Flexible clamping finger provided with microchannels

A micro-pipe and finger technology, applied in chucks, manipulators, manufacturing tools, etc., can solve problems such as poor flexibility and physical damage, and achieve the effect of ensuring stability and realizing automatic adaptation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

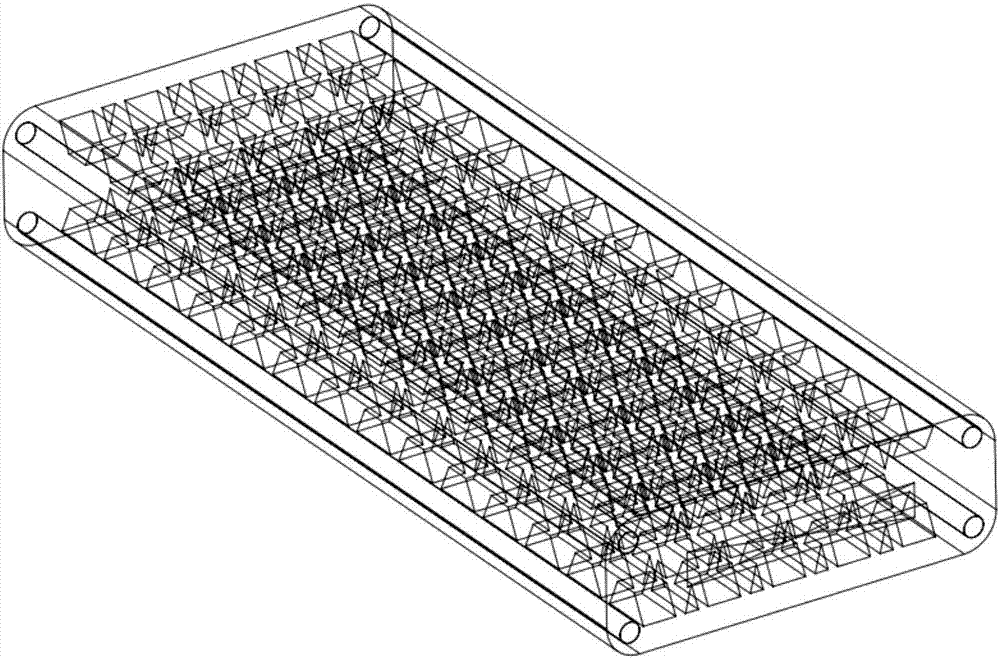

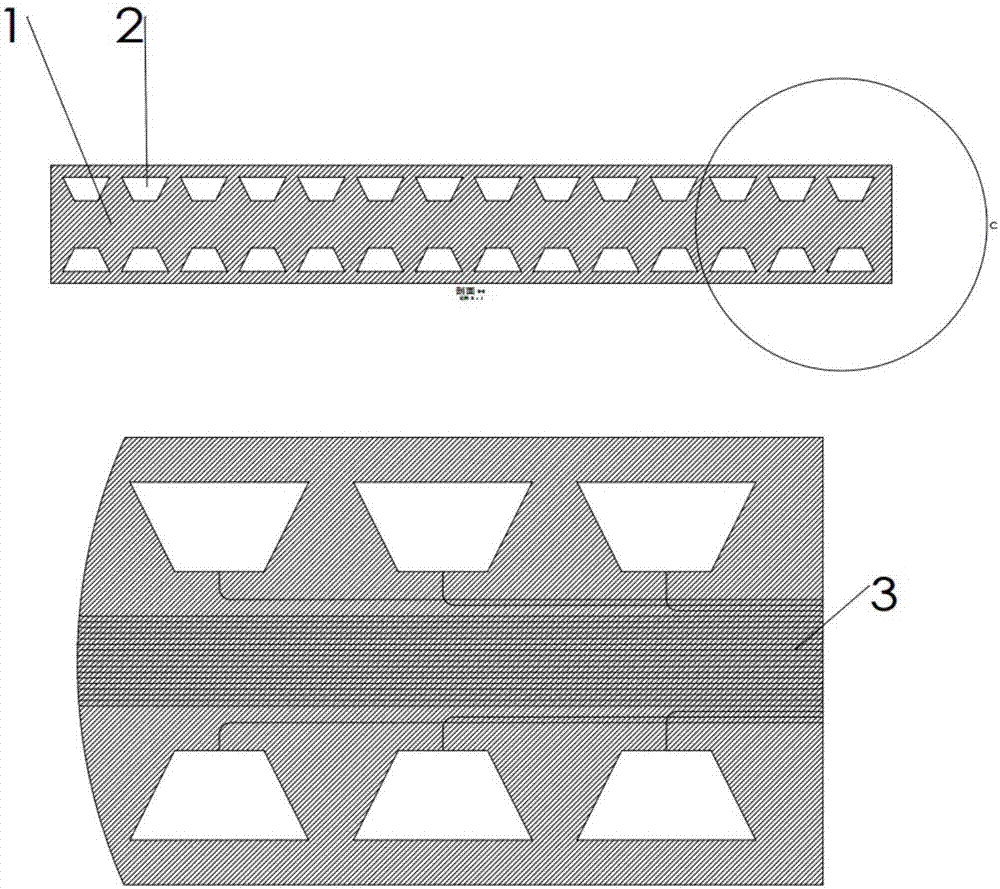

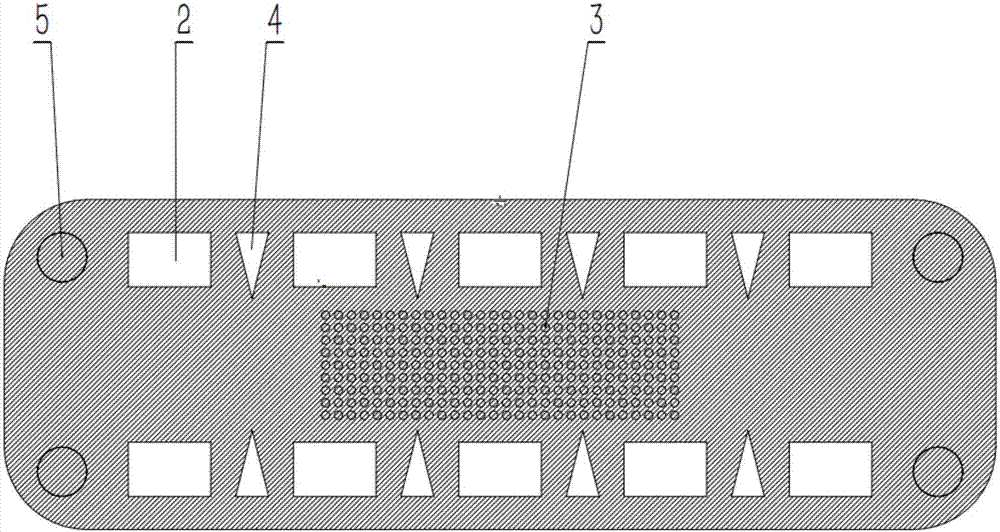

[0029] refer to Figure 1 to Figure 8 , a soft clamping finger of a microchannel, including an elastic finger part for adapting to the shape of the clamped part and providing clamping force through self-deformation and a microfluidic control part for controlling the pressure of the air chamber in the elastic finger, said The elastic finger part includes a finger body and a shaping bar 5, the finger body is a body made of elastic material, the finger body is a cuboid, and the shaping bar 5 is longitudinally arranged on both sides of the finger body, each side A shaping bar 5 is respectively arranged up and down; the middle part of the finger body is arranged with an air chamber, and the air chamber includes a straight quadrangular prism air chamber 2 and a straight triangular prism air chamber 4. Seen from a transverse section, the air chamber is up and down. Symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com