Atmospheric and vacuum distillation unit atmospheric pressure tower top dry point prediction method

A technology of atmospheric and decompression devices and prediction methods, applied in neural learning methods, biological neural network models, etc., to achieve strong adaptability, good technical effects, and accurate sample data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

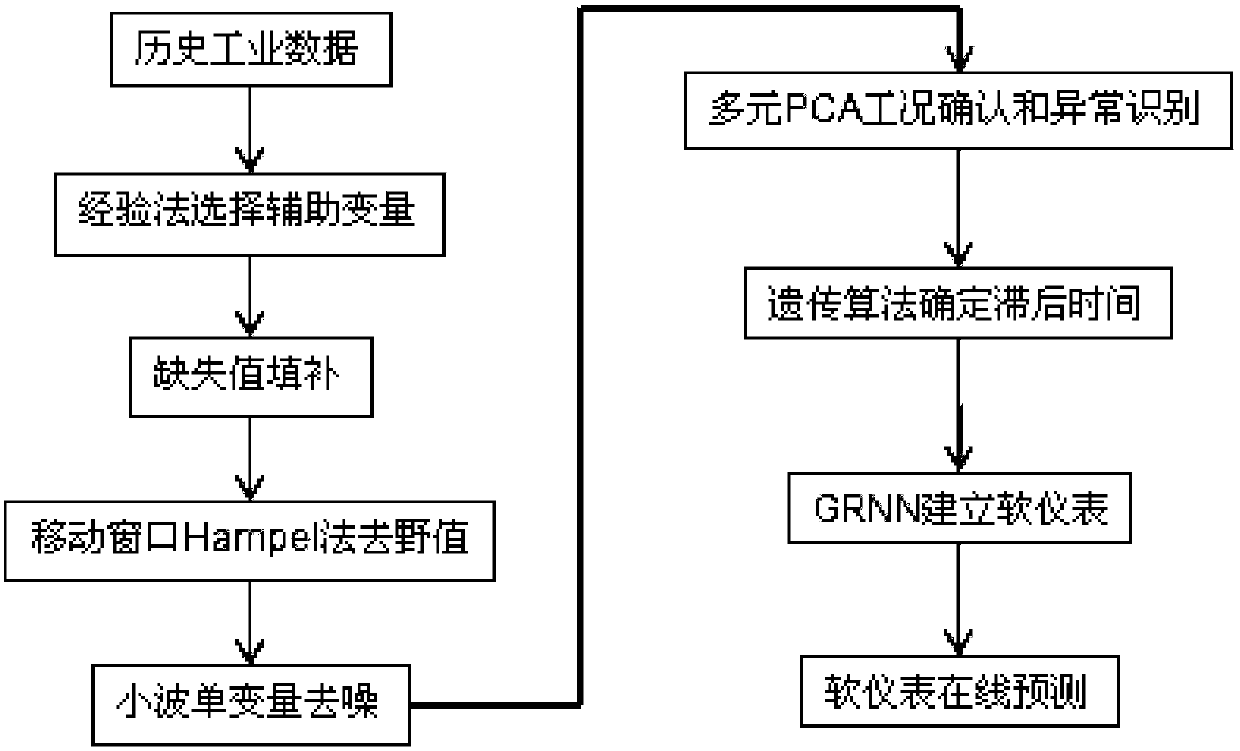

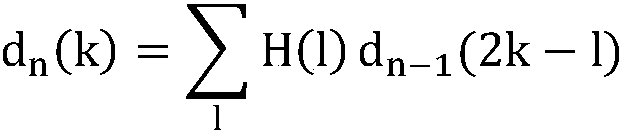

Method used

Image

Examples

Embodiment 1

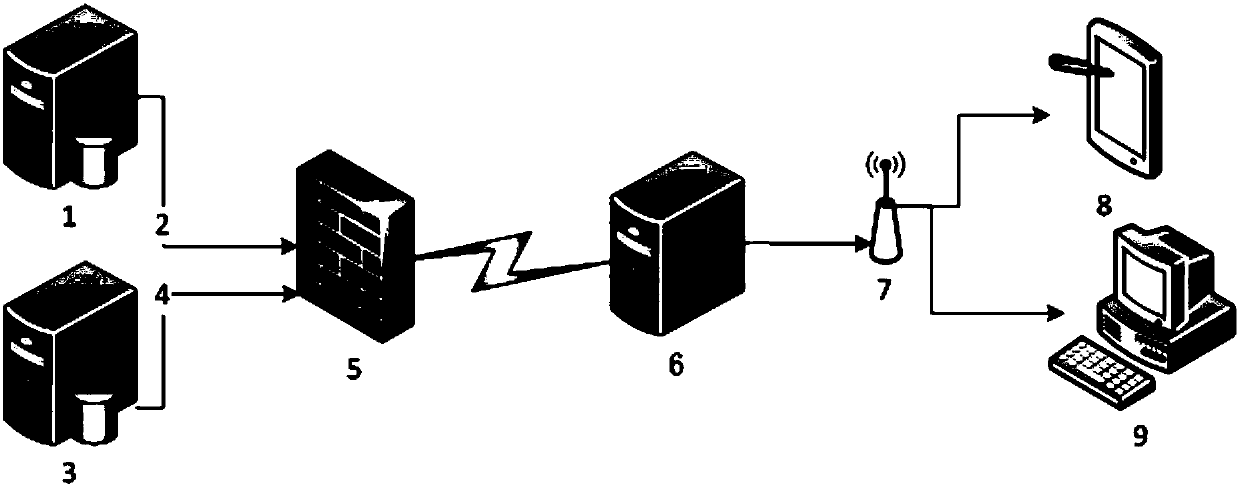

[0065] Adopt the method of the present invention, be used to carry out the prediction of dry point of atmospheric tower top by logging in prediction system; Said prediction system is installed on the server, and server is connected with the server of real-time database system, LIMS system respectively by network cable, and client is Authorized computers and mobile terminals; the working steps of the prediction system are as follows:

[0066] 1) Selected auxiliary variables

[0067] According to the field operator's control experience, consider the relevant auxiliary variables that actually have a greater impact on the dry point at the top of the column, including the feed temperature of the atmospheric column, the return flow rate at the top of the atmospheric pressure, the pressure at the top of the column, the temperature at the top of the column, the amount of steam at the bottom of the column, and the amount of steam at the bottom of the column. Top-to-reflux ratio.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com