Self-adaptive thermal camouflage coating and preparation method thereof

A self-adaptive and heat-adaptive technology, applied in the field of camouflage and stealth, can solve problems such as construction difficulties, and achieve the effects of convenient construction, material saving and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

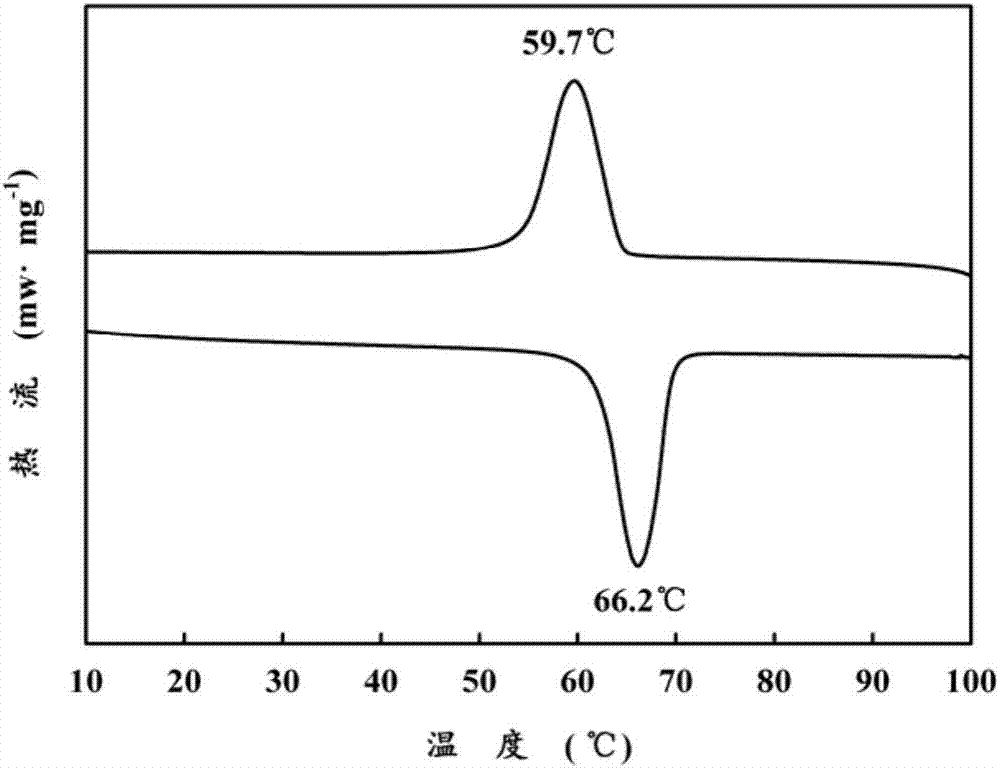

Embodiment 1

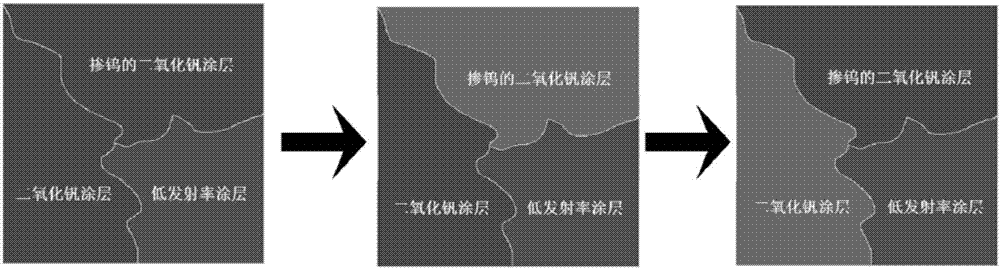

[0037] An adaptive thermal camouflage coating of the present invention, the adaptive thermal camouflage coating is located on the base tarpaulin, the adaptive thermal camouflage coating is mainly composed of vanadium dioxide coating, tungsten-doped vanadium dioxide coating and The low-emissivity coating is formed by depositing vanadium dioxide ink, tungsten-doped vanadium dioxide ink and low-emissivity ink on the surface of the base tarpaulin by inkjet printing according to the designed camouflage pattern; the adaptive thermal The thickness of the camouflage coating is 25 μm.

[0038] The preparation method of the adaptive thermal camouflage coating of the present embodiment comprises the following steps:

[0039] (1) Preparation of vanadium dioxide ink: Mix 5g vanadium dioxide nanopowder and 180g diluent (a mixture of xylene and butyl acetate with a volume ratio of 4:1) and ultrasonically disperse for 20min, then add 0.3g BYK oily dispersant (The model is DISPERBYK-110), dis...

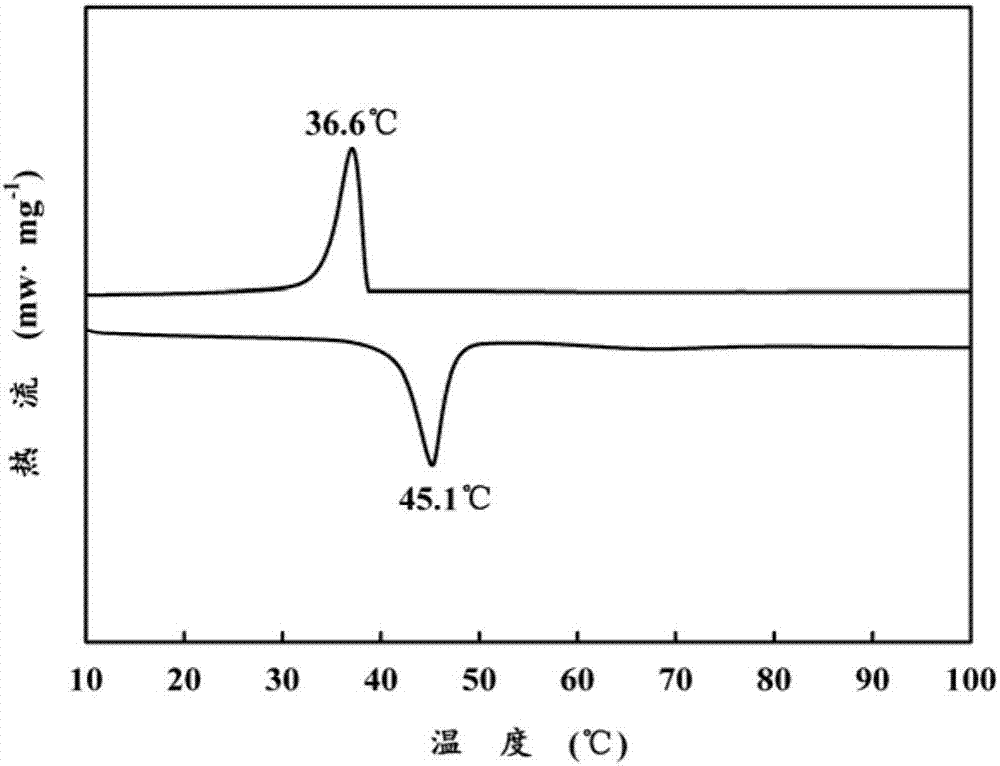

Embodiment 2

[0047] An adaptive thermal camouflage coating of the present invention, the adaptive thermal camouflage coating is located on the base tarpaulin, the adaptive thermal camouflage coating is mainly composed of vanadium dioxide coating, tungsten-doped vanadium dioxide coating and The low-emissivity coating is formed by depositing vanadium dioxide ink, tungsten-doped vanadium dioxide ink and low-emissivity ink on the surface of the base tarpaulin by inkjet printing according to the designed camouflage pattern; the adaptive thermal The thickness of the camouflage coating is 50 μm.

[0048] The preparation method of the self-adaptive thermal camouflage coating of the present embodiment specifically comprises the following steps:

[0049] (1) Preparation of vanadium dioxide ink: 5g vanadium dioxide nanopowder and 180g diluent (xylene and butyl acetate with a volume ratio of 4:1) were mixed and ultrasonically dispersed for 20min, and then 0.3g BYK oily dispersant was added ( The mode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com