Fenofibric acid preparation method

A technology of fenofibric acid and bromoisobutyric acid is applied in the field of preparation of fenofibric acid, which can solve the problems of long reaction time, thick system, burning of stirring paddle motor, etc., and achieve good sample stability and system viscosity. The effect of low consistency and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

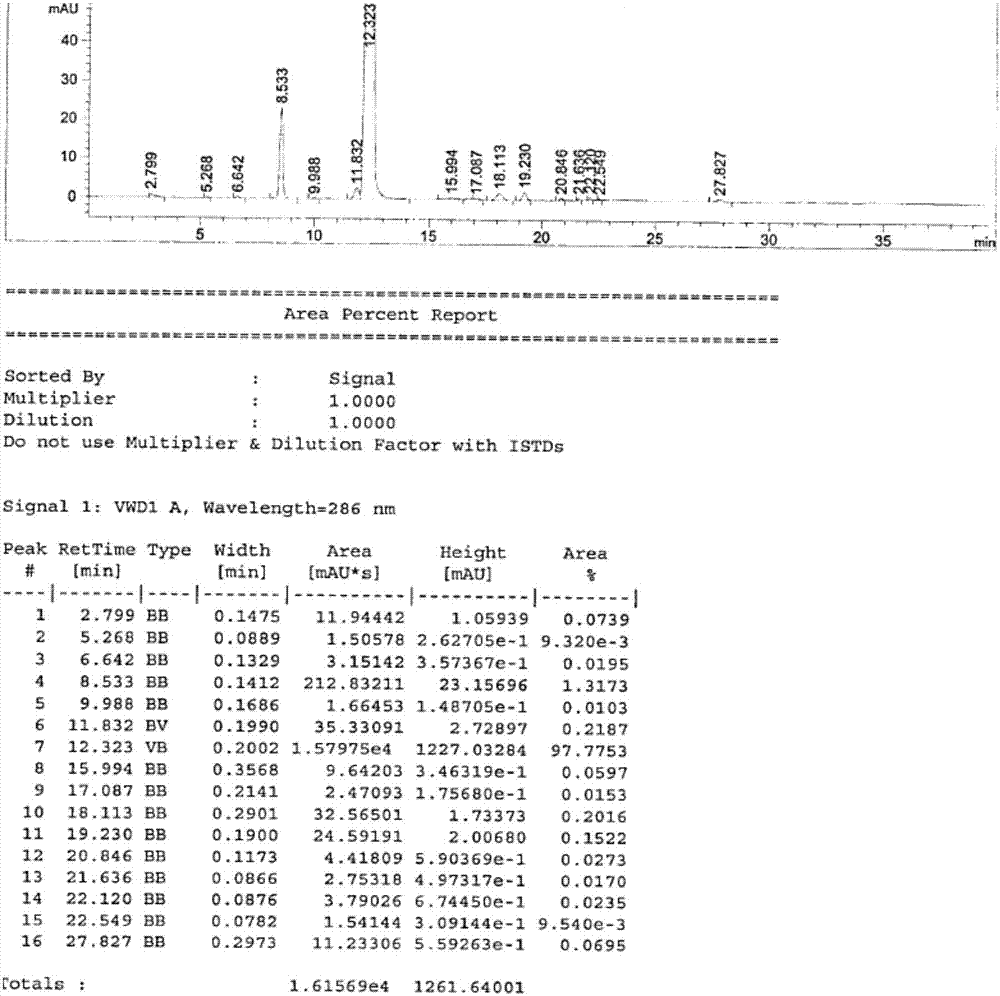

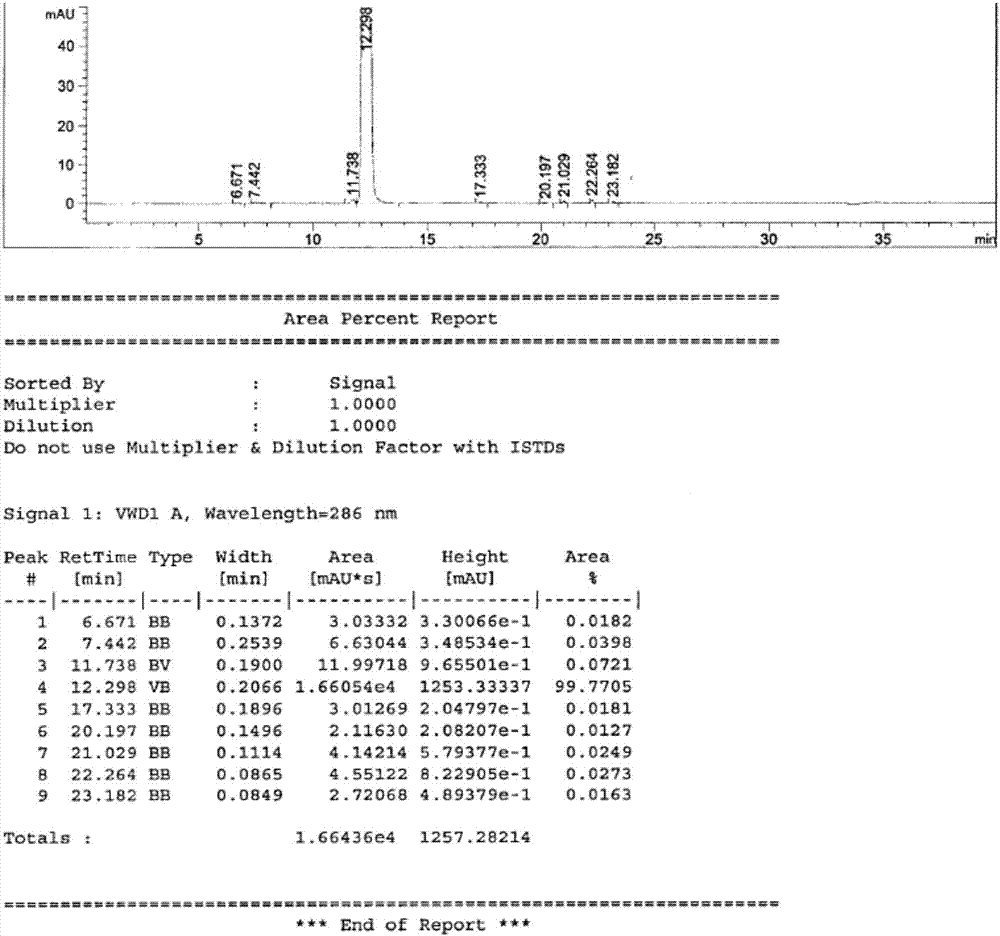

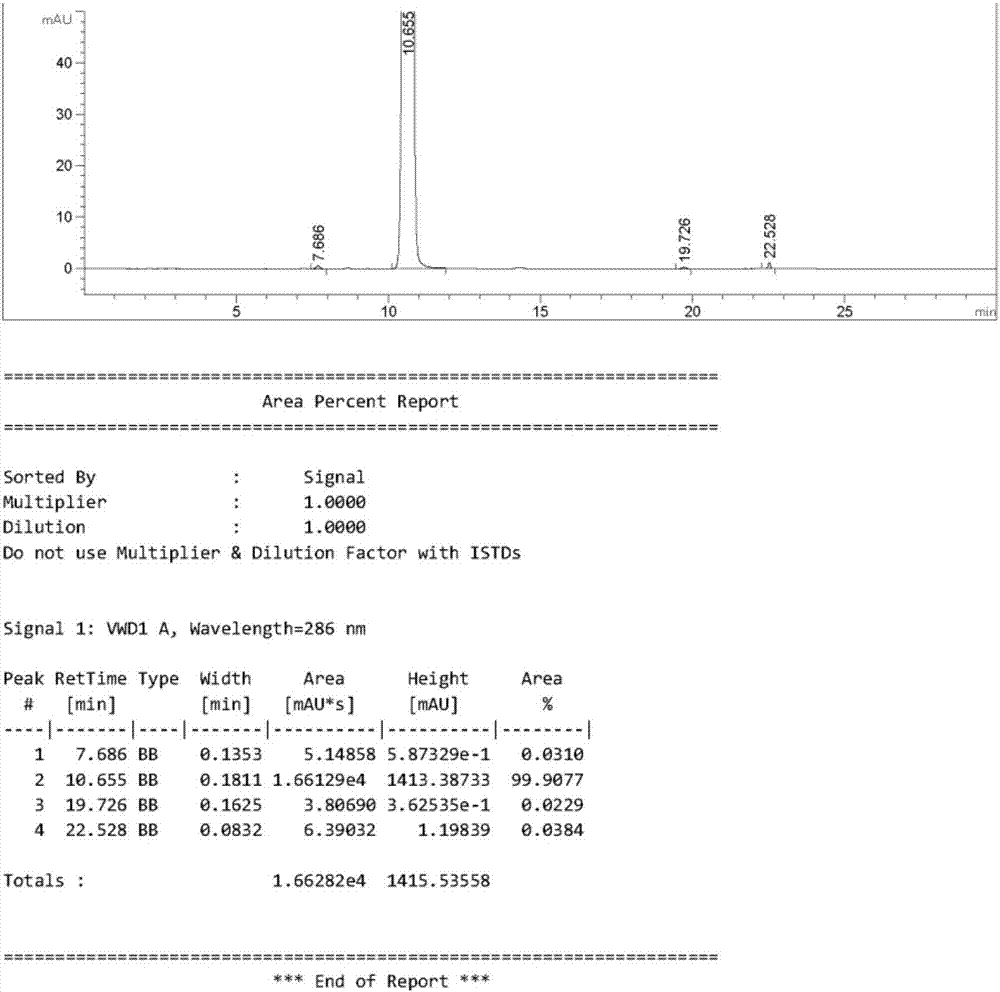

Image

Examples

Embodiment 1a

[0046] Embodiment 1a (synthesis of fenofibric acid)

[0047]Weigh 1kg of 4-chloro-4'-hydroxybenzophenone, add it to a 50L dry reaction kettle, add 12kg methyl ethyl ketone and 0.77kg sodium hydroxide, heat up to 45-60℃ under stirring, stir for 30 minutes, add 0.2 kg of purified water, stirred for 1 hour, kept at 45-60°C, and added dropwise 2-bromoisobutyric acid butanone solution (1kg 2-bromoisobutyric acid dissolved in 3kg butanone) to the kettle, and the reaction was completed 3 to 5 hours.

Embodiment 1b

[0048] Embodiment 1b (synthesis of fenofibric acid)

[0049] Weigh 1kg of 4-chloro-4'-hydroxybenzophenone, add it to a 50L dry reaction kettle, add 12kg methyl ethyl ketone and 0.77kg sodium hydroxide, heat up to 45-60℃ under stirring, stir for 30 minutes, add 0.2 kg of methanol, stirred for 1 hour, kept at 45-60°C, added dropwise 2-bromoisobutyric acid butanone solution (1kg 2-bromoisobutyric acid dissolved in 3kg butanone) to the kettle, after addition, reaction 5 ~6 hours.

Embodiment 1c

[0050] Embodiment 1c (synthesis of fenofibric acid)

[0051] Weigh 1kg of 4-chloro-4'-hydroxybenzophenone, add it to a 50L dry reaction kettle, add 12kg methyl ethyl ketone and 0.77kg sodium hydroxide, heat up to 45-60℃ under stirring, stir for 30 minutes, add 0.2 kg of ethanol, stirred for 1 hour, kept at 45-60°C, added dropwise 2-bromoisobutyric acid butanone solution (1kg 2-bromoisobutyric acid dissolved in 3kg butanone) to the kettle, after addition, reaction 5 ~6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| chromatographic purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap