Wide range shooting body and shooting device

A projectile and high-range technology, which is applied in the direction of weapon accessories, cartridge ammunition, ammunition, etc., can solve the problem that projectiles cannot achieve interval and step-by-step ignition boosting, and achieve the effect of improving flight stability and shooting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

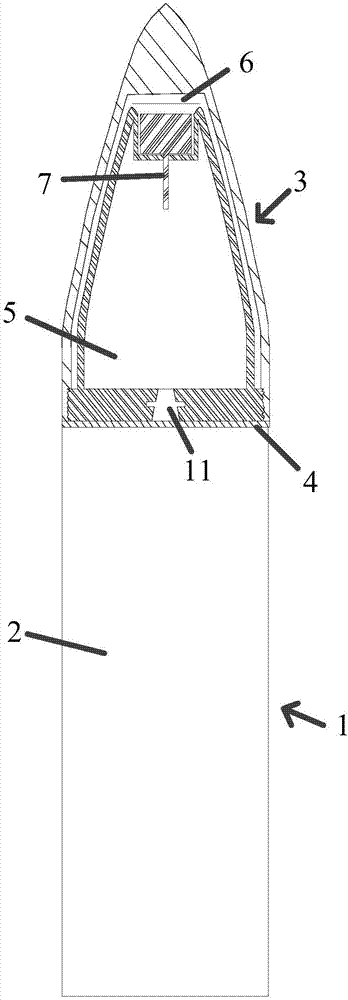

[0038] This embodiment provides a high-range emitter, such as figure 1 and figure 2 shown, which includes

[0039] Projectile body 1, the inner cavity of the projectile body 1 is provided with a primary motive medium 2, and the primary motive medium 2 explodes to push the launch head 3 to fly out of the cavity of the pistol;

[0040]Emitter 3 is arranged on the front end of the projectile body 1, and the emitter 3 is made of metal material; the inner cavity of the emitter 3 is provided with a power chamber 8 made of thermal insulation material, and the secondary motive medium 5 is arranged inside the power chamber 8 . The inner cavity of the emitting head 3 is also provided with a double gold sheet 6 and a heat conduction excitation rod 7, a gap is provided between the double gold sheet 6 and the heat conduction excitation rod 7, and the heat conduction excitation rod 7 extends from the outside of the power chamber 8 The power chamber 8 is also connected to the secondary ...

Embodiment 2

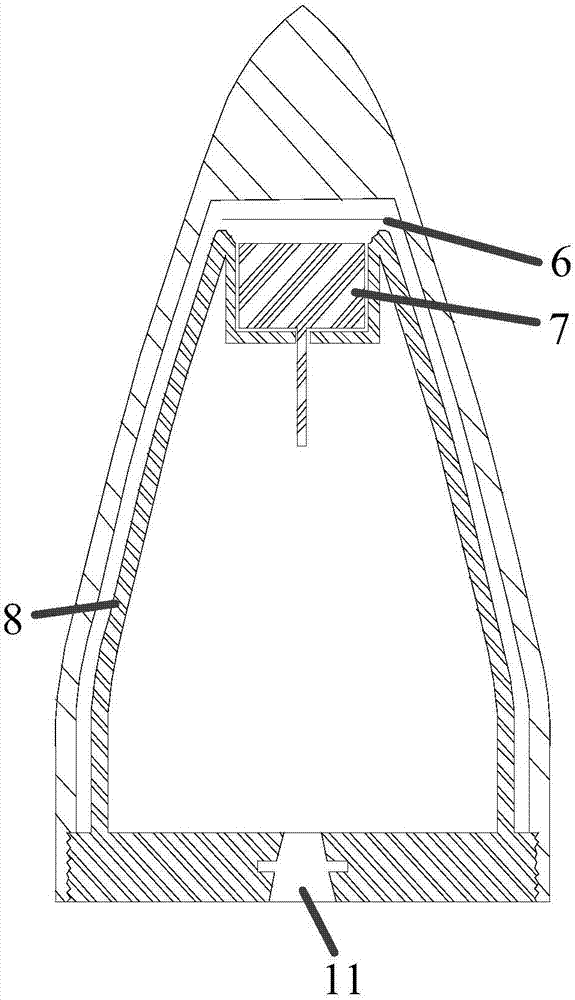

[0050] This embodiment provides a high-range emitter, which includes

[0051] Projectile body 1, the inner cavity of the projectile body 1 is provided with a primary motive medium 2, and the primary motive medium 2 explodes to push the launch head 3 to fly out of the cavity of the pistol;

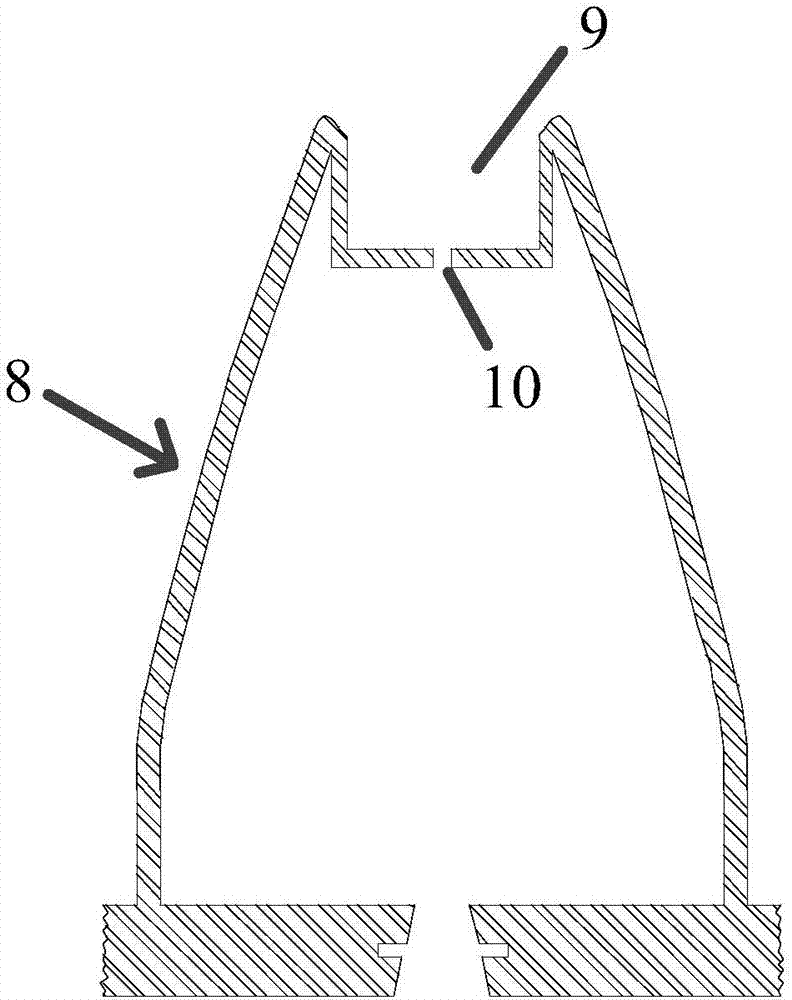

[0052] Emitter 3 is arranged on the front end of the projectile body 1, and the emitter 3 is made of metal material; the inner cavity of the emitter 3 is provided with a power chamber 8 made of thermal insulation material, and the secondary motive medium 5 is arranged inside the power chamber 8 . The inner cavity of the emitting head 3 is also provided with a double gold sheet 6 and a heat conduction excitation rod 7, a gap is provided between the double gold sheet 6 and the heat conduction excitation rod 7, and the heat conduction excitation rod 7 extends from the outside of the power chamber 8 The power chamber 8 is also connected to the secondary power medium 5 .

[0053] Wherein, a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com