Jet printing mechanism nozzle adjusting device and adjusting system

A technology for adjusting devices and nozzles, which is applied in printing and other directions, can solve problems such as difficulty in ensuring the positioning accuracy of nozzle modules and platforms, and high requirements for nozzle calibration, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

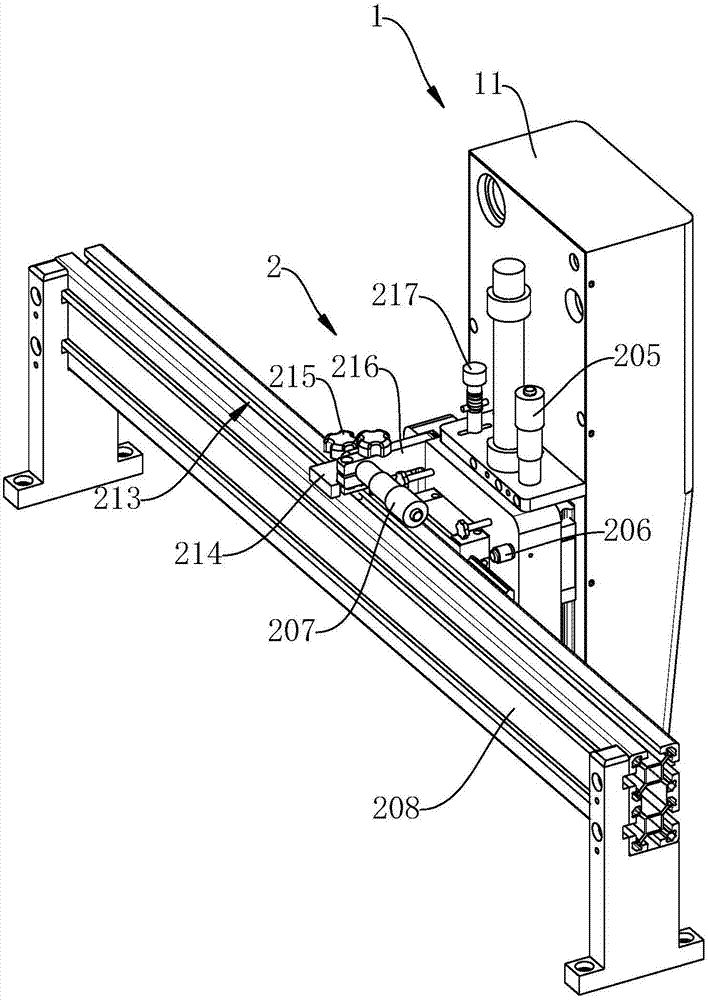

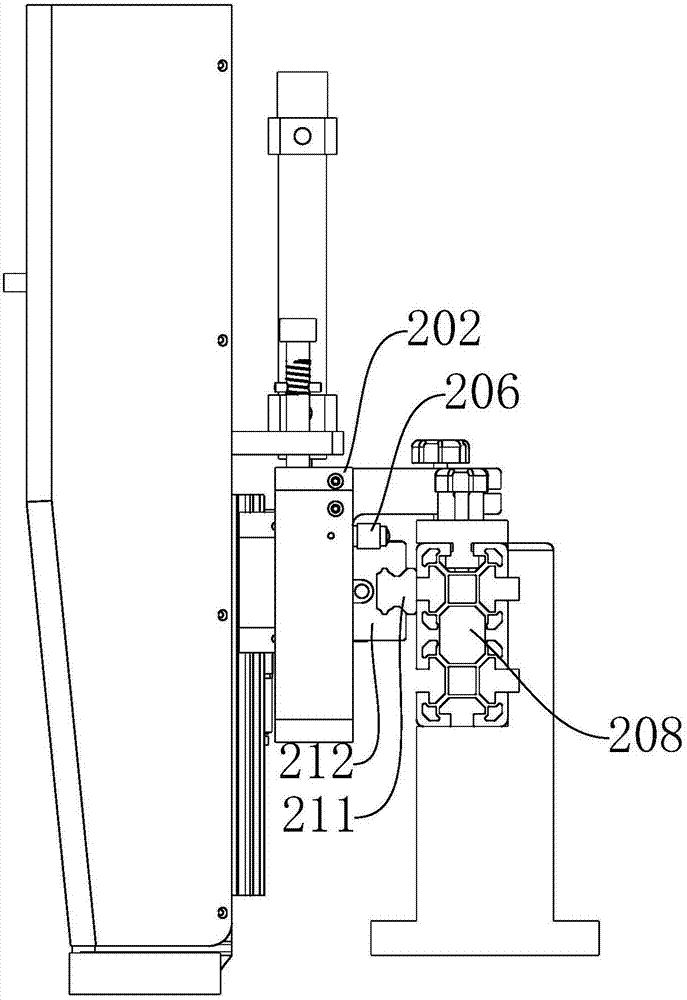

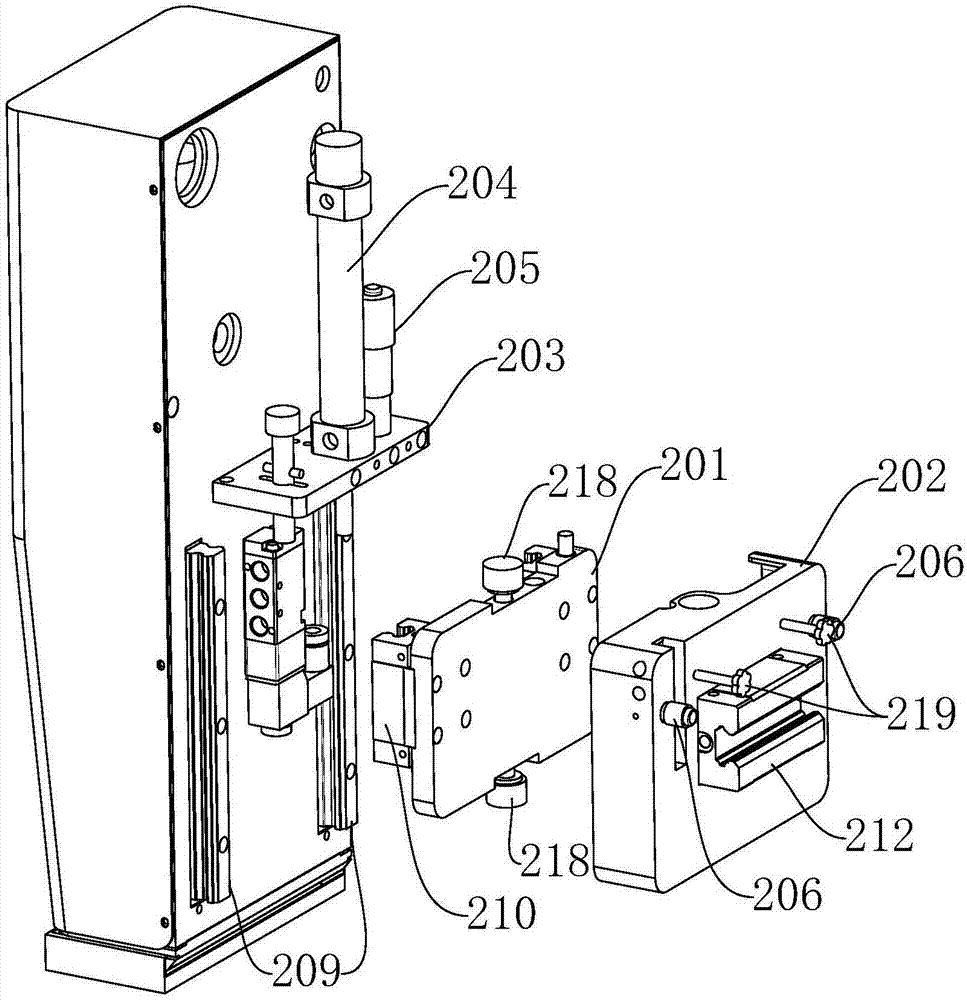

[0024] Figure 1-4 It shows the nozzle adjustment system of the printing mechanism of the present invention, including the printing mechanism 1 and the adjustment device 2 . The printing mechanism 1 includes a housing 11 and a printing head 12 . The housing 11 includes a backboard 111 and a bottom board 112 . The adjusting device 2 is connected to the back plate 111 , and the spray head 12 is installed on the bottom plate 112 .

[0025] The backboard 111 and the bottom board 112 are adjustably connected by two L-shaped connectors 113 . Such as Figure 4 As shown, one section of the two L-shaped connectors 113 is adjustably connected to the backboa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com