Automatic lifting and lowering material frame with light source suitable for vision robots

An automatic lifting and robot technology, applied to containers, rigid containers, packaging, etc., can solve the problem of camera movement, etc., to achieve the effect of weakening the impact, quick response, and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

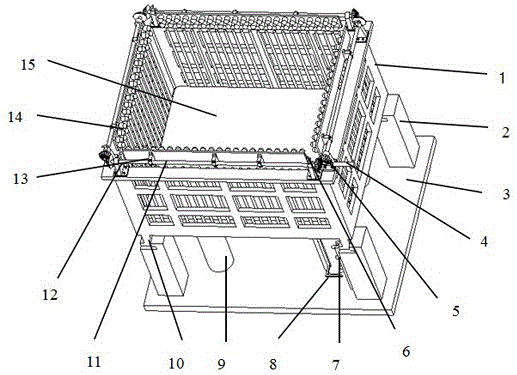

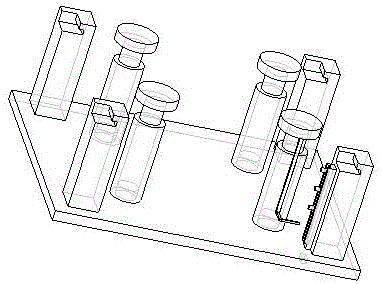

[0019] The present invention is suitable for a visual robot with a light source and can automatically lift the material frame, which includes a material frame main body 1, a material frame bottom plate 15, four sets of LED lights 14, an LED light angle adjustment tool 4, a conical gear 5, and LED light fastening screws 6, four Root LED lamp rotation shaft 11, LED lamp connection base 12, LED lamp and shaft connector 13, material frame base support column 2, material frame base fixed plate 3, travel switch 7, travel switch contact 8 and hydraulic cylinder 9.

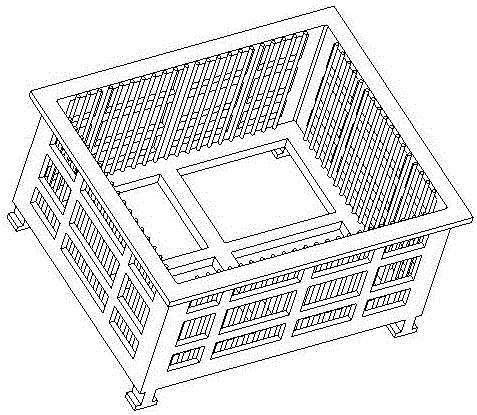

[0020] Such as figure 1 , figure 2 shown. The main body 1 of the material frame is welded by profiles, and the skeleton is composed of angle steel and rectangular steel, which mainly bears the gravity of the material and various external forces during the handling process. Several thin steel bars wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com