Ultra-low friction coefficient self-lubricating coating and preparation method thereof

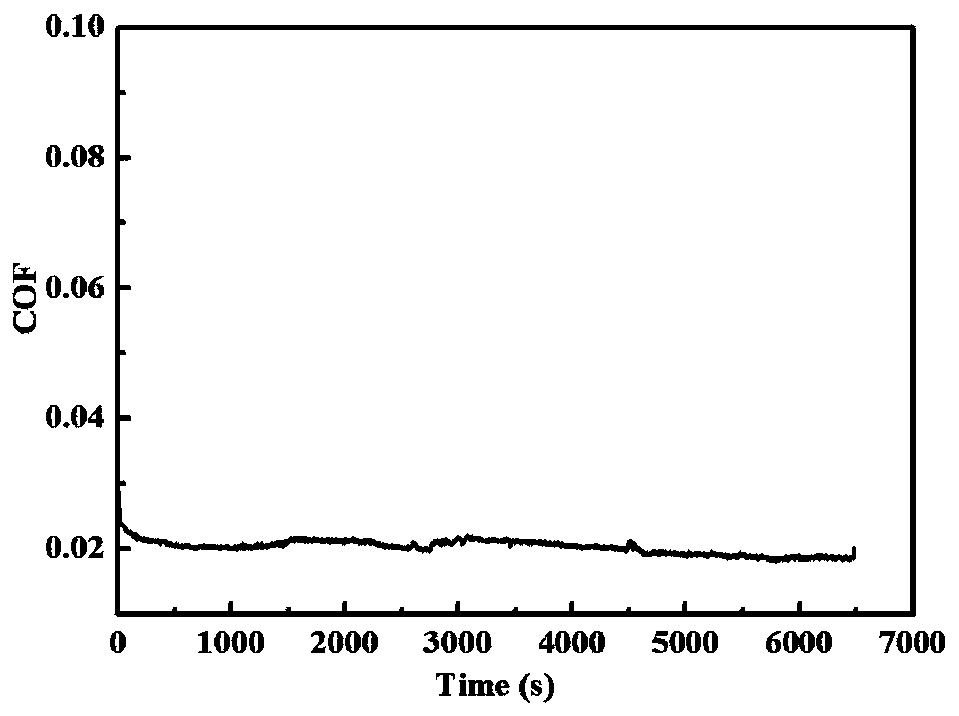

A self-lubricating coating, ultra-low friction technology, used in coatings, microsphere preparation, microcapsule preparations, etc., can solve problems such as poor lubrication performance and high wear rate, improve lubrication performance, broaden application fields, avoid The effect of the ploughing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

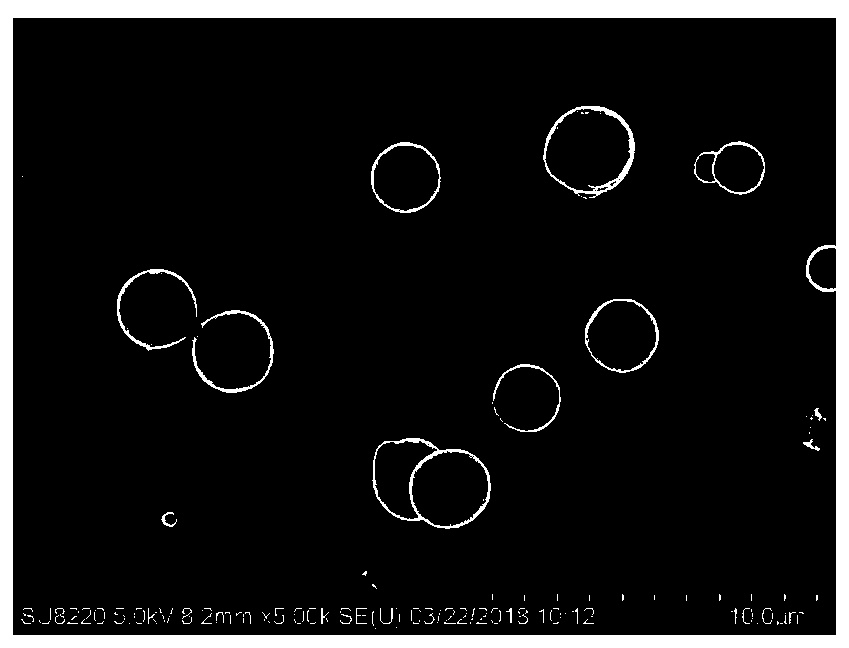

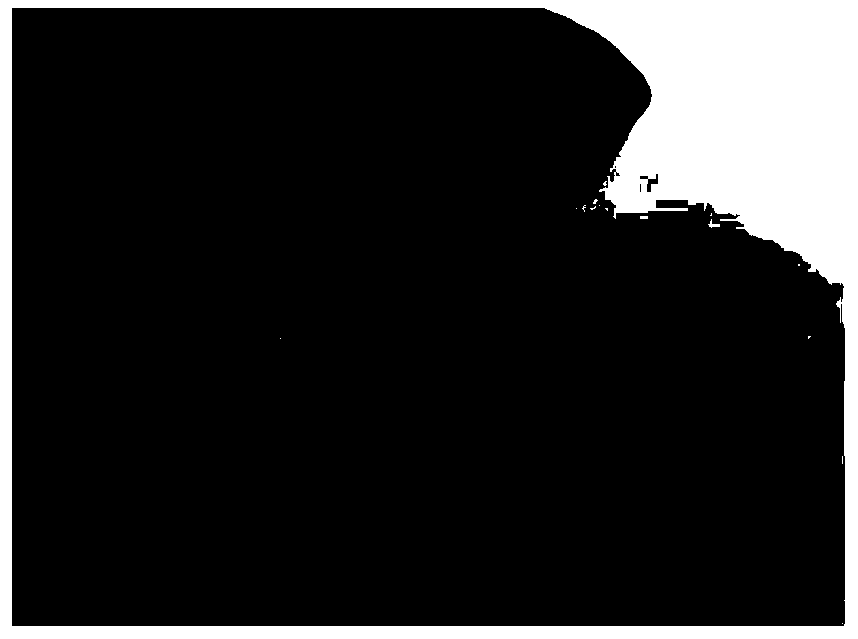

[0036] (1) Microcapsules whose core material is polyalphaolefin (abbreviation: PAO6) and wall material is polystyrene (abbreviation: PS) are prepared by solvent evaporation method.

[0037] 4g PAO6 and 2g PS were added to 40mL of dichloromethane solvent and mixed, magnetically stirred evenly to obtain solution A, the mass fraction of dichloromethane in solution A was 89.83%, and the mass percentage of lubricant and polymer was 1:0.5. Prepare 200 mL of a mixed aqueous solution B of gelatin and polyvinyl alcohol, wherein the mass fraction of gelatin is 0.2%, and the mass fraction of polyvinyl alcohol is 0.5%. Under the condition of mechanical stirring at 600rpm, the above-mentioned solution A was added to solution B at one time to form a microemulsion. The mass percentage of solution A and solution B in the microemulsion was 1:4, and the microemulsion was reacted at 45°C for 4h to completely dichloromethane Volatilize, collect after filtration, rinse repeatedly with deionized wa...

Embodiment 2

[0043] (1) Nanocapsules with core material of linseed oil and wall materials of PS and polyvinyl acetate were prepared by solvent evaporation method.

[0044] Add 6g linseed oil, 2g PS, and 0.5g polyvinyl acetate into 60mL of chloroform and mix, magnetically stir to obtain solution A evenly, the mass fraction of chloroform in solution A is 91.37%, the mass fraction of lubricant and polymer The percentage is 1:1.42. Prepare 200 mL of polyvinyl alcohol aqueous solution B with a mass fraction of 0.5%. Under the condition of mechanical stirring at 800rpm, the above-mentioned solution A was added to solution B at one time to form a microemulsion. The mass percentage of solution A and solution B in the microemulsion was 1:3, and the microemulsion was reacted at 45°C for 4h to make the chloroform Volatilize, collect after filtration, rinse repeatedly with deionized water, and dry at 25°C for 24 hours to obtain nanocapsules containing linseed oil. The prepared nanocapsules were char...

Embodiment 3

[0050] (1) Microcapsules whose core material is synthetic lubricating oil (abbreviation: SNOw-20) and wall material is PS are prepared by solvent evaporation method.

[0051] Add 2g SNOw-20 and 2g PS to 50mL of dichloromethane solvent and mix, magnetically stir to obtain solution A evenly, the mass fraction of dichloromethane in solution A is 94.31%, the mass percentage of lubricant and polymer is 1:1 . Prepare 200 mL of a mixed aqueous solution B of Tween 80 and gum arabic, wherein the mass fraction of Tween 80 is 1%, and the mass fraction of gum arabic is 0.1%. Under the condition of mechanical stirring at 700rpm, the above-mentioned solution A was added to solution B at one time to form a microemulsion. The mass percentage of solution A and solution B in the microemulsion was 1:4, and the microemulsion was reacted at 35°C for 4h to completely Volatilize, collect after filtration, rinse repeatedly with deionized water, and dry at 25°C for 24 hours to obtain PS microcapsules...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com