A Multistage Axial Flow Compressor with Self-Adaptive Blowing and Suction of Front and Rear Stage Stators

An axial flow compressor, self-adaptive technology, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of non-adaptive, limited range of working conditions, difficult engineering realization, etc., to achieve broad and effective work The range of operating conditions, the limited range of avoiding operating conditions, and the effect of avoiding stall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

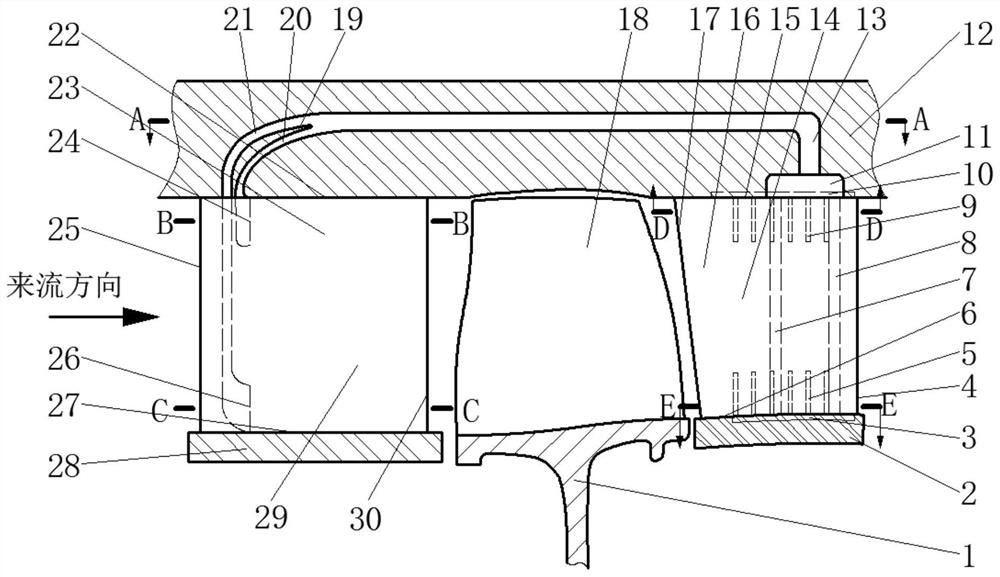

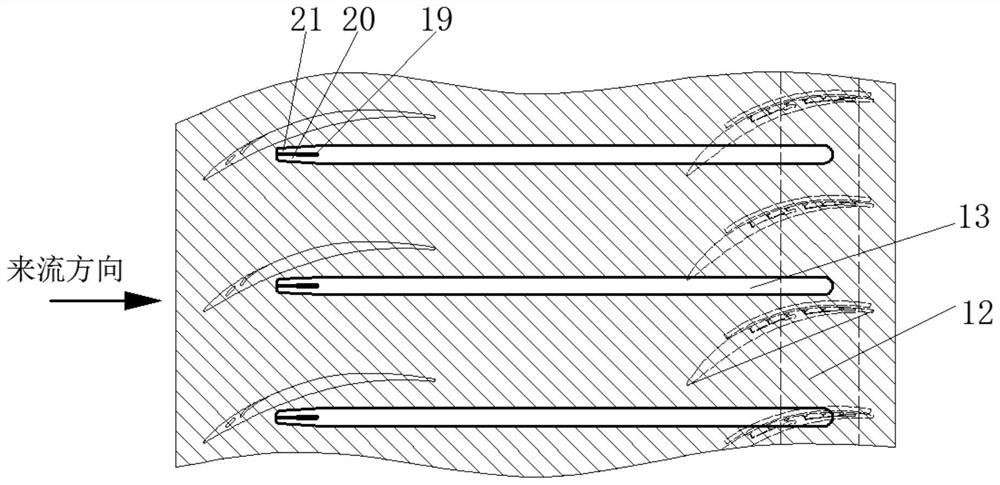

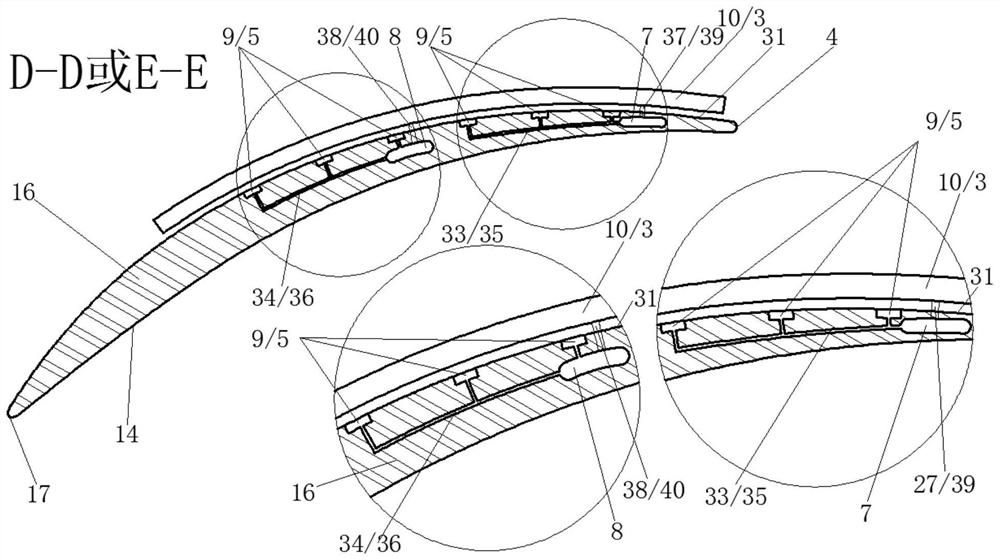

[0026] like figure 1 As shown, the multi-stage axial flow compressor of the present invention includes the front stage stator blade 23, the rotor blade 18, the rear stage stator blade 16, the casing 12 and the air induction pipe 13, 20, 21 structure located inside the casing 12; One side of the stage stator blade 23 is connected to the casing 12 and has a casing side end wall 22, and the other side is connected to the hub 28 and has a hub side end wall 27; the rotor blade 18 is located downstream of the front stage stator blade 23 and passes through the rotor wheel The disk 1 is connected to the engine shaft, and there is a blade tip gap between the rotor blade 18 and the casing 12; the rear stage stator blade 16 is located downstream of the rotor blade 18, and one side of the stator blade 16 is seamlessly connected with the casing 12, and has a casing side end wall 15, the other side is connected with the hub 2 and has a hub-side end wall 6.

[0027] On the side of the sucti...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, except that there are multiple rotor-stator stages between the front stage stator and the rear stage stator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com