Efficient stirrer

A stirrer, high-efficiency technology, applied in mixers with rotating stirring devices, chemical instruments and methods, dissolution, etc., can solve the problems that large particles cannot be broken, and the stirring effect needs to be improved, so as to achieve good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

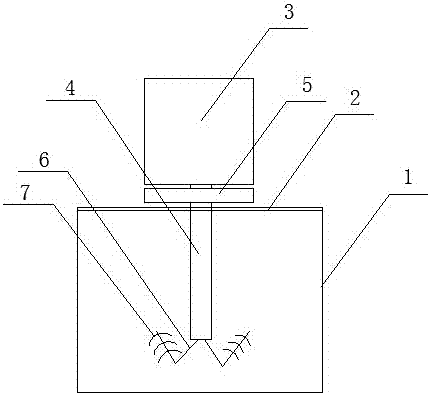

[0014] A high-efficiency stirrer, comprising a shell 1 with an open top, a shell cover 2 covering the top of the shell 1, a motor 3 installed in the center of the shell cover 2, and a stirring shaft 4. One end of the stirring shaft 4 is connected to the motor 3 through a transmission 5 The power output shaft is connected, and the other end extends into the housing 1 through the center of the housing cover 2; the bottom end of the stirring shaft 4 protruding into the housing 1 is provided with a W-shaped stirring piece 6, and the W-shaped stirring piece 6 is symmetrically arranged on the stirring On the shaft 4 , several stirring blades 7 are arranged on the W-shaped stirring blade 6 , and the several stirring blades 7 are symmetrically arranged on both sides of the W-shaped stirring blade 6 . The W-shaped stirring piece 6 is welded to the stirring shaft 4 . The shape of the stirring blade 7 is arc. The distance between the W-shaped stirring plate 6 and the bottom wall of the ...

Embodiment 2

[0016] A high-efficiency stirrer, comprising a shell 1 with an open top, a shell cover 2 covering the top of the shell 1, a motor 3 installed in the center of the shell cover 2, and a stirring shaft 4. One end of the stirring shaft 4 is connected to the motor 3 through a transmission 5 The power output shaft is connected, and the other end extends into the housing 1 through the center of the housing cover 2; the bottom end of the stirring shaft 4 protruding into the housing 1 is provided with a W-shaped stirring piece 6, and the W-shaped stirring piece 6 is symmetrically arranged on the stirring On the shaft 4 , several stirring blades 7 are arranged on the W-shaped stirring blade 6 , and the several stirring blades 7 are symmetrically arranged on both sides of the W-shaped stirring blade 6 . The W-shaped stirring piece 6 is threadedly connected with the stirring shaft 4 . The shape of the stirring blade 7 is arc. The distance between the W-shaped stirring piece 6 and the bot...

Embodiment 3

[0018] A high-efficiency stirrer, comprising a shell 1 with an open top, a shell cover 2 covering the top of the shell 1, a motor 3 installed in the center of the shell cover 2, and a stirring shaft 4. One end of the stirring shaft 4 is connected to the motor 3 through a transmission 5 The power output shaft is connected, and the other end extends into the housing 1 through the center of the housing cover 2; the bottom end of the stirring shaft 4 protruding into the housing 1 is provided with a W-shaped stirring piece 6, and the W-shaped stirring piece 6 is symmetrically arranged on the stirring On the shaft 4 , several stirring blades 7 are arranged on the W-shaped stirring blade 6 , and the several stirring blades 7 are symmetrically arranged on both sides of the W-shaped stirring blade 6 . The W-shaped stirring piece 6 is welded to the stirring shaft 4 . The shape of the stirring blade 7 is arc. The distance between the W-shaped stirring plate 6 and the bottom wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com