A multi-furnace mixing plan matching device and method based on electrical signals

An electrical signal and matching device technology, applied in workpiece heating devices, manufacturing tools, metal rolling, etc., can solve the problems of poor accuracy, low automation level, high labor intensity, etc., to reduce workload, improve automation level, and match simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail now in conjunction with accompanying drawing.

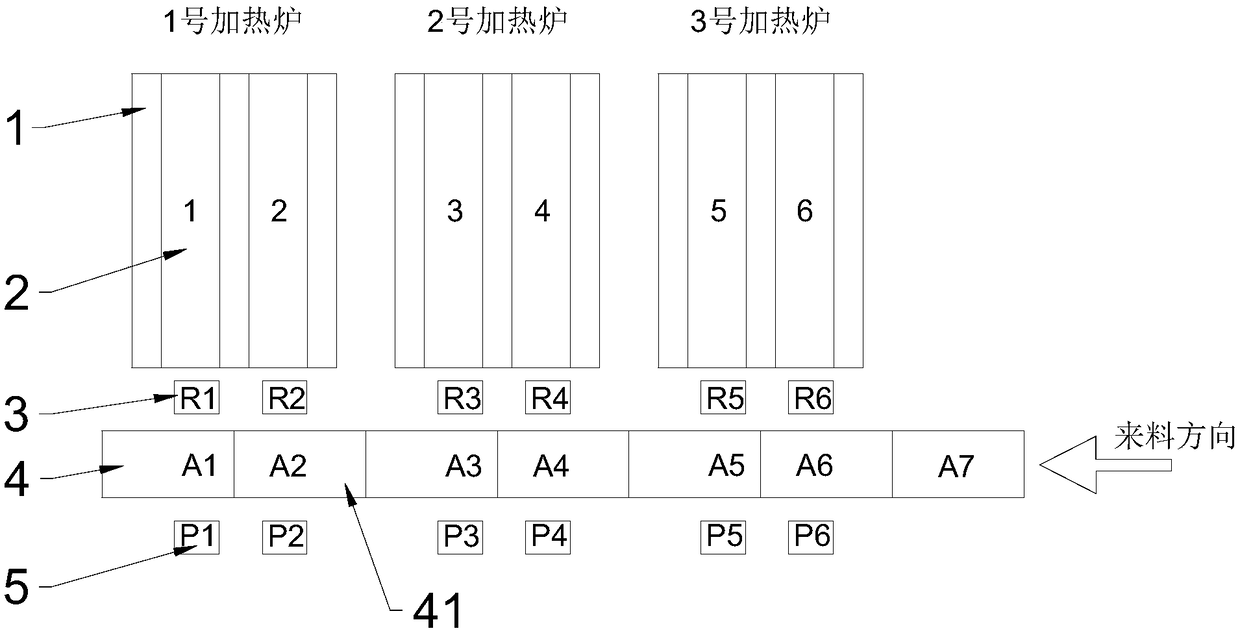

[0015] Such as figure 1 The shown is a multi-furnace mixed plan matching device based on electrical signals, which consists of three heating furnaces 1, No. 1 heating furnace, No. 2 heating furnace, and No. 3 heating furnace. Each heating furnace 1 has two passes. , there are 6 passes in total, from No. 1 heating furnace to No. 3 heating furnace, set as pass 1, pass 2, pass 3, pass 4, pass 5, pass 6, and the pass is the heating furnace The inner roller table or the heating area of the heating furnace or other structures for transporting steel billets. The furnace front roller table is composed of seven sections A1 to A7, of which A1 to A6 correspond to passes 1 to 6 respectively, and A1 to A7 Each section of the roller table in front of the furnace in A7 is individually controlled by the motor, which can rotate forward or reverse. In the secondary control system, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com