Steel post having corrosion control property for embedded part

A technology of embedded parts and steel columns, applied to layered products, devices for coating liquid on the surface, signboards, etc., can solve problems such as corrosion, achieve the effect of prolonging the life of materials, avoiding traffic jams, and extending replacement intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

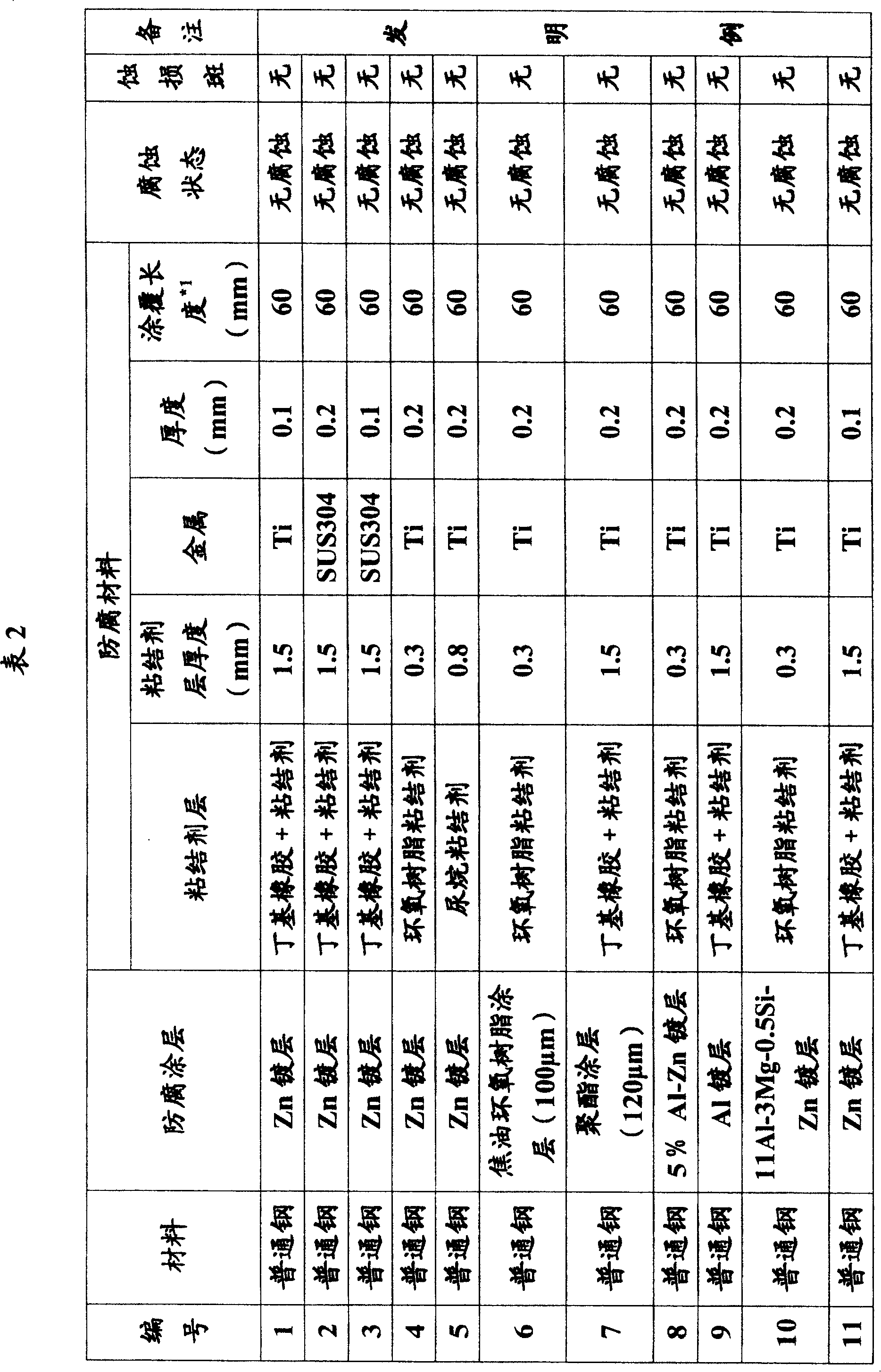

Embodiment 1

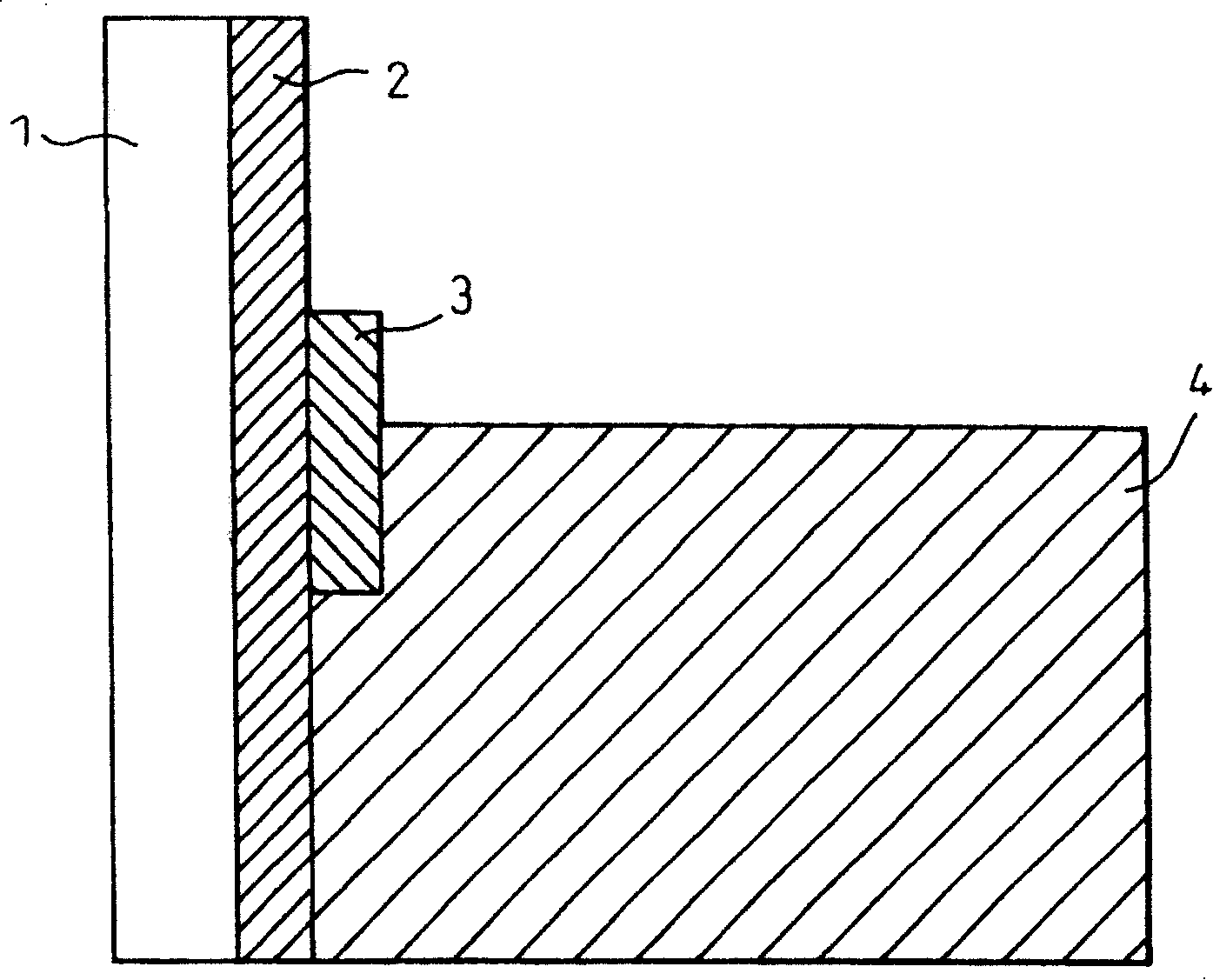

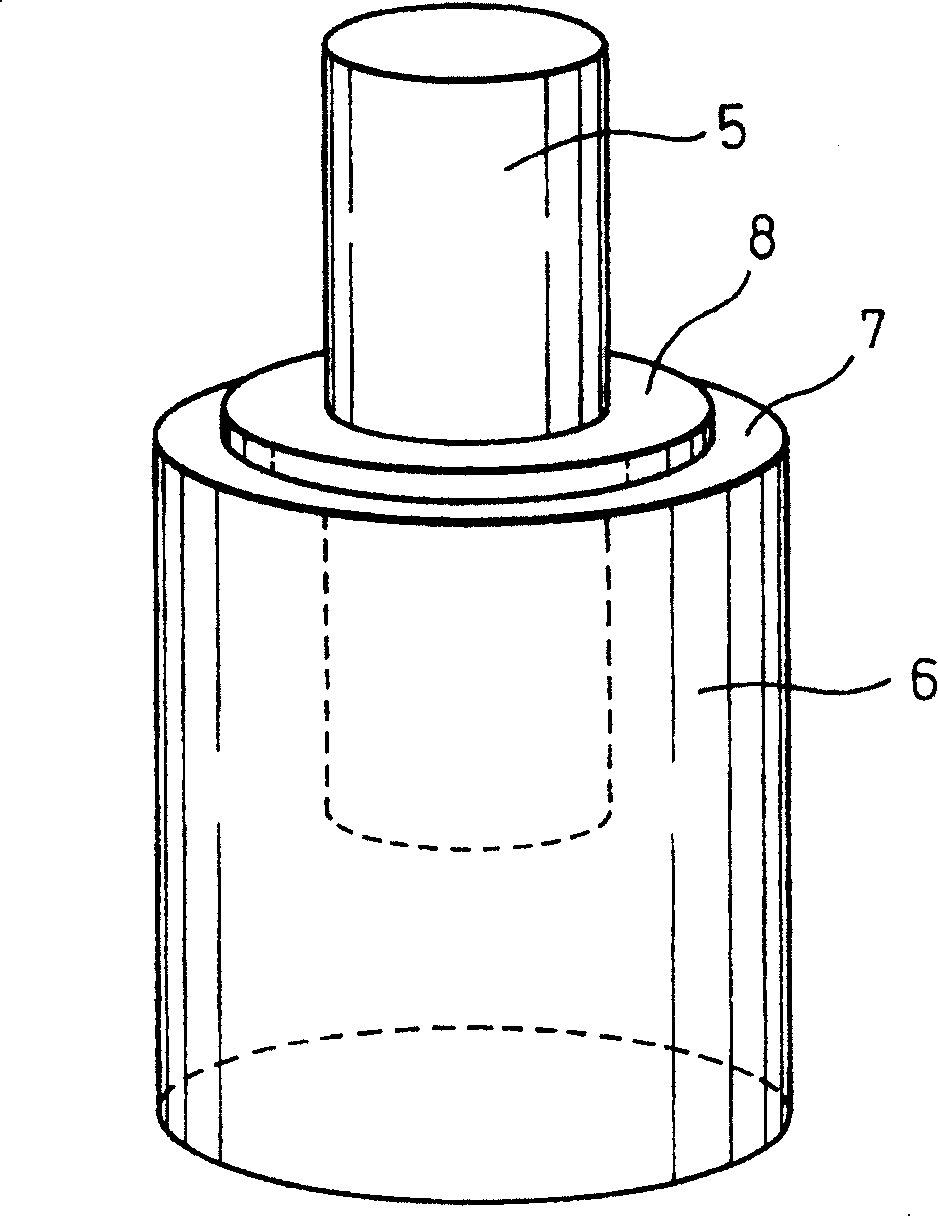

[0031] manufacture figure 2 Test samples shown. Test sample 5 (steel column) has an outer diameter of 60.5 mm, a length of 200 mm, and a thickness of 3.8 mm. Test sample 5 was first coated with the anti-corrosion coating shown in Table 2, and then further covered with the metal-based anti-corrosion material shown in Table 2. The sample was buried in concrete 6 with a diameter of 100 mm to approximately half its length of 200 mm. In addition, a 20mm high PVC frame 7 is placed on the concrete. The frame 7 is filled with an embedding material 8 composed of a mixture of commercially available horticultural soil, decayed leaves, and the like. The test sample was sprayed once daily with an aqueous solution having substantially the same composition as the average canine urine shown in Table 1. After six months, the state of corrosion was evaluated based on the appearance of corrosion and any pitting. The tested materials and their test results are shown in Table 2. The steel c...

Embodiment 2

[0037] Under the conditions described in JIS H 8641, a galvanized steel pipe with an outer diameter of 43 mm, a length of 100 mm, and a thickness of 3.5 mm is coated with an epoxy resin coating cured at room temperature on the outer surface. , 30% by weight of bulk paint (titanium oxide), about 2% by weight of other additives and a solution of 6% by weight of solvent, and polymerized by 13% by weight of curing agent, to which the percentage by weight relative to the paint shown in Table 3 The indicated pigments are added to form a coating consisting of anti-corrosion materials. Here, in order to measure the ability of various paints to neutralize ammonium, 100 g of an aqueous solution containing 5% of ammonium ions was prepared, and 1% was added to the powdered paints in the table, and the amount at which the pH value decreased by 1 or more was regarded as is the ability to neutralize ammonium ions. In addition, regarding the type of curing agent, a curing agent using an isoc...

Embodiment 3

[0042] Galvanize a steel pipe with an inner diameter of 150mm, a thickness of 6mm, and a length of 3m by the method described in JIS H 8641, and cover the range of 500mm from the bottom 500mm of the surface with the anticorrosion material of specification 1 shown in Example 1, Cover with the anti-corrosion material of specification 7 shown in Example 1, or cover with the anti-corrosion material of specification 26 in Example 2, and prepare a steel pipe not covered with anti-corrosion material as a comparative example. These steel pipes were buried in concrete so that they were exposed on the concrete surface at a distance of 750 mm from the bottom end. A 50 mm thick soil was covered on top of them to prepare test samples.

[0043] These test samples were sprayed with a solution having the composition shown in Table 1 once a day. After testing one year later, it was found that the material of the comparative example was corroded, and the part buried in the soil was rusted red ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com