Preparation method of hook face light-transmitting concrete

A light-transmitting concrete and concrete technology, which is applied in the direction of manufacturing tools and ceramic molding machines, can solve the problems of single shape and form of expression, and achieve the effect of simple preparation, rich application fields and scope, and changeable shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

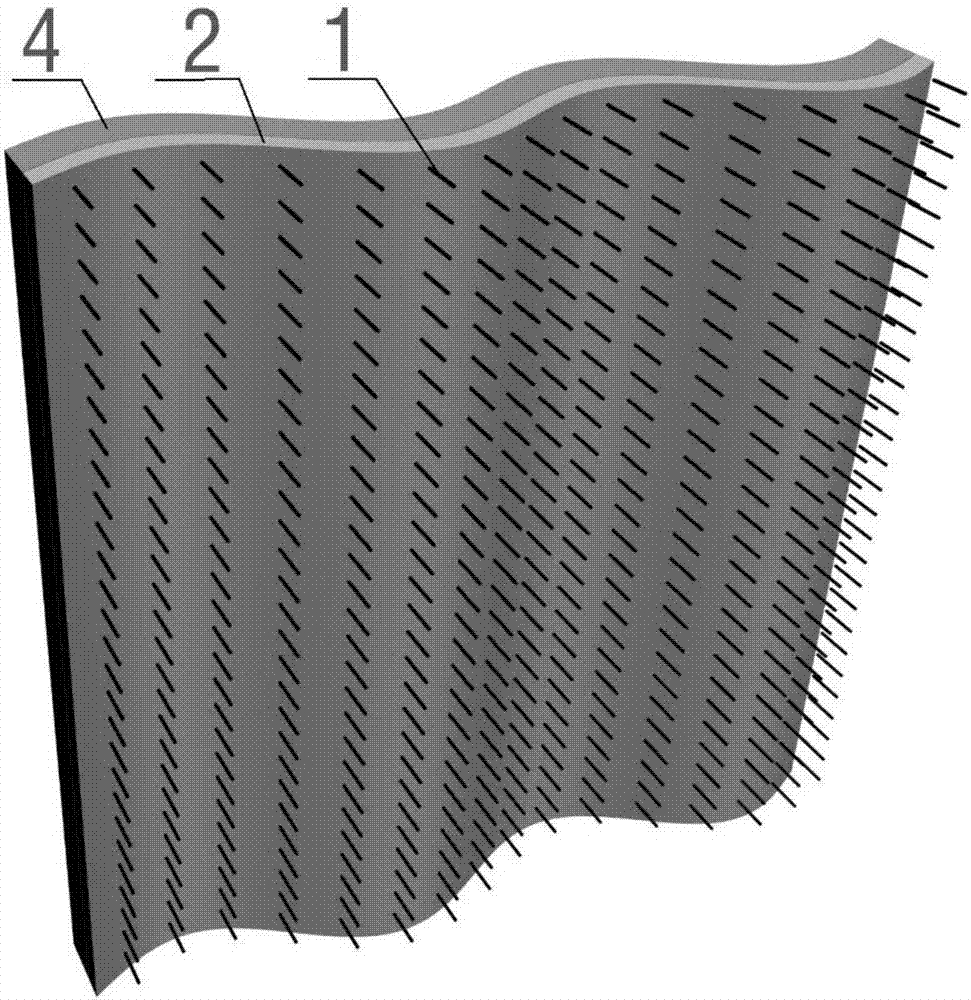

[0032] Such as figure 1 As shown, a preparation method of curved surface light-transmitting concrete comprises the following steps:

[0033] 1) Material preparation:

[0034] Prepare light guide material 1, fixing material 2, concrete paste and curved formwork 4;

[0035] The light guide material is a plurality of plexiglass rods with a diameter of 5mm;

[0036] The fixing material is provided with holes for the light guide material to pass through, and the hole spacing is 10mm;

[0037] The surface template is a wave shape;

[0038] 2) Arrangement of light guide material

[0039] Pass the end of each light guide material through the hole of the fixing material in turn, glue and fix it with glue, and then glue and fix the fixing material on the curved surface template;

[0040] 3) Pouring of concrete:

[0041] Spray the concrete slurry onto the fixed material on which the light guide material has been fixed until the light guide material is completely covered;

[0042] ...

Embodiment 2

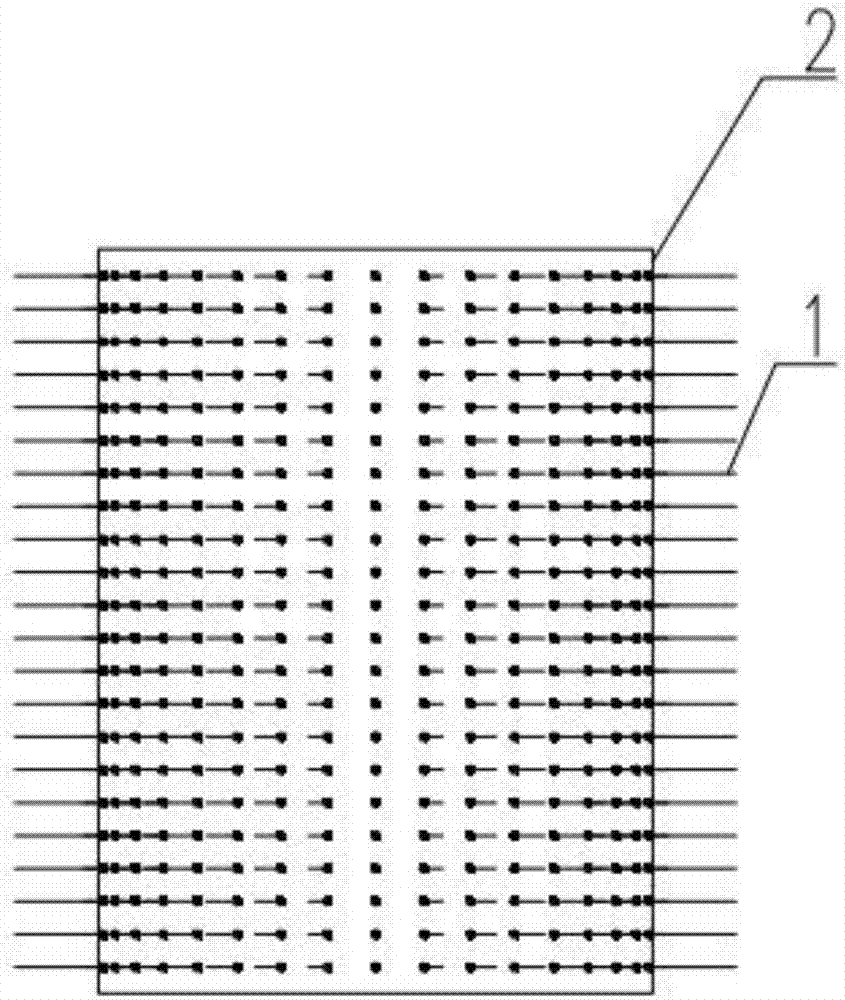

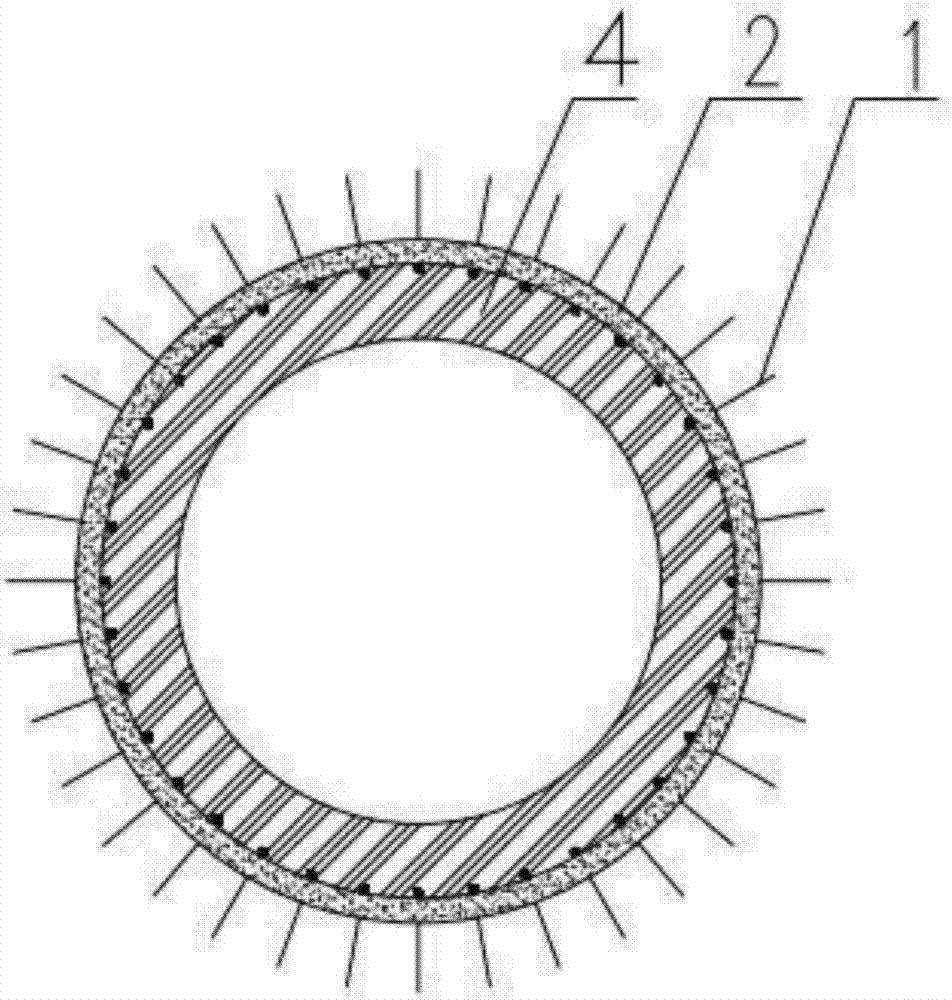

[0048] Such as figure 2 , image 3 As shown, a preparation method of curved surface light-transmitting concrete comprises the following steps:

[0049] 1) Material preparation:

[0050] Prepare light guide material 1, fixing material 2, concrete paste and curved formwork 4;

[0051] The light guide material is a plurality of polymer optical fibers with a diameter of 1mm;

[0052] The fixing material is provided with holes for the light guide material to pass through, and the hole spacing is 4mm;

[0053] The curved surface template is a cylindrical curved surface template;

[0054] 2) Arrangement of light guide material

[0055] Pass the end of each light guide material through the hole of the fixing material in turn, glue and fix it, and then glue and fix the fixing material on the curved template to form a complete cylindrical shape;

[0056] 3) Pouring of concrete:

[0057] Spray the concrete slurry onto the fixed material on which the light guide material has been ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com