Underwater concrete pouring piling machine

A technology of underwater concrete and pile driving, which is applied in construction, sheet pile walls, foundation structure engineering, etc. It can solve problems such as failure to meet requirements, troublesome control, and failure to meet production needs, so as to achieve automatic control and reduce labor and the effect of material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

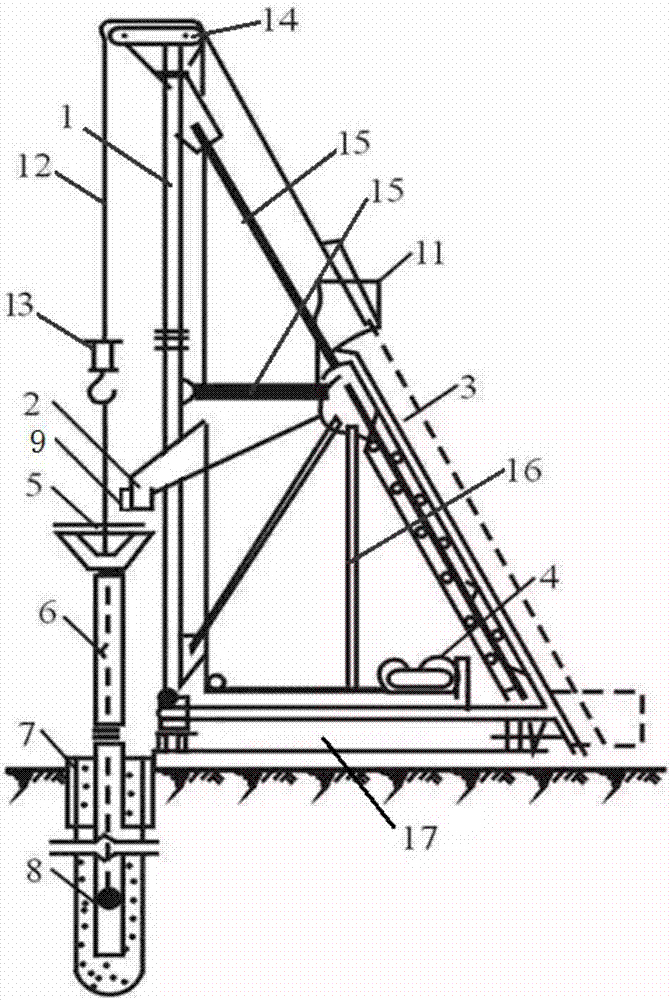

[0020] like figure 1 The shown a kind of underwater concrete pouring pile driver of the present invention comprises a machine base 17, a frame 1 is arranged vertically on the said machine base 17, and a conveyor belt 3 is arranged on the rear side of the said machine base 17 obliquely, so that The upper end of the conveyor belt 3 is provided with a cover plate 11, the lower side of the feeding port of the conveyor belt is provided with a feeding hopper 2, the upper end of the frame 1 is also provided with a wheel plate 14, and a cable is slidably arranged on the wheel plate 14. Line 12, the lower end of the cable 12 is connected with a hook 13, the lower end of the hook 13 is hung with a funnel 5 by a sling, the funnel 5 is located below the feeding hopper 2, and the feeding hopper 2 faces Funnel 5 direction is provided with inductor 9, and this inductor 9 selects the inductor 9 that can sense object distance, is used for sensing the height of material in funnel 5, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com