ZZJX novel pressing type fast pipe joint

A press-type, pipe joint technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of inconvenient assembly, high production cost, complex structure of pipe connectors, etc., and achieve low production cost, convenient operation, and easy connection and sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

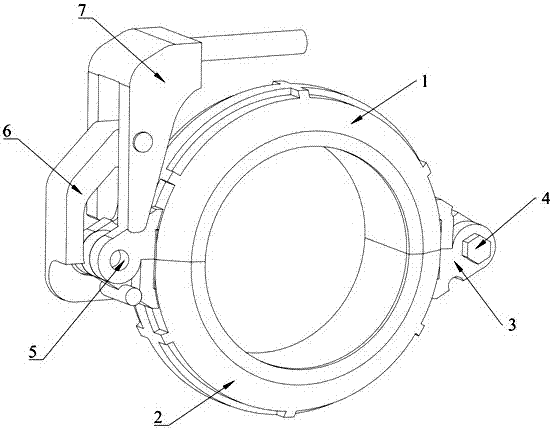

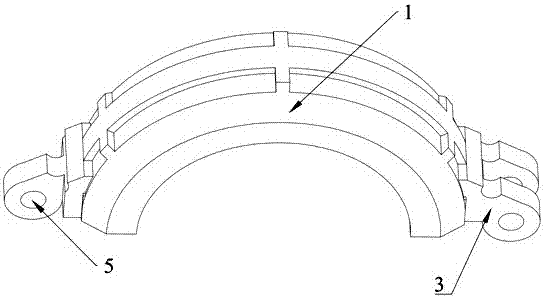

[0011] like figure 1 , 2 Shown: ZZJX new push-type quick pipe joint, the structure includes: first semi-circular ring 1, second semi-circular ring 2, side ear 3, fastening bolt 4, circular hole 5, buckle 6, locking handle 7; Both the first semi-circular ring 1 and the second semi-circular ring 2 are designed with a C-type casting structure, and one end of the first semi-circular ring 1 and the second semi-circular ring 2 is provided with a side ear 3, and the first semi-circular ring 1 and the second semi-circular ring 2 are provided with side ears 3. The side ears 3 at the ends of the semicircular ring 1 and the second semicircular ring 2 are integrally structured with the first semicircular ring 1 and the second semicircular ring 2 respectively, and the first semicircular ring 1 and the second semicircular ring The side ear 3 at the end of 2 is provided with a through hole for receiving the fastening bolt 4 in the direction of the transverse axis, and the diameter of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com