Automatic knotting mechanism

An automatic knotting and rotating mechanism technology, which is applied in the field of knotting machines, can solve the problems of increasing enterprise costs, high labor intensity, and inability to overcome the limitations of manual knotting, so as to reduce labor intensity, reduce enterprise costs, and improve knotting efficiency effect with mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

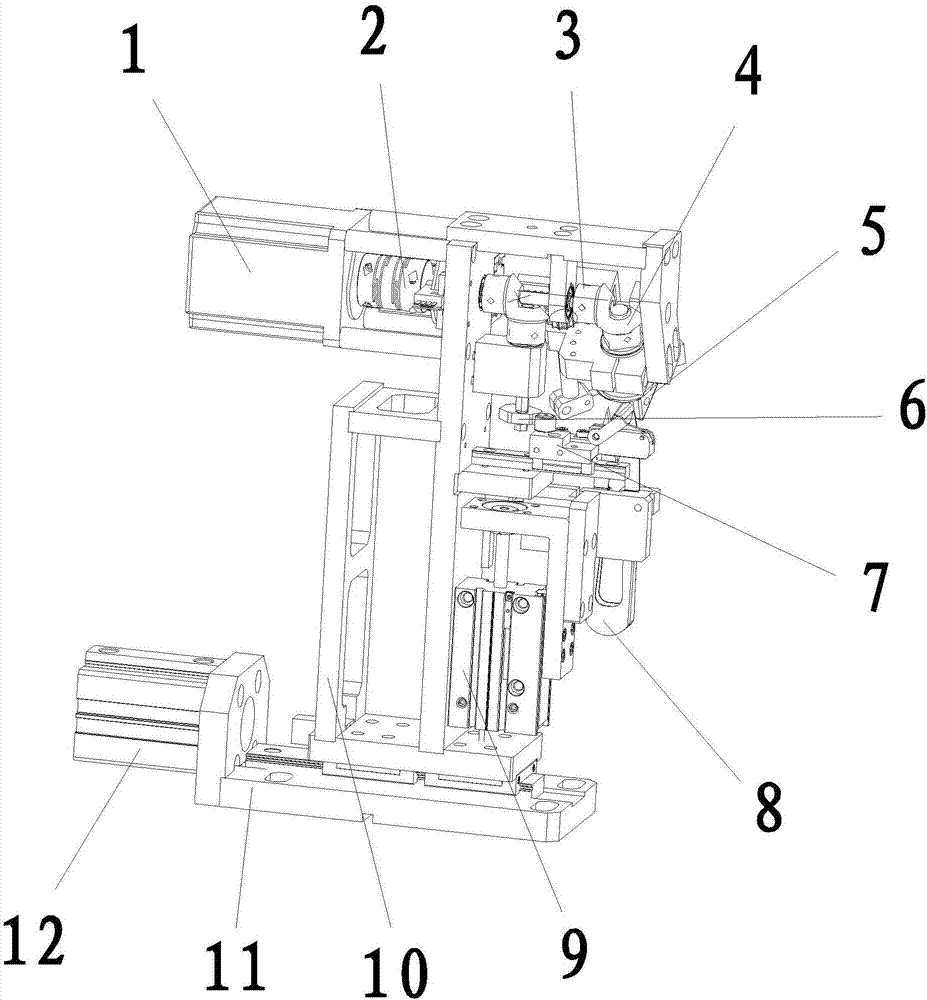

[0018] see figure 1 , the present invention provides an automatic knotting mechanism: its structure includes a servo motor 1, a rotating mechanism 2, a helical gear 3, a cam 4, a beak 5, a cam mechanism 6, a slider 7, scissors 8, a cutting cylinder 9, a fixed The plate frame 10, the positioning horizontal plate 11, and the propulsion cylinder 12, the right side of the propulsion cylinder 12 is installed on the left side of the positioning horizontal plate 11, the described rotating mechanism 2 is connected to the inside of the servo motor 1, and the described rotating mechanism 2. The right side runs through the fixed frame 10 and is connected with the helical gear 3. The cam 4 is installed on the upper end of the right side of the fixed frame 10....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap