AGV quantity configuration method based on real-time scheduling simulation and queuing theory

A technology of real-time scheduling and configuration method, applied in the field of resource allocation in workshops and warehousing logistics, can solve the problems of less research, long calculation and statistical process, and low level of precision, so as to reduce costs, scientific decision-making costs, and simplify calculation and statistical processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

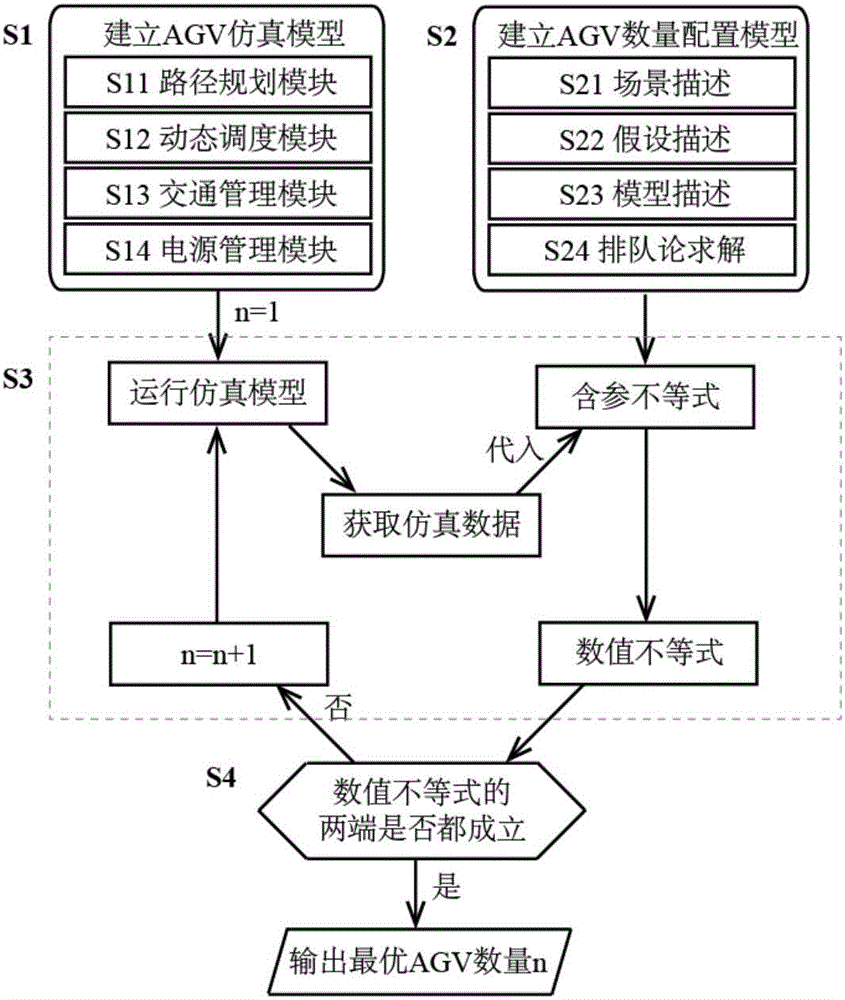

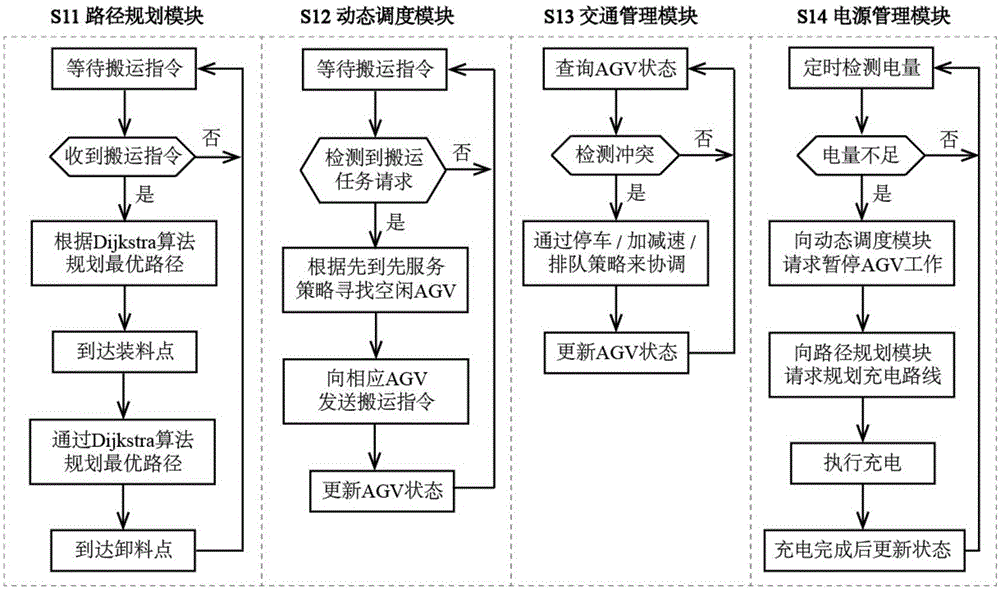

[0039] combine figure 1 with figure 2 Describe this specific implementation mode, a kind of AGV quantity configuration method based on real-time scheduling simulation and queuing theory that the embodiment of the present invention illustrates, comprises the following steps:

[0040] S1. Establish the simulation graph model of the AGV, and establish the path planning module, dynamic scheduling module, traffic management module and power management module of the AGV handling system in turn through the simulation software PlantSimulation;

[0041] details as follows:

[0042] S11. Establish the path planning module of the AGV handling system, such as selecting a one-way path grid, and planning a shortest directional path from its own position to the target node through the Dijkstra algorithm; to implement in the software, only need to modify the Transporter object attribute to Automatic Routing.

[0043] S12. Establish a dynamic scheduling module of the AGV handling system, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com