Comprehensive coordination system for conveniently adjusting rotating speed difference of paper pasting machine at any time

A technology of poor rotation speed and paper paste, applied in mechanical equipment, differential transmission, belt/chain/gear, etc., can solve the problems of product quality, speed error of subordinate equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

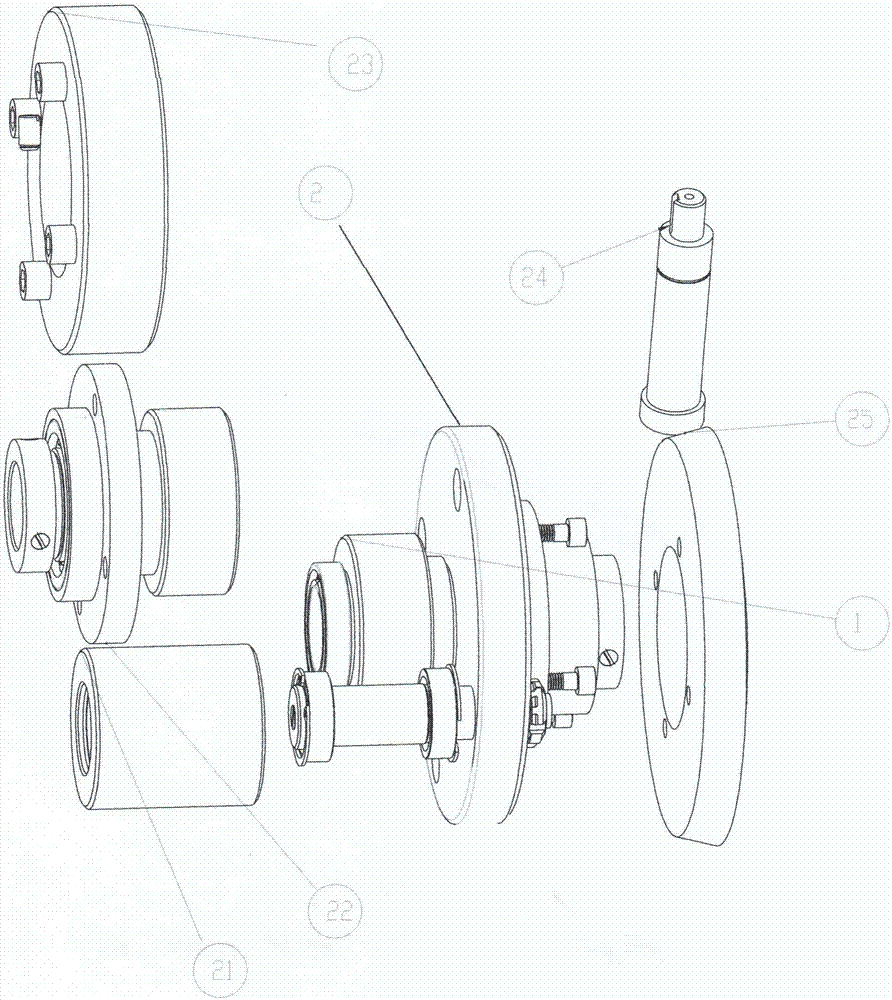

[0009] refer to figure 1 , the comprehensive coordination system provided by the present invention is convenient to adjust the rotation speed difference of the paper gluer at any time. The driving gear 1 is connected to the differential mechanism 2, and the differential mechanism 2 is connected to the slave equipment (not shown in the figure). The differential mechanism 2 Including driven gear 21, bull gear 22, slave equipment gear 23, trimming gear 24 and trimming gear 25, described driving gear 1 meshes with driven gear 21, driven gear 21 and bull gear 22 gears, bull gear 22 and slave The device gear 23 meshes, and the fine-tuning gear 24 and the fine-tuning gear 25 mesh.

[0010] When the transmission speed of the slave equipment (not shown in the figure) is inconsistent with other mechanisms and needs to be adjusted, turn the fine-tuning gear 24, and the fine-tuning gear 25 meshing with the fine-tuning gear 24 will move clockwise or counterclockwise accordingly, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com