Method and system for managing regeneration of particulate filters

A particle filter and regeneration process technology, applied in the electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, exhaust treatment, etc., can solve the problems of fuel consumption impact, internal combustion engine damage, impact, etc. Achieve the effect of extending the replacement interval and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

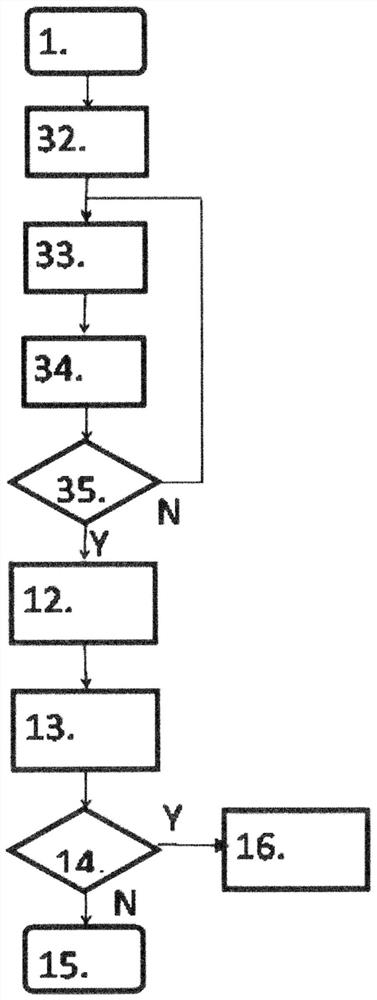

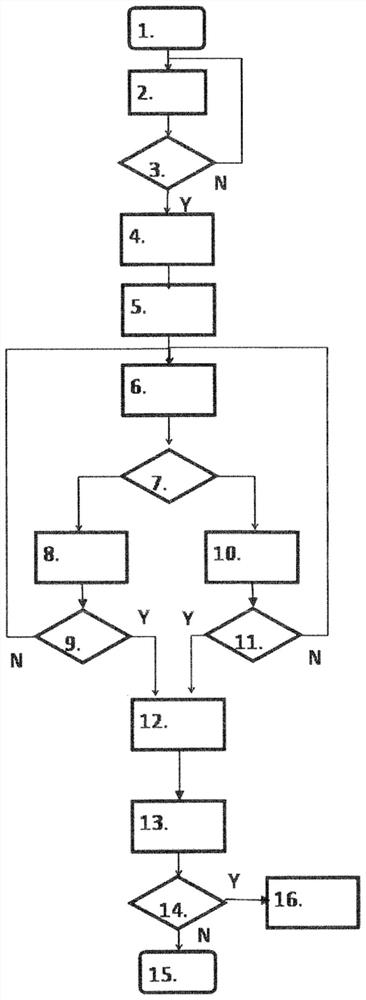

[0031] The method of the present invention is now described, which is automatically activated (1 start) when the regeneration process of the vehicle's DPF is initiated. After its activation, the method runs continuously and stops when the regeneration process is interrupted by the method.

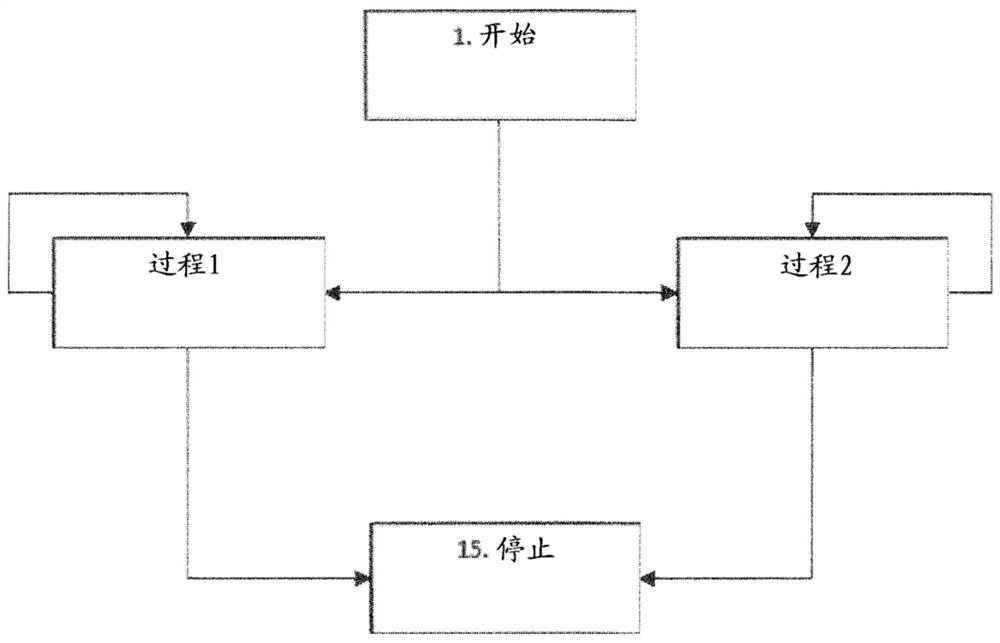

[0032] refer to figure 1 , start the following two parallel processes: one based on the estimated temperature at the outlet of the particulate filter (process 2), and the other based on the calculated pressure difference between the inlet and outlet of the particulate filter (process 1).

[0033] The first process, indicating that the regeneration of the filter is reasonably complete, forces an interruption of the regeneration process.

[0034] According to a preferred embodiment of the invention, in case one of the two processes detects an error in the sensor on which it is based, this process is stopped without affecting the operation of the other process. This makes it possible not on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com