Elastic corner fitting for frames

An elastic angle and frame technology, applied in the field of door and window parts, can solve the problems of not meeting the requirements of the times, lack of modernity, poor visual effect, etc., to improve assembly efficiency, ensure dimensional accuracy, and facilitate processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

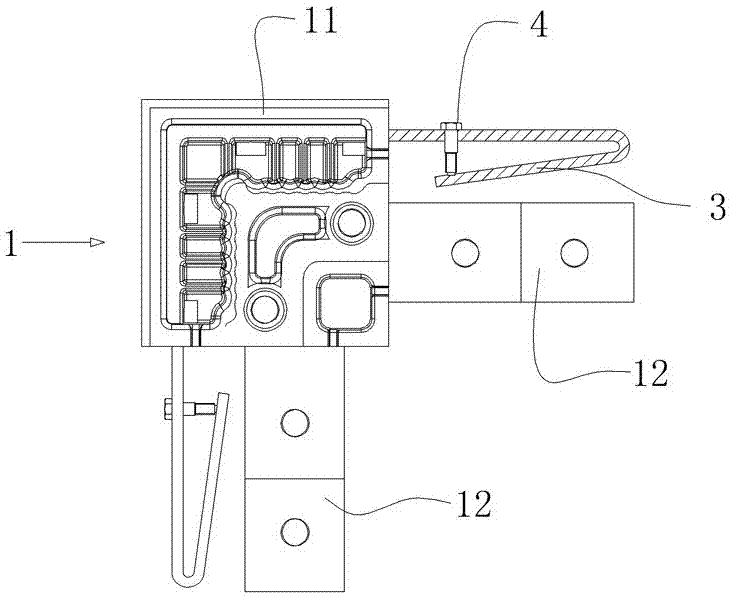

[0013] The frame of this embodiment uses elastic corner fittings, such as figure 1 and figure 2 As shown, the corner piece 1 is used for connecting the ends of two adjacent rectangular frames 2 .

[0014] The corner fitting 1 includes a block body 11 and at least two groups of splint groups 12. The block body 11 is formed with an end face abutting against the end of the adjacent frame 2. Each group of splint group 12 is formed by an end face fixed at one place of the block body 11. It consists of the upper elastic board and the left and right splints arranged in the shape of a character.

[0015] The block body 11 is a rubber block body, the upper elastic plate and the left and right splints are metal splints, and the corner piece 1 is formed by die-casting the rubber block body and the metal splint. Threaded holes are formed on the left and right splints.

[0016] The left and right splints are respectively tightly clamped on two opposite sides of the frame 2, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com