Punching machine for electric cooker shell

An electric rice cooker and punching machine technology, which is applied in the directions of punching tools, feeding devices, positioning devices, etc., can solve the problems of unguaranteed product quality, poor accuracy and high cost, so as to improve processing accuracy, increase production efficiency, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

[0028] This embodiment is applicable to the shell of the electric cooker that needs punching operation on three sides, wherein, front, back, left, and right are relative positions that are convenient for narration and adopt, to attach figure 1 The viewing angle is for reference.

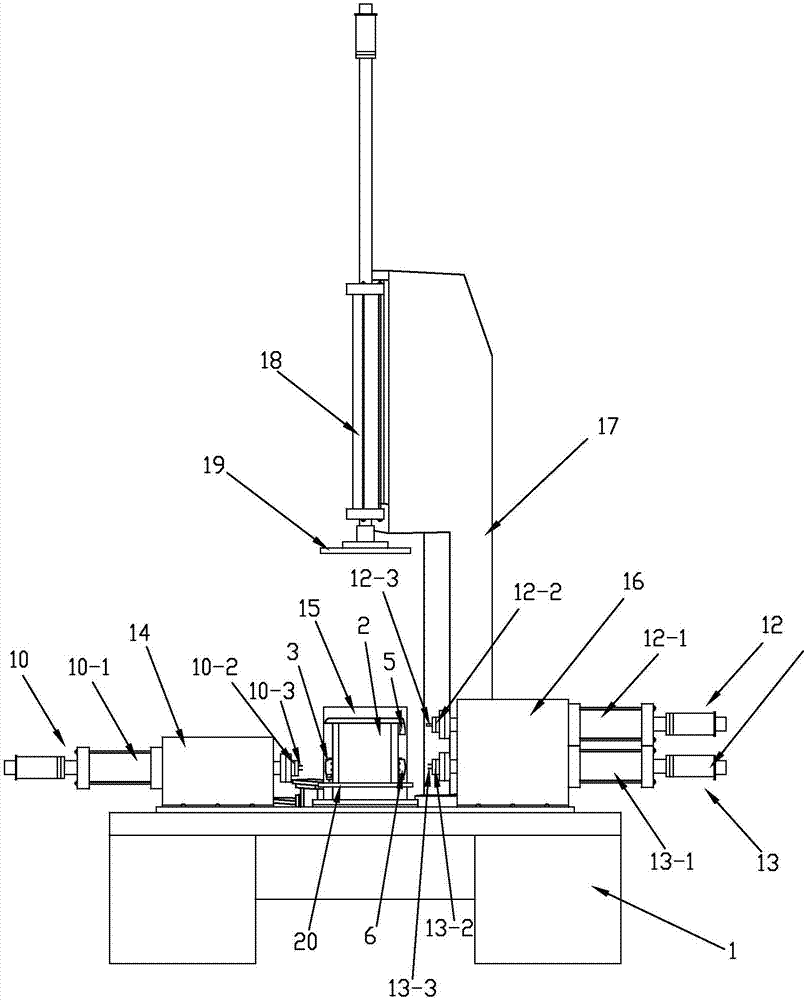

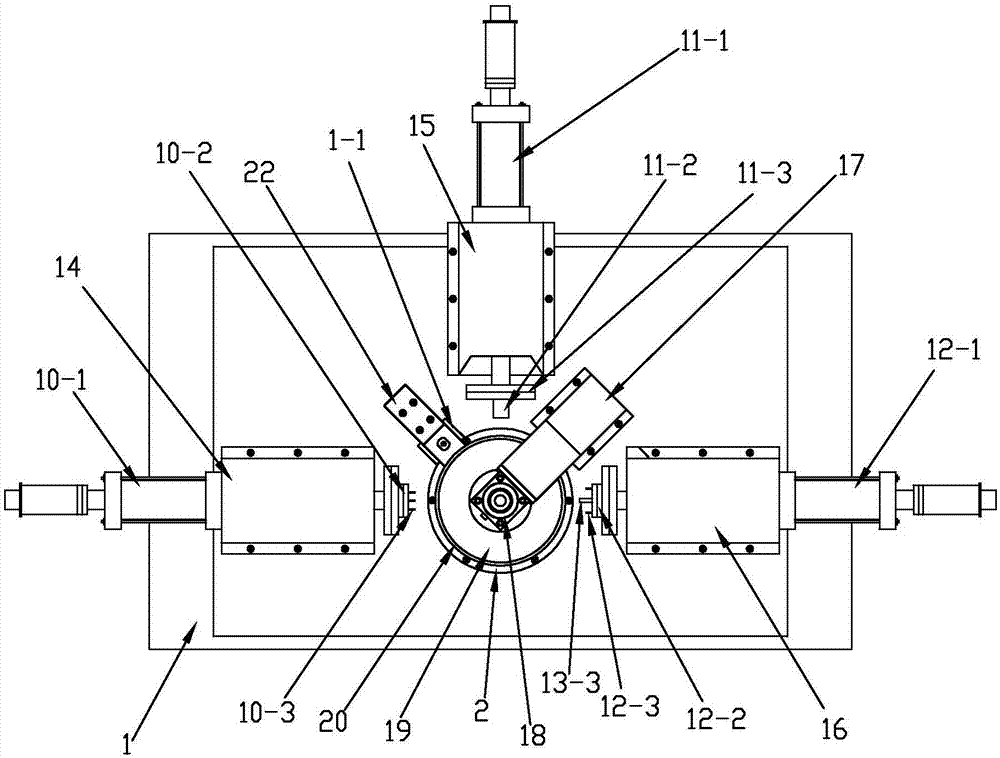

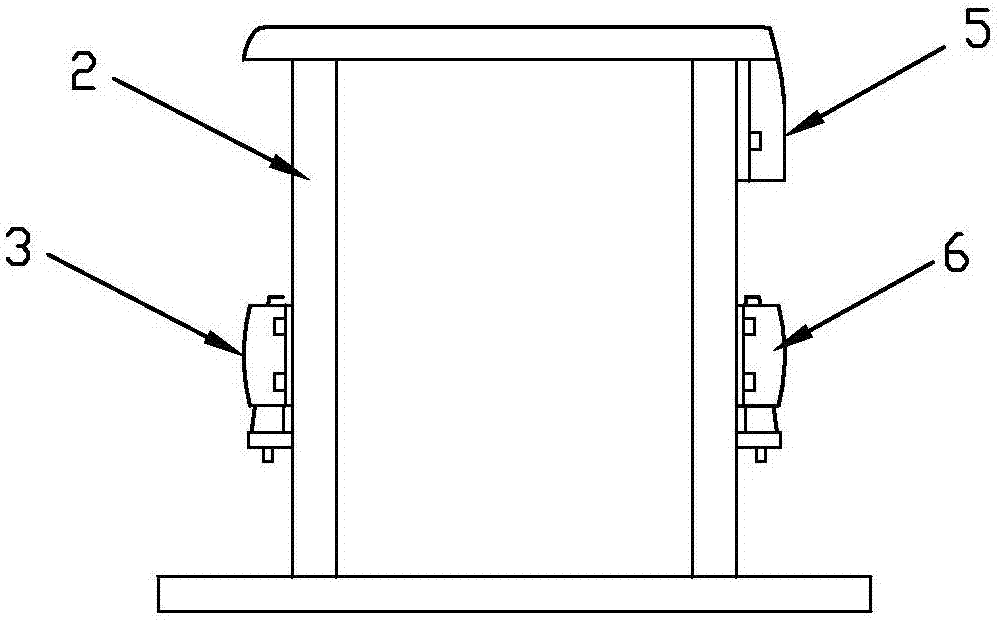

[0029] refer to Figure 1-9 :

[0030] A punching machine for the shell of an electric cooker, comprising a machine 1, the top of which is provided with a support 2, since the three sides of the shell of the electric cooker need to be punched, therefore, according to the required hole positions on each side of the shell of the electric cooker , hole shape and number of holes, the first and second fixed hole-shaped seats 4, 5 are respectively provided on the rear side and the top right side of the support 2, and the first , The second movable hole-shaped seat 3, 6;

[0031...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap