An ion source etching device for realizing angle etching

A technology of etching equipment and ion source, which is applied to circuits, discharge tubes, electrical components, etc., can solve the problems of increasing the probability of ion source being polluted by particles, decreasing etching efficiency, and large distance gap, so as to solve the problem of etching Etch uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the present invention. But those skilled in the art should know that the following examples are not the sole limitation to the technical solution of the present invention, and any equivalent transformation or modification made under the spirit of the technical solution of the present invention should be considered as belonging to the protection of the present invention scope.

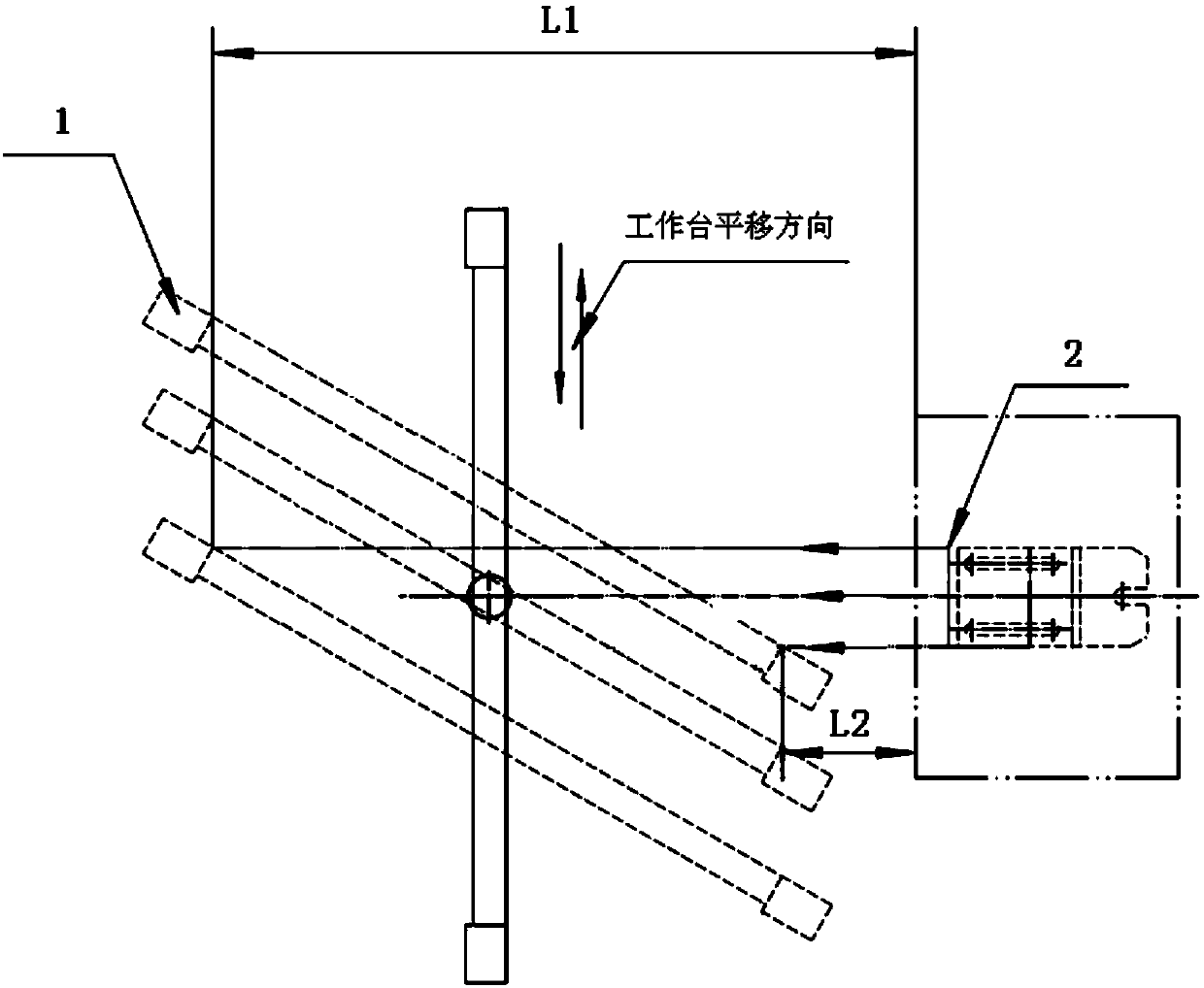

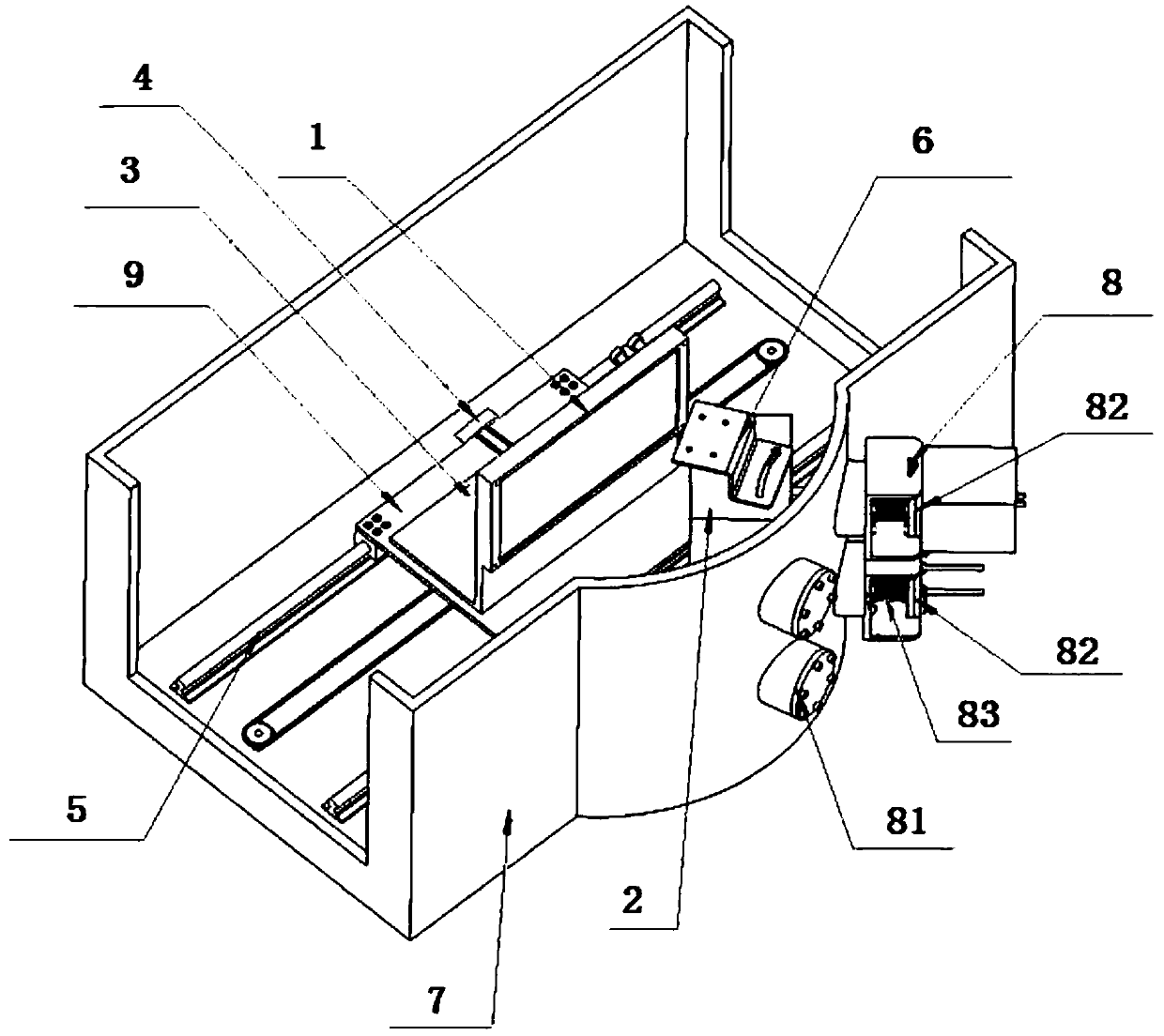

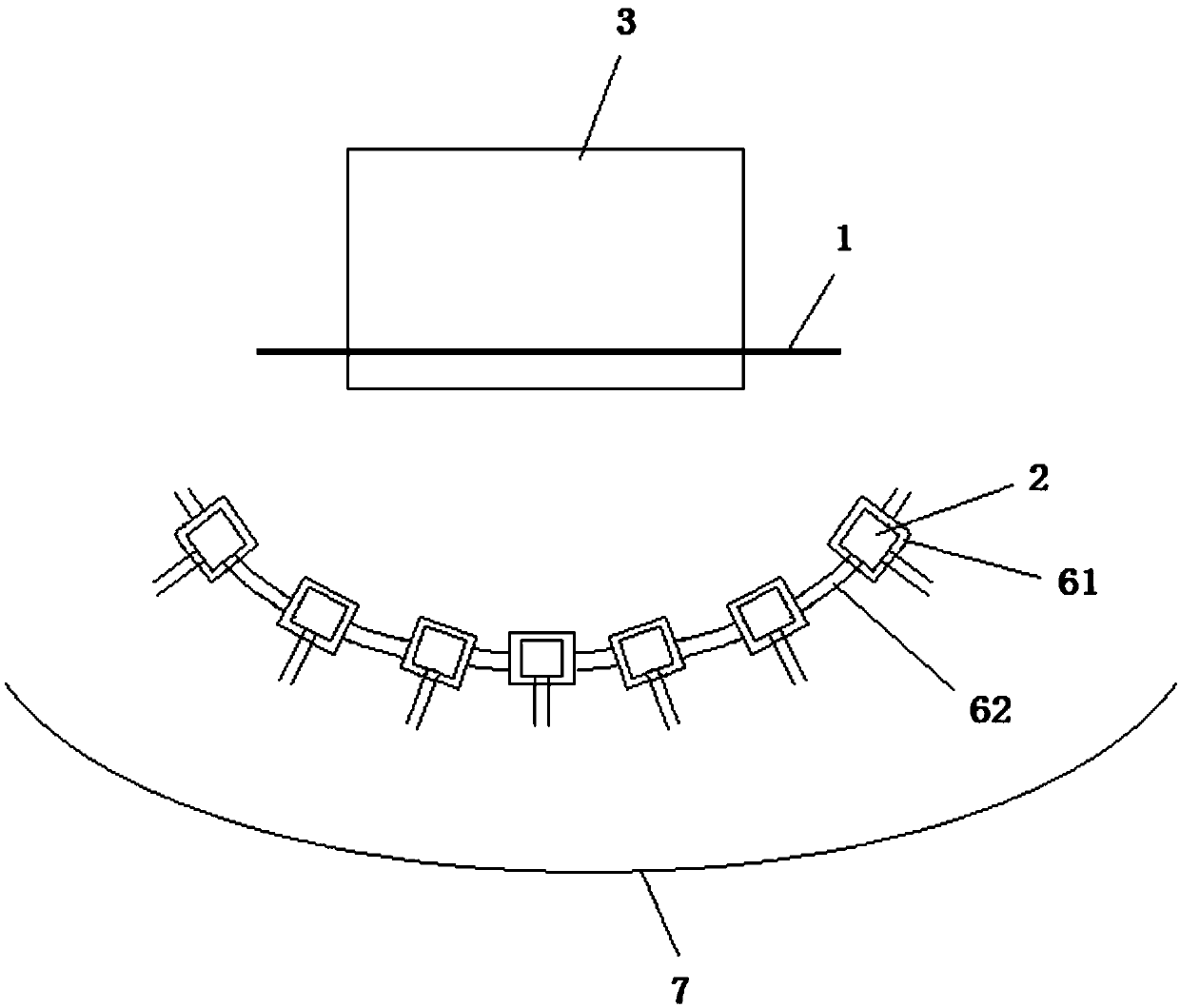

[0029] Such as figure 2 The illustrated embodiment is an ion source etching device for achieving angle etching, which mainly includes an ion source 2, a workpiece table 3, a first moving device 4, a second moving device 5, and a third moving device 6 , Vacuum chamber 7, Vacuum external connection device 8.

[0030] The workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com