Door lock equipped with pull-push handle

A handle and door lock technology, applied in handle connection, door/window accessories, construction, etc., can solve the problems of inability to change the direction of the door lock and the action direction of the latch, inconvenient to open the door, and inconvenient for users to open the door, etc. Excellent performance and convenience of setting, the effect of a wide range of settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

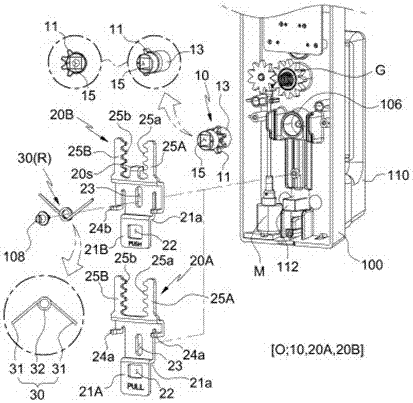

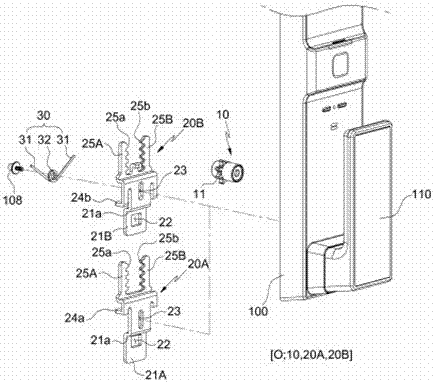

[0059] The present invention can be modified variously and has various forms, and the present invention will describe aspects (or embodiments) in detail in the text. However, this is not intended to limit the present invention to a specific disclosed form, and it should be understood that the present invention includes all changes, equivalents, and substitutions included within the spirit and technical scope of the present invention.

[0060] In the various drawings, the same reference numerals, especially the tens digit and one digit or the same reference numerals for ten digits, one digit and Roman letters, indicate the same or components with similar functions, unless otherwise specified Note that components denoted by reference numerals in the drawings may be regarded as components conforming to this standard.

[0061] In addition, in consideration of convenience of understanding, etc., in each drawing, the size and thickness of constituent elements are exaggerated, shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com