Corner fitting for console frame

A technology of consoles and corner fittings, which is applied in the direction of rack/frame structure, electrical components, electrical equipment structural parts, etc., can solve problems such as labor-intensive, bulky consoles, and not meeting the requirements of the times, and improve disassembly Efficiency, the overall structure is stable, and the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

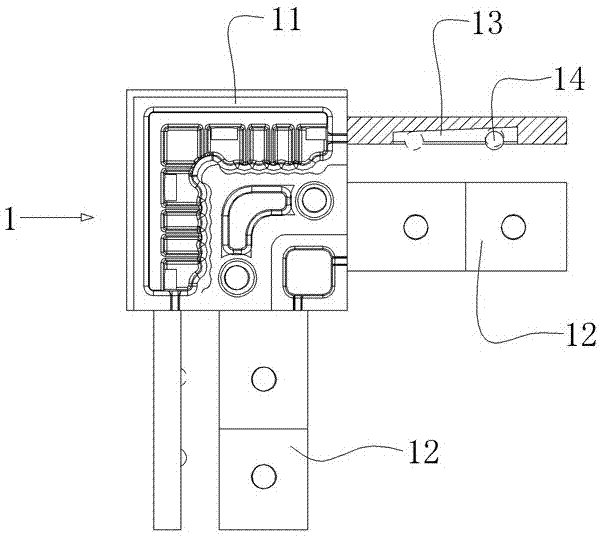

[0013] The console frame of this embodiment uses corner fittings, such as figure 1 and figure 2 As shown, the corner fitting 1 is used for connecting the ends of two adjacent rectangular frames 2 , and the corner fitting 1 includes a block 11 and at least two sets of splints 12 .

[0014] The block body 11 is formed with an end face that abuts against the end of the adjacent frame 2, and each set of splints 12 is composed of an upper splint and a left and right splint that are fixed on one end face of the block body 11 and arranged in the shape of a square. . The block body 11 is a rubber block body, the upper splint and the left and right splints are metal splints, and the corner piece 1 is formed by die-casting the rubber block and the metal splint. Threaded holes are formed on the left and right splints.

[0015] The left and right splints tightly clamp one side of the frame 2 respectively, the upper splint is located at the top of the frame 2 , and a dovetail groove 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com