Vehicle-mounted screen rotating structure

A technology of screen rotation and screen, applied in vehicle parts, transportation and packaging, etc., can solve the problems of inconvenient processing and molding, inconvenient installation, complex structure, etc., and achieve the effect of convenient processing, convenient disassembly and assembly, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

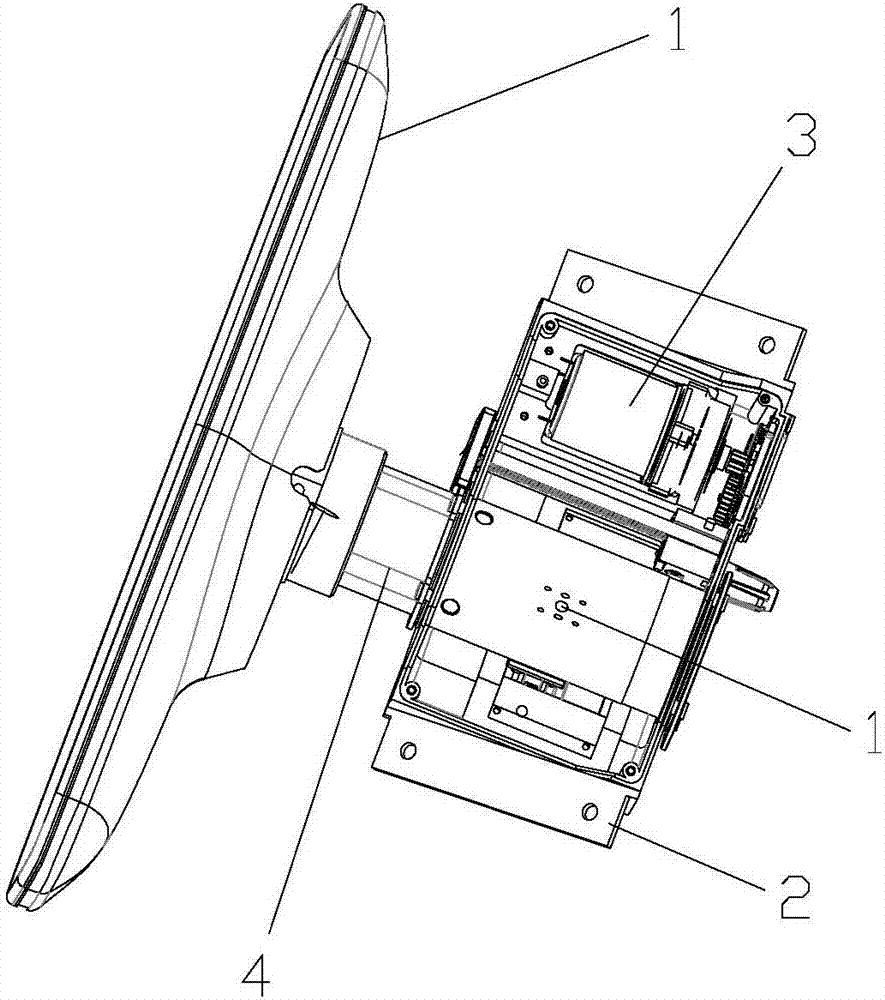

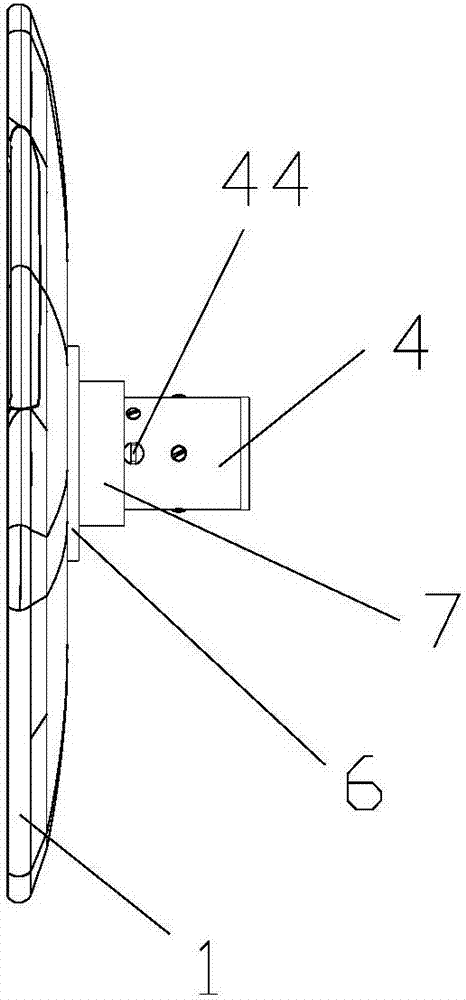

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, this embodiment discloses a vehicle-mounted screen rotation structure, including a screen 1, a base 2, a driving motor 3, a rotating shaft 4, and a transmission shaft 5; the driving motor 3 and the rotating shaft 4 are respectively arranged on the base 2; the transmission shaft 5 The rotating shaft 4 is driven to rotate by the drive motor 3; an L-shaped slot 41 is provided on the outer surface of the rotating shaft 4; a screen pressing block 42 is arranged in the rotating shaft 4; an energy storage part is arranged on the screen pressing block 42 43; A limiting part 44 for pre-pressing the screen pressing block is provided on the rotating shaft 4. The specific limiting part 44 can be a limiting pin, and a hole is opened on the rotating shaft 4 for the limiting pin 4 to be inserted into the rotating shaft 4. Limiting hole, so that the limit pin can be inserted into the inside of the rotating shaft 4 to pre-...

Embodiment 2

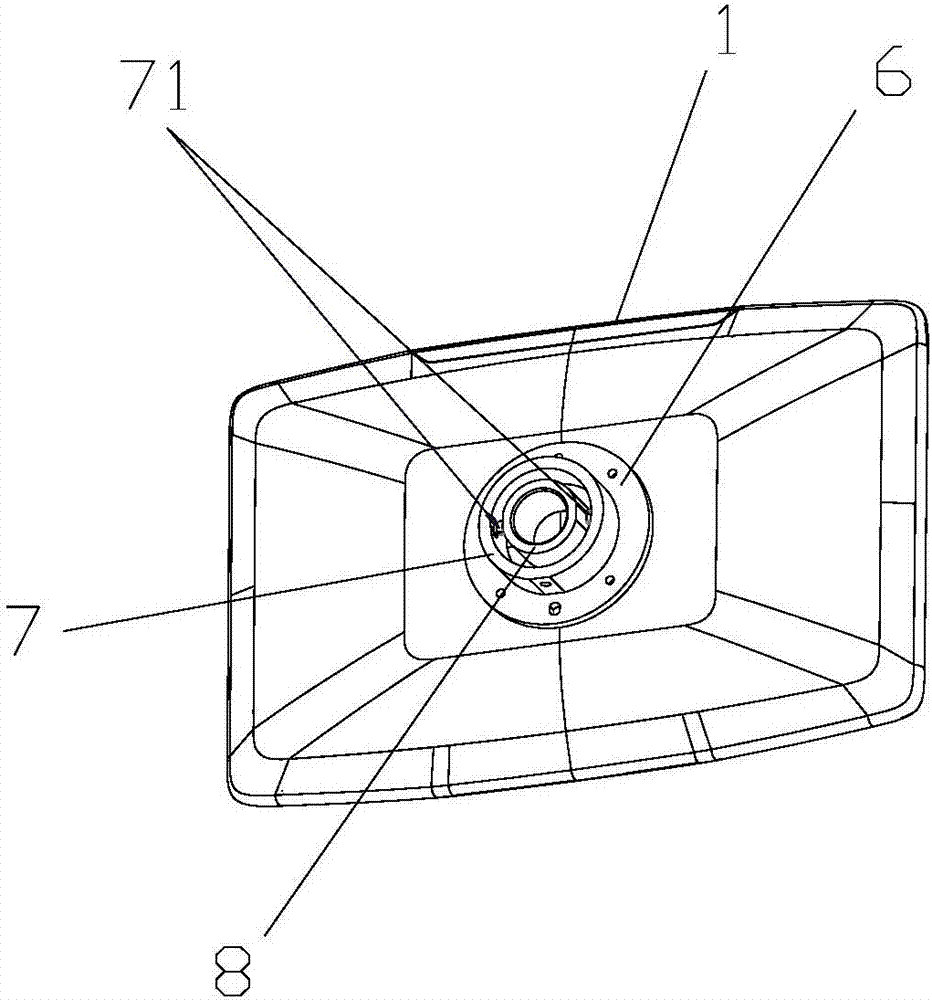

[0030] Such as Figure 5 , Image 6 As shown, as a further technical solution, the difference between this embodiment and Embodiment 1 is that an arc-shaped track groove 45 is also provided on the rotating shaft 4; one end of the transmission shaft 5 is installed on the drive motor 3, and the other end is installed In the arc track groove 45 on the rotating shaft 4 , driven by the driving motor 3 , the rotating shaft 4 is driven to rotate. Simultaneously, a shaft sleeve 9 is sleeved on the transmission shaft 5, and its function is to make the shaft sleeve 9 contact with the arc-shaped track groove 45 on the rotating shaft 4, and drive the rotating shaft 4 to rotate through rolling friction to reduce frictional force.

[0031] Specifically, when designing, the initial end and the terminal end of the arc track groove 45 can use a straight line parallel to the direction of motion of the transmission shaft 5, so as to realize the self-locking of the two positions; meanwhile, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com