Indoor wiring structure and wiring method

A technology for indoor wiring and steel structure, applied in the direction of electrical components, etc., can solve the problems of troublesome maintenance and affecting the appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

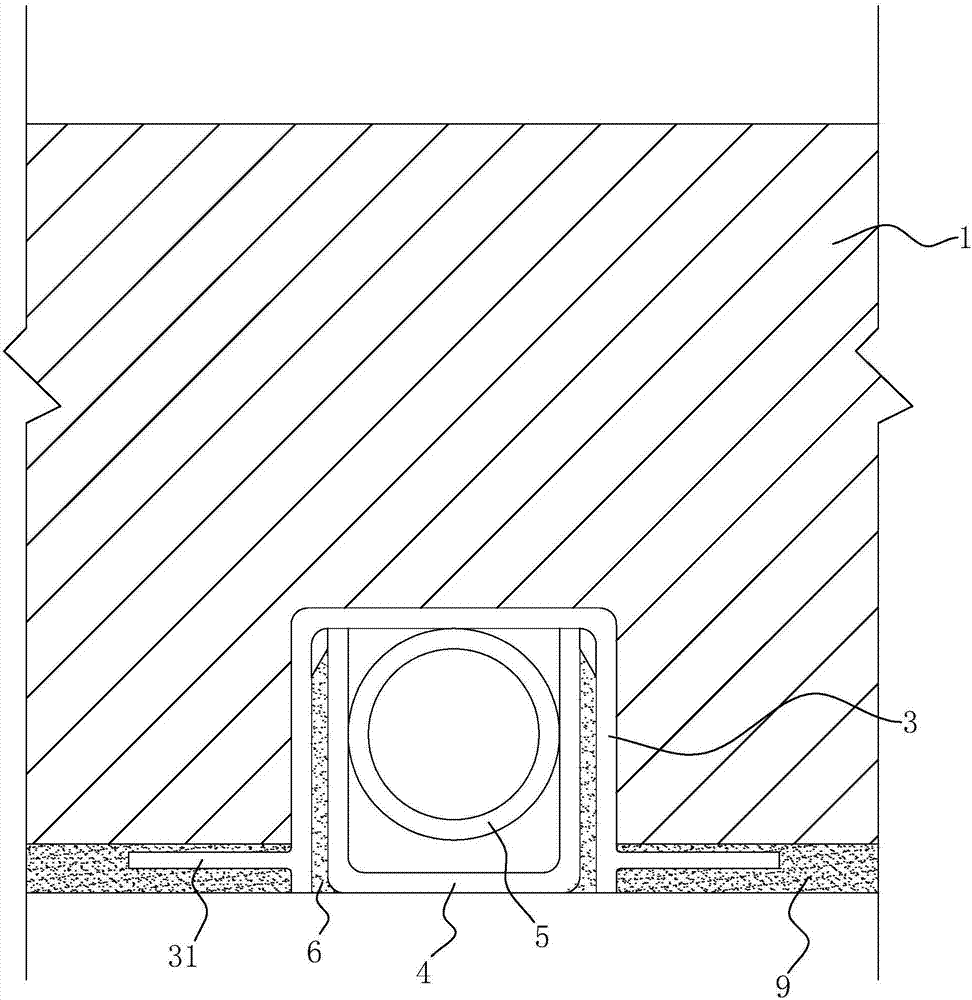

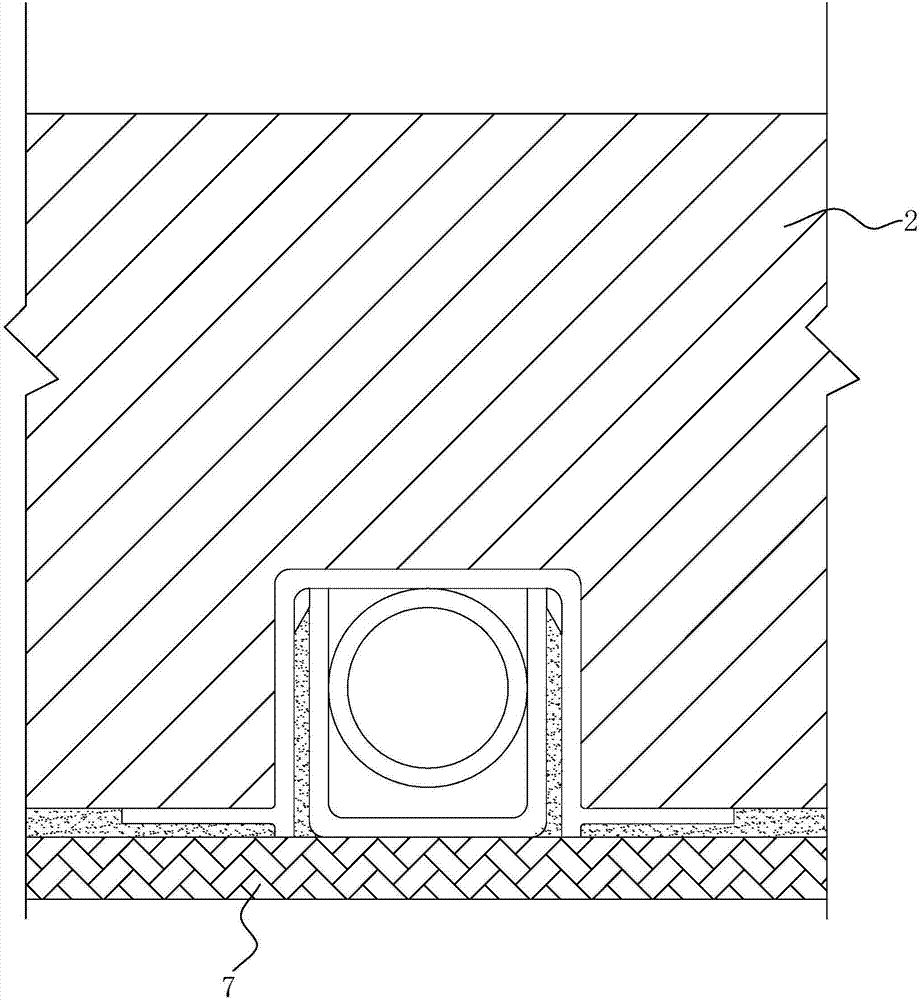

[0039] Embodiment 1: a kind of indoor wiring structure, such as figure 1 and figure 2 As shown, the steel structure support frame 3 is included, the steel structure support frame 3 is installed in the tank body provided on the wall body 1 or the ground 2, and an installation groove for the installation of the pipeline 5 is arranged on the steel structure support frame 3, the width of the installation groove Depends on the number of pipelines 5 installed in the installation groove.

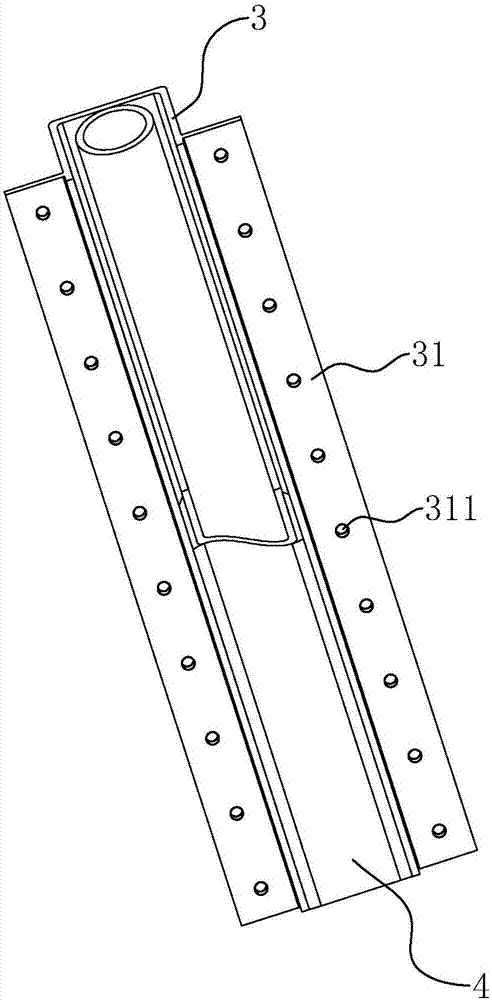

[0040] refer to image 3 , both sides of the steel support frame 3 are provided with a fixed plate 31 perpendicular to the outer wall, the distance between the fixed plate 31 and the opening edge of the installation groove is 0-8mm, and the distance is determined according to the usage conditions. Such as figure 2 As shown, the steel support frame 3 installed on the ground 2, the distance between the fixed plate 31 and the opening edge of the installation groove is 0-2mm; figure 1 As shown, t...

Embodiment 2

[0044] Embodiment 2: An indoor wiring structure and wiring method, comprising the following steps:

[0045] S1, marking, first design the design drawing of the pipeline 5 layout according to the indoor situation, and then make slotting marks at the corresponding position of the wall body 1 according to the design drawing;

[0046] S2, slotting, according to the setting quantity and size of the pipeline 5, adjust the slotting width and depth of the slotting machine, and then use the slotting machine to open a slot body on the wall 1 or the ground 2 along the mark;

[0047]S3. Install the steel structure support frame 3, coat concrete on the outside of the steel structure support frame 3 with prefabricated length and width, pour concrete into the tank body, and fix it in the tank body;

[0048] When installing the steel structure support frame 3, if the steel structure support frame 3 is installed on the wall body 1, the steel structure support frame 3 with a distance of 2-6 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com