Pre-stressed secondary safety rope

A safety rope and pre-tightening technology, applied in safety belts, life-saving equipment, etc., can solve the problems of fast air flow, increase the difficulty of construction, reduce the safety of workers, and achieve the effect of preventing injuries and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical content of the present invention, specific embodiments are provided below, and the present invention is further described in conjunction with the accompanying drawings.

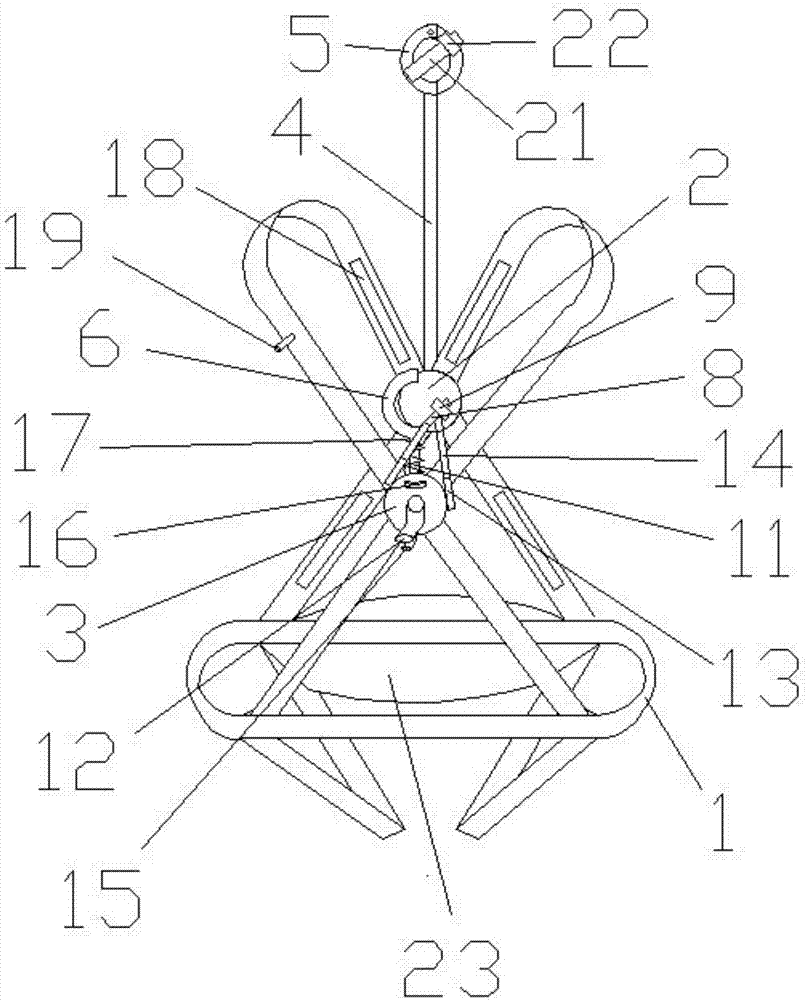

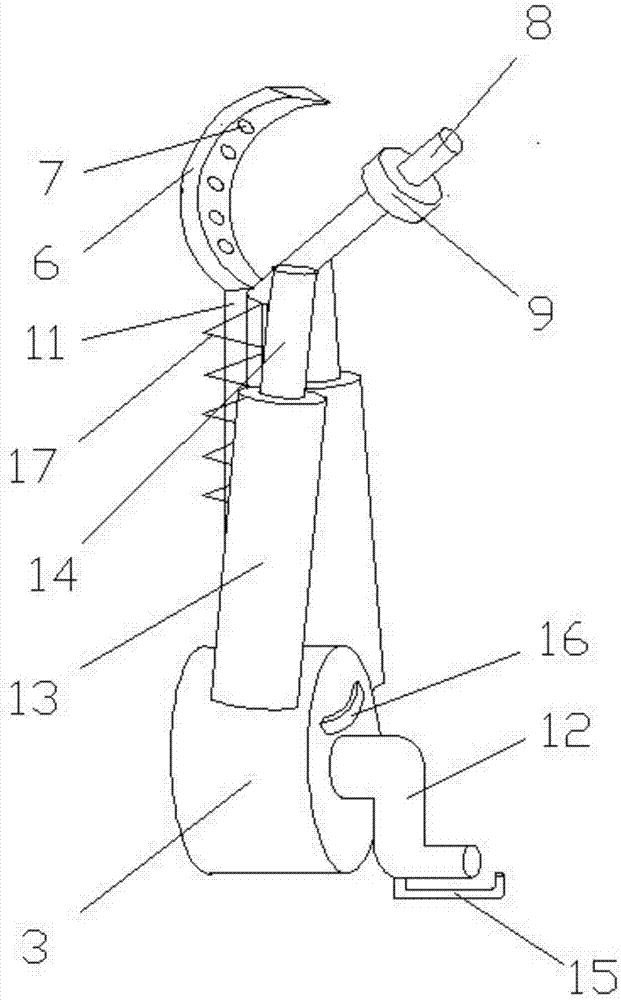

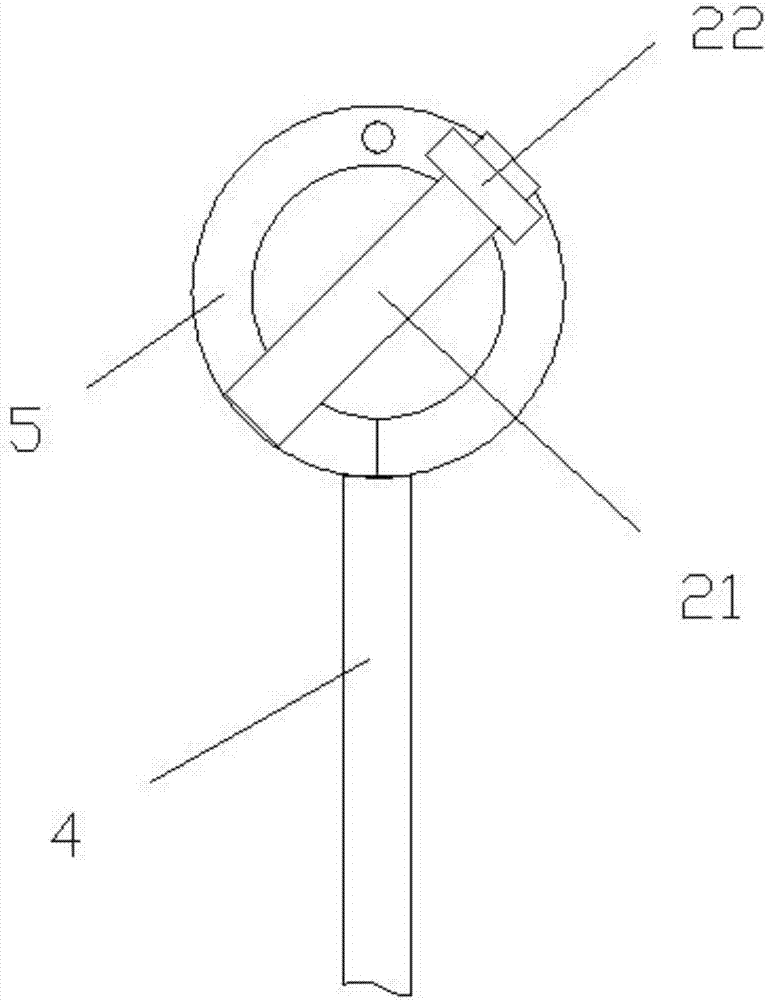

[0021] see Figure 1 to Figure 5 , the present invention provides a pre-tightened secondary safety rope, including a vest type safety belt 1, a retractor 2 and a rope reel 3, the retractor 2 is arranged at the rear of the vest type safety belt 1, The rope reel 3 is located at the front portion of the vest type safety belt 1, the first reel 4 is arranged in the retractor 2, and one end of the first reel 4 is provided with a buckle 5, so The retractor 2 can prevent the worker from self-locking when he falls rapidly, and prevent the worker from being injured after falling to the ground. The top of the rope reel 3 is provided with a locking mechanism, which prevents the worker from The rope reel 3 shakes during the construction process, and the rope reel 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com