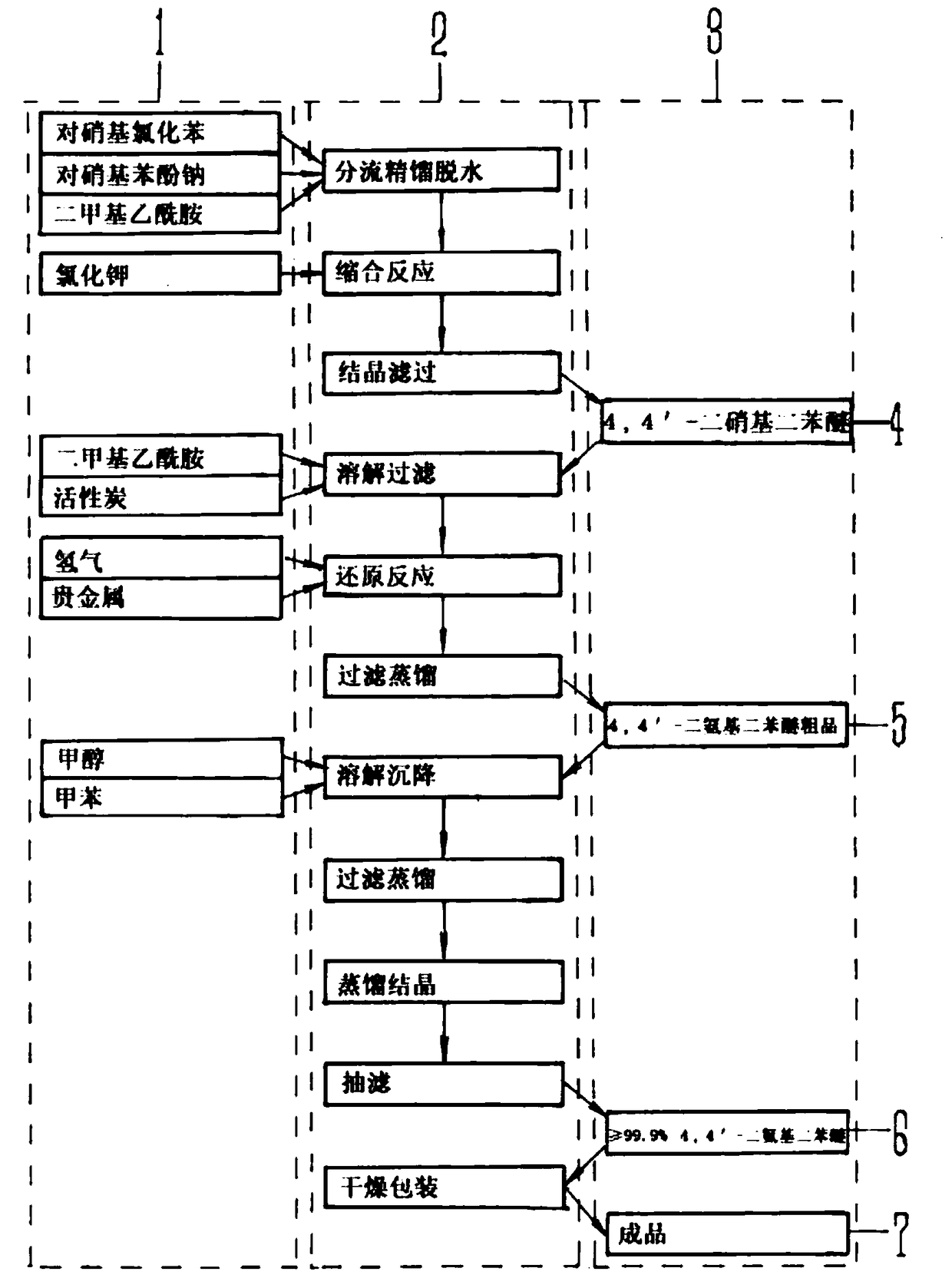

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail as follows:

[0024] The high-efficiency, energy-saving and environmentally friendly new diaminodiphenyl ether production line of the present invention was developed and implemented during the "10000T / year recrystallization method production of high-purity diaminodiphenyl ether project" by Guansen Insulation Products Co., Ltd., Dongying City, Shandong Province.

[0025] like figure 1 Shown: A new type of diaminodiphenyl ether production line with high efficiency, energy saving and environmental protection to produce 4,4'-dinitrodiphenyl ether 4, 4,4'-diaminodiphenyl ether crude product 5, purity ≥ 99.9%4 , 4'-diaminodiphenyl ether 6 and product 7 are divided into four stages: condensation reaction, reduction reaction, refining and purification, and dry packaging. The main input material 1, process 2 and product 3 are summarized into three parts.

[0026] In the process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com