Safety type elevator maintenance control device

A technology for elevator maintenance and control devices, applied in transportation, packaging, elevators, etc., can solve problems such as increased elevator manufacturing costs, insufficient signal input ports, and complicated connection lines, so as to improve efficiency, facilitate connection, and reduce the cost of connecting cables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, realization principle, purpose and effect of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

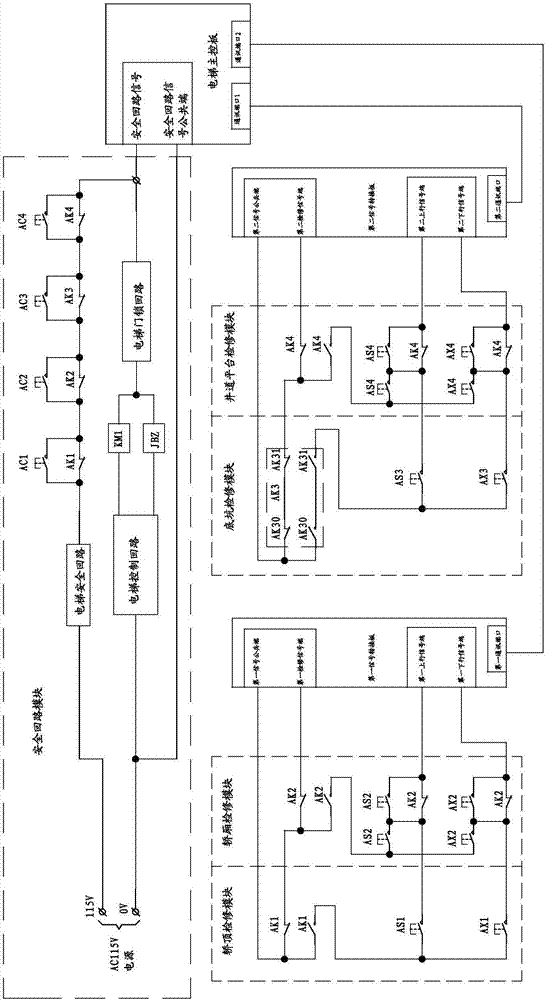

[0020] The invention discloses a safe elevator maintenance control device, such as figure 1 As shown, it includes several inspection modules and safety circuit modules. The inspection module includes a car top inspection module, a car inspection module, a pit inspection module, a hoistway platform inspection module, and a first signal adapter board installed on the car top and installed on the The second signal adapter board of the bottom pit; in each inspection module, there are inspection switches AK1, AK2, AK3, AK4 for controlling the elevator to enter or exit the inspection state, and up button switches AS1, AS2, AS3 for controlling the upward inspection of the elevator , AS4, and the downward button switches AX1, AX2, A...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap