Multi-mode hydrogen production water tank cleaning mechanism

A cleaning mechanism and multi-mode technology, which is applied to cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as low efficiency and trouble, and achieve high efficiency and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

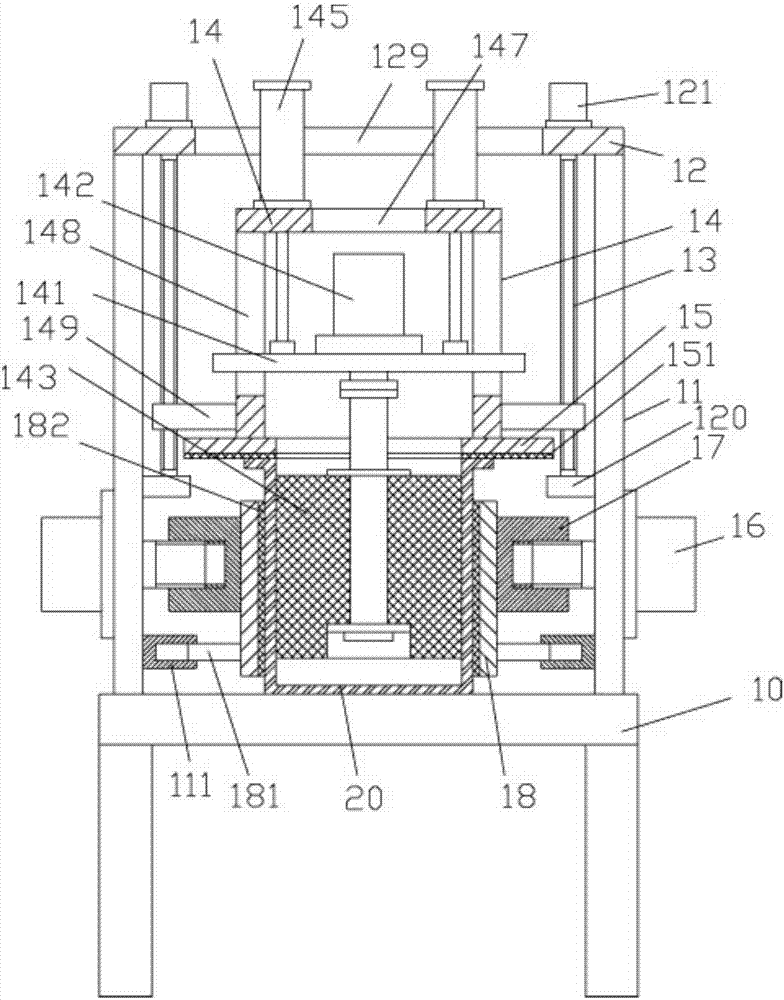

[0013] Examples, see e.g. figure 1 As shown, a multi-mode hydrogen production water tank cleaning mechanism includes a bottom frame 10. Vertical support plates 11 are fixed on both sides of the top plate of the bottom frame 10, and the upper top plate 12 is fixed on two vertical support plates. 11 on the top surface, the middle part of the vertical support plate 11 is fixed with a lower connecting plate 120, the bottom end of the adjusting screw 13 is hinged on the lower connecting plate 120, the bottom end of the adjusting screw 13 is hinged on the upper top plate 12, and the bottom of the upper top plate 12 The top surface is fixed with a lifting motor 121, the output shaft of the lifting motor 121 is a spline shaft, and the spline shaft is inserted into the spline hole at the top of the adjusting screw rod 13. The support frame 14 is below the upper top plate 12, and the support frame 14 Adjusting side plates 149 are fixed on the lower outer side walls of the two side plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap