A special admixture for self-compacting and non-shrinkage steel tube concrete

A technology for steel tube concrete without shrinkage, which is applied in the field of self-compacting and non-shrinkage steel tube concrete admixtures. It can solve the problems of high gas generation speed, hydrogen embrittlement damage of steel structure, and insufficient comprehensiveness when mixed with aluminum powder, so as to improve workability. , Increased viscous resistance, ensuring tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

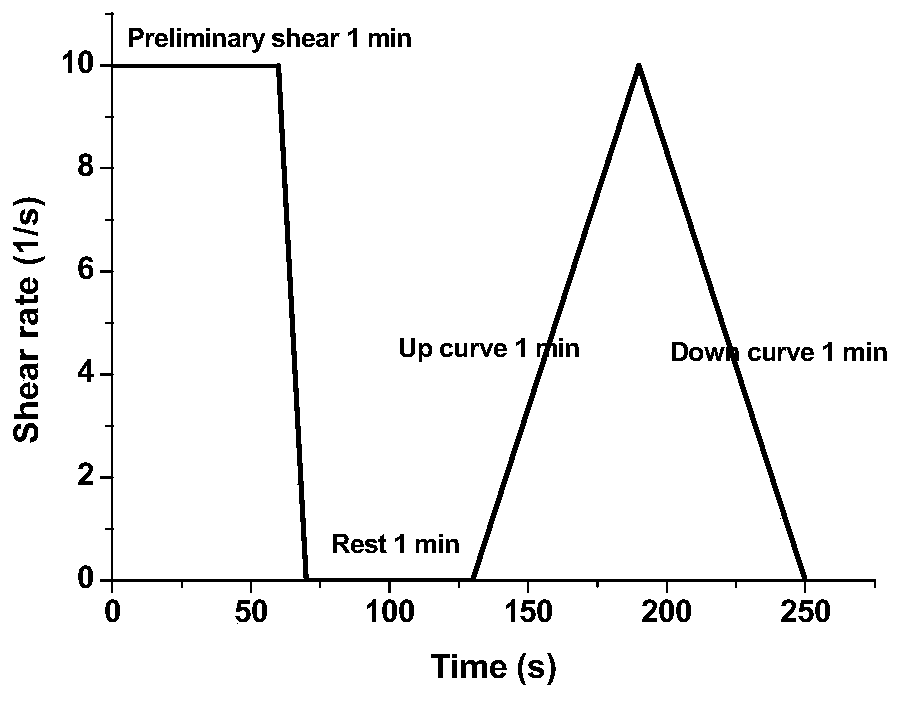

Image

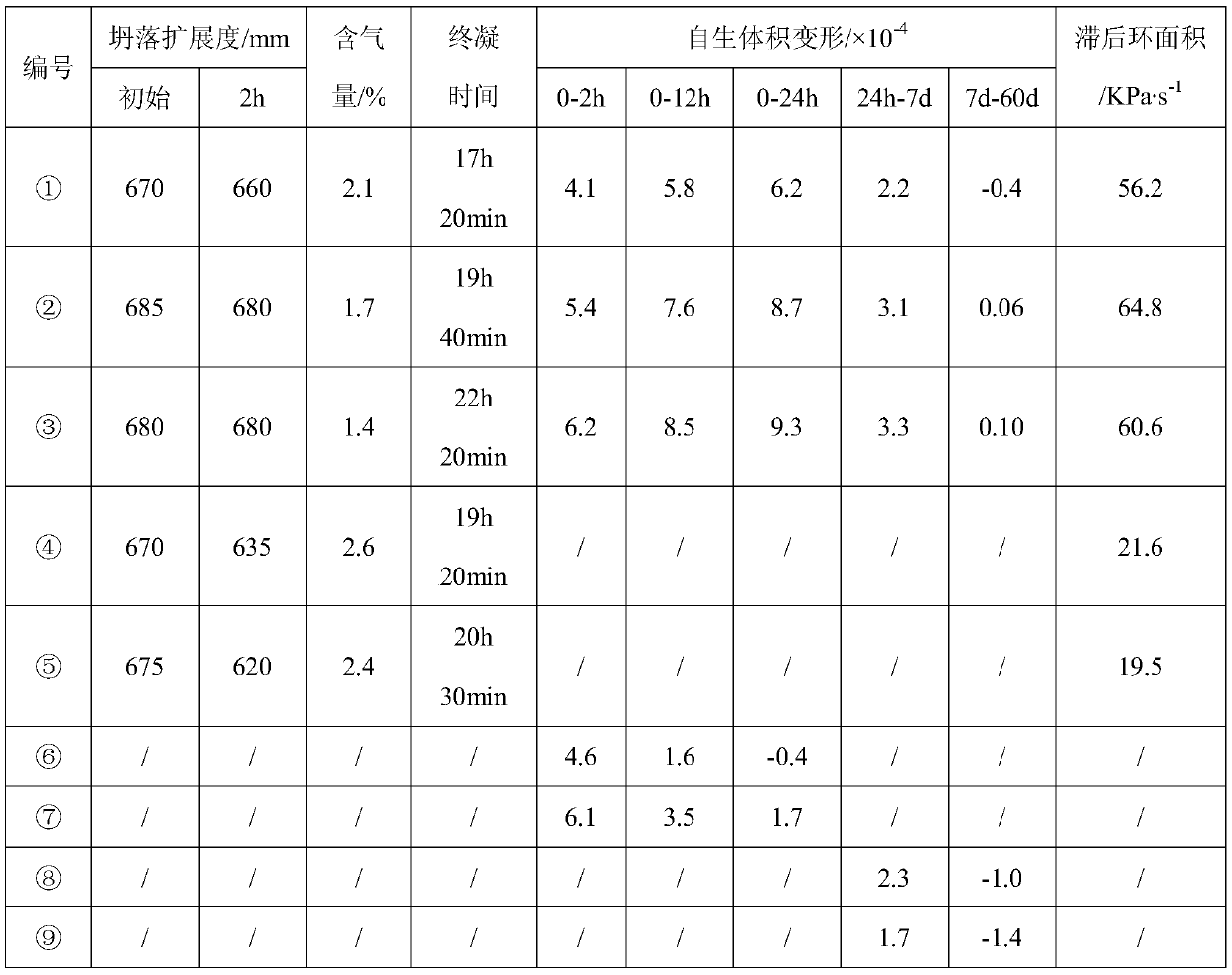

Examples

Embodiment 1

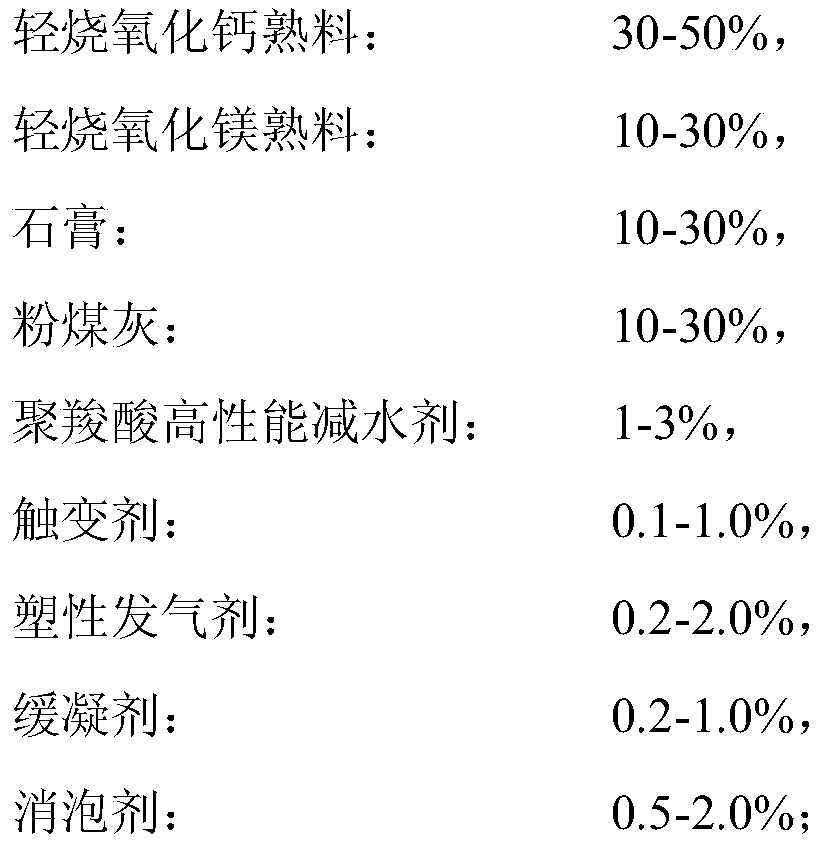

[0035] Light-burned calcium oxide clinker: 30%, light-burned magnesium oxide clinker: 15%, gypsum: 25%, fly ash: 26.7%, PCA-100P: 1.5%, HP-60 guar gum: 0.4%, AC Foaming agent: 0.5%, glucose: 0.4%, P803: 0.5%.

Embodiment 2

[0037] Light-burned calcium oxide clinker: 40%, light-burned magnesia clinker: 20%, gypsum: 15%, fly ash: 19.3%, PCA-200P: 2.5%, KELCO-DG dinitrate: 0.6%, AC Foaming agent: 1.0%, sodium gluconate: 0.6%, P8850: 1.0%.

Embodiment 3

[0039] Light-burned calcium oxide clinker: 45%, light-burned magnesium oxide clinker: 25%, gypsum: 10%, fly ash: 13.4%, PCA-200P: 2.5%, KELZAN xanthan gum: 0.8%, AC foam Agent: 1.5%, sodium hexametaphosphate: 0.8%, P8850: 1.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com