Change-over cabinet internal structure with copper-bar lap-joint control switch

A technology for controlling switches and internal structures, applied in substation/switch layout details, busbar/line layout, electrical components, etc. The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

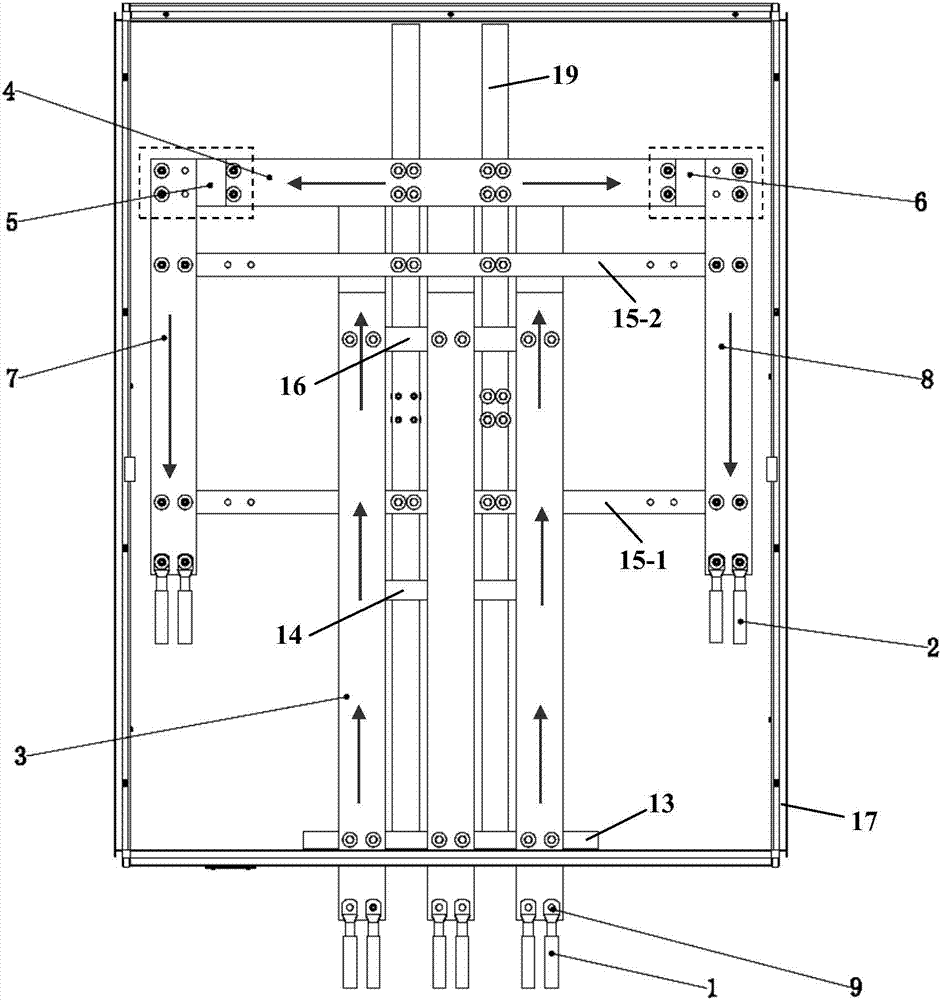

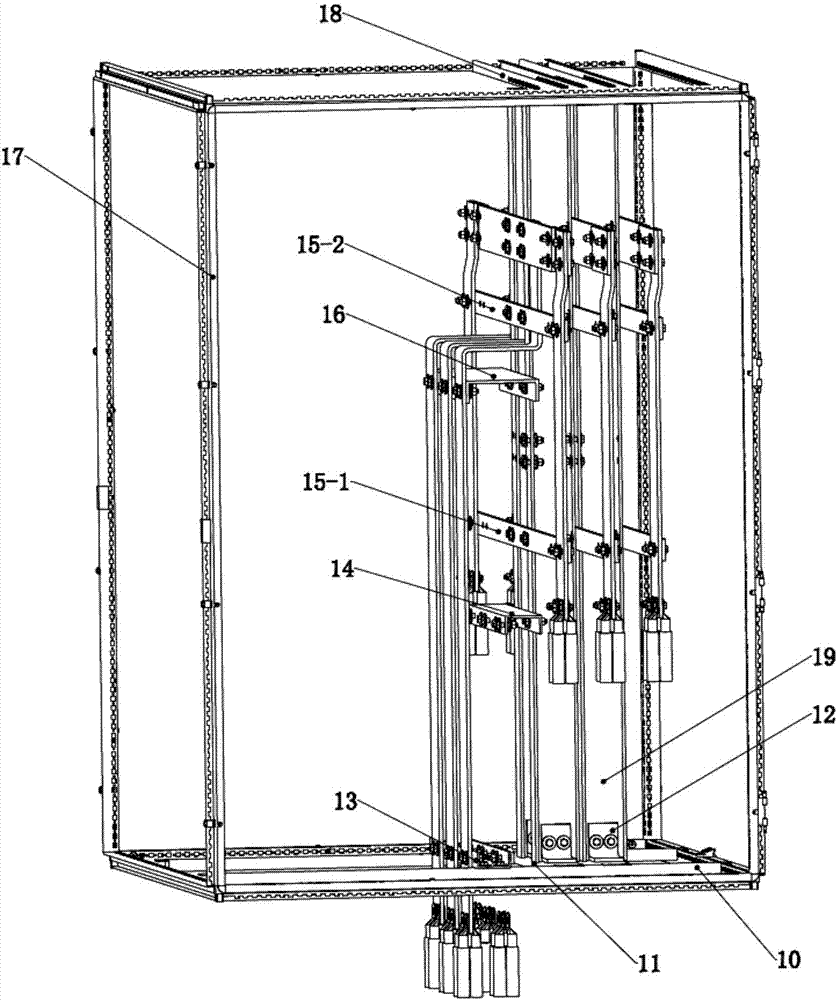

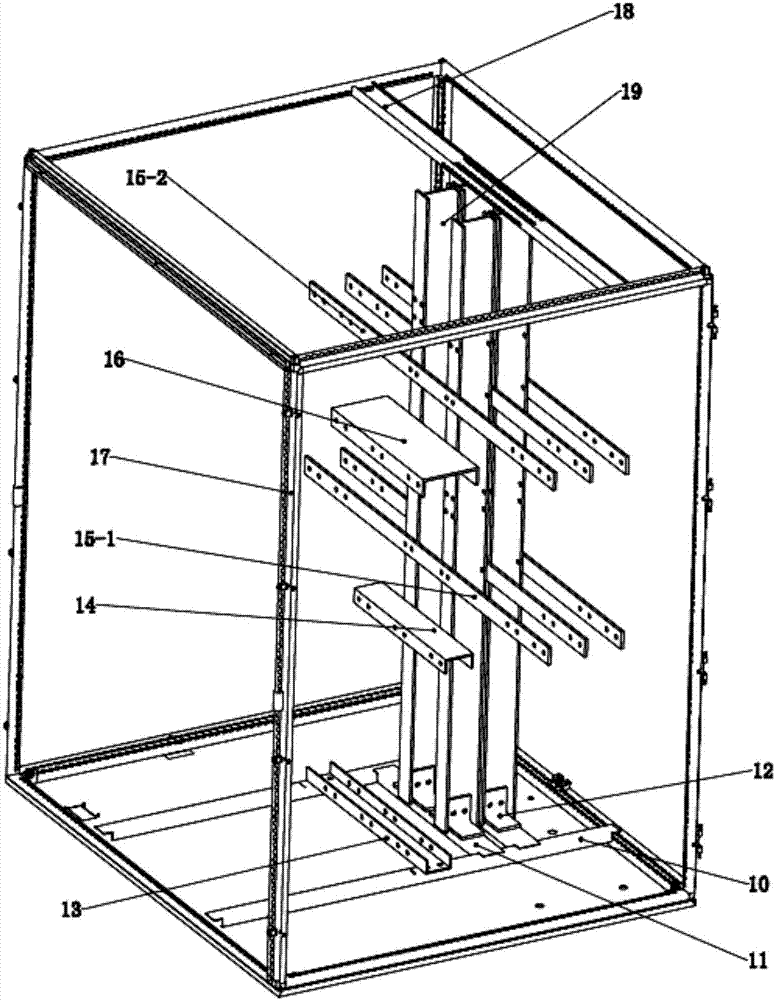

[0016] The internal structure of the transition cabinet of the copper bar overlapping control switch provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] Such as Figure 1-Figure 3 As shown, the internal structure of the transfer cabinet of the copper bar lap control switch provided by the present invention includes:

[0018] Convergence copper bar 3, shunt copper bar 4, first switch copper bar 5, second switch copper bar 6, first output side copper bar 7, second output side copper bar 8, C-shaped steel material 10, C-shaped base steel material 11 , Angle steel fixing frame 12, the first C-shaped insulating profile 13, the second C-shaped insulating profile 14, the first flat insulating fixing plate 15-1, the second flat insulating fixing plate 15-2, the third C-shaped insulating profile 16, Simple cabinet frame 17, C-shaped top steel 18, I-shaped steel insulating profile 19;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com