Construction method of double-wall steel cofferdam divided into blocks

A double-walled steel cofferdam and construction method technology, which is applied in basic structure engineering, construction and other directions, can solve the problems of complex pebble covering layer geology, unrealizable construction plan, difficult foundation pit excavation protection, etc., and achieves strong adjustability. , The effect of reducing the amount of excavation works and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

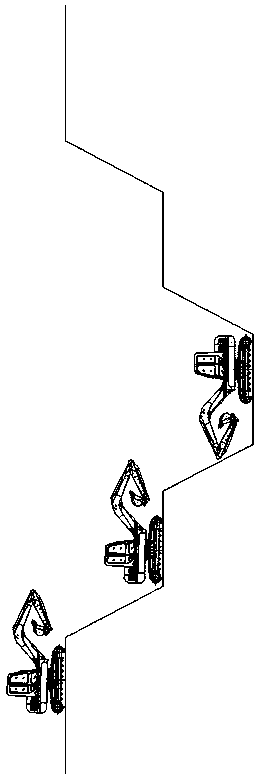

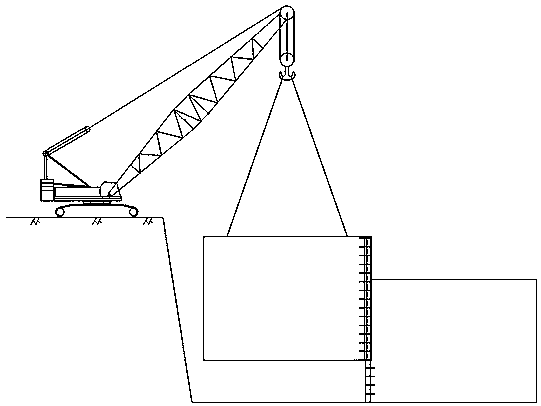

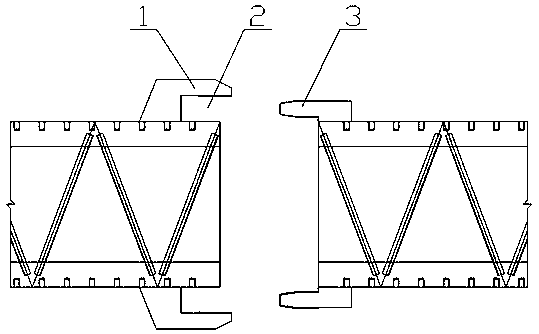

[0014] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. like Figure 1 to Figure 4 Shown: A construction method for double-walled steel cofferdams to be lowered into blocks is carried out according to the following steps: firstly, the construction of island building and filling is carried out, that is, after the site is leveled, measurement and stakeout are carried out to determine the excavation line of the foundation pit, and at the same time, the excavation opening is determined. Personnel, machinery and equipment are in place;

[0015] Then, the steel cofferdam foundation pit is cut and excavated, and the excavation point is determined according to the actual situation of the site and the excavation is started. The excavation depth is strictly controlled in accordance with the designed base elevation, and the excavation length is determined by the length of the first steel cofferdam unit block, which can me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com