A 3D Atlas Method for Studying the Stress Characteristics of Excavator Working Devices

A technology of working devices and graphs, applied in computer-aided design, special data processing applications, instruments, etc., can solve the problems of little research, increase analysis errors, and fail to realize hexahedral grid division of working devices, so as to improve calculation accuracy , the effect of reducing the calculation scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

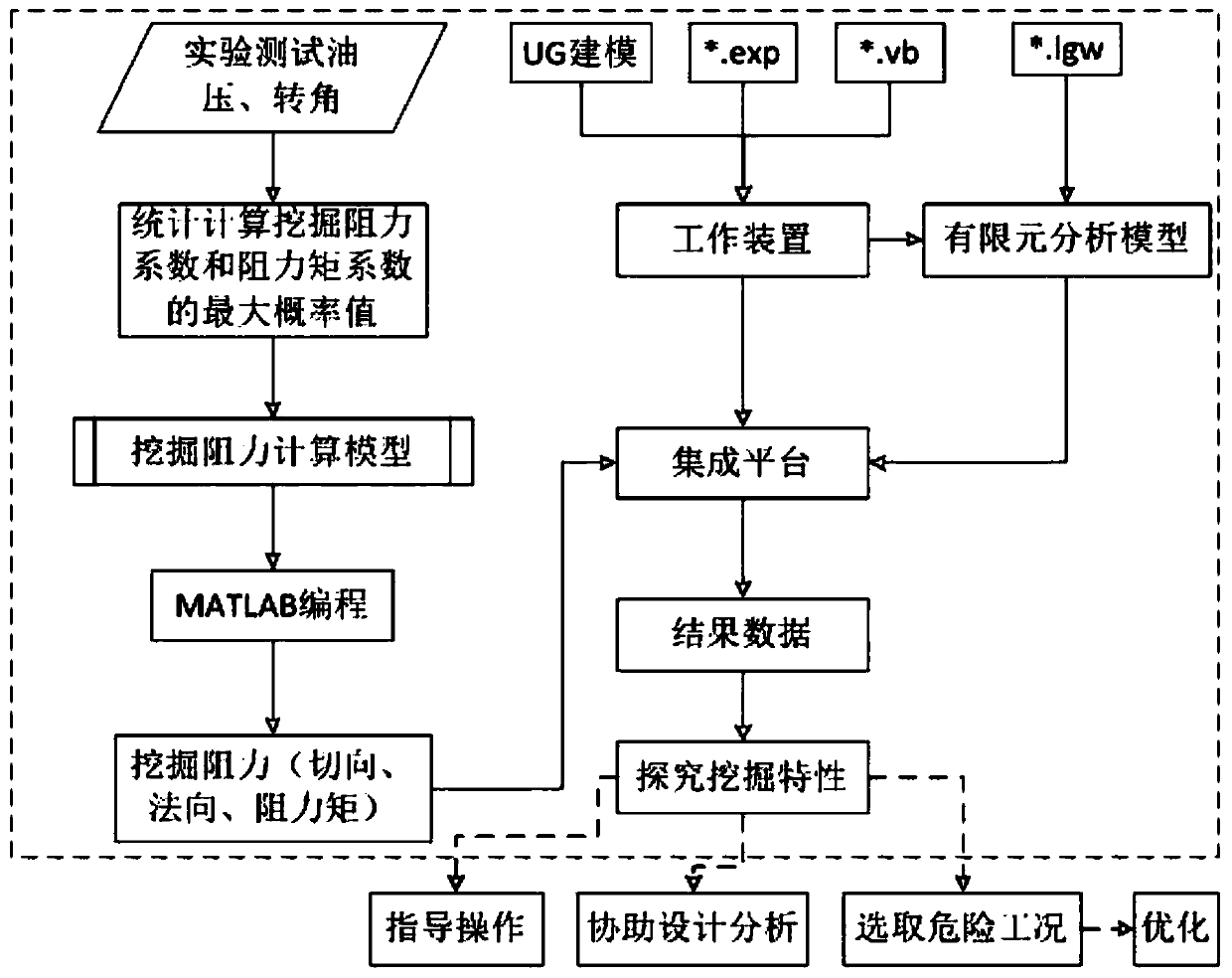

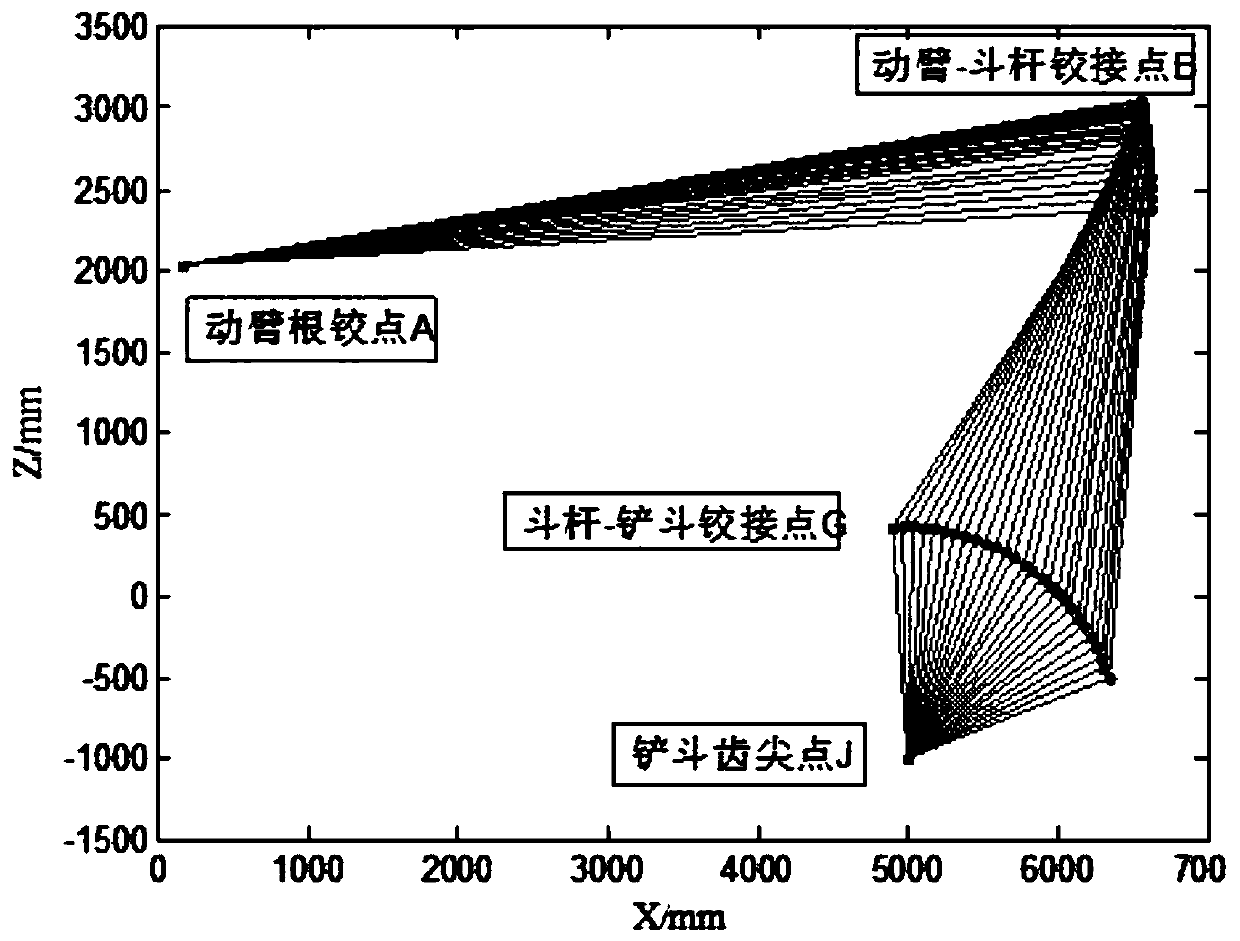

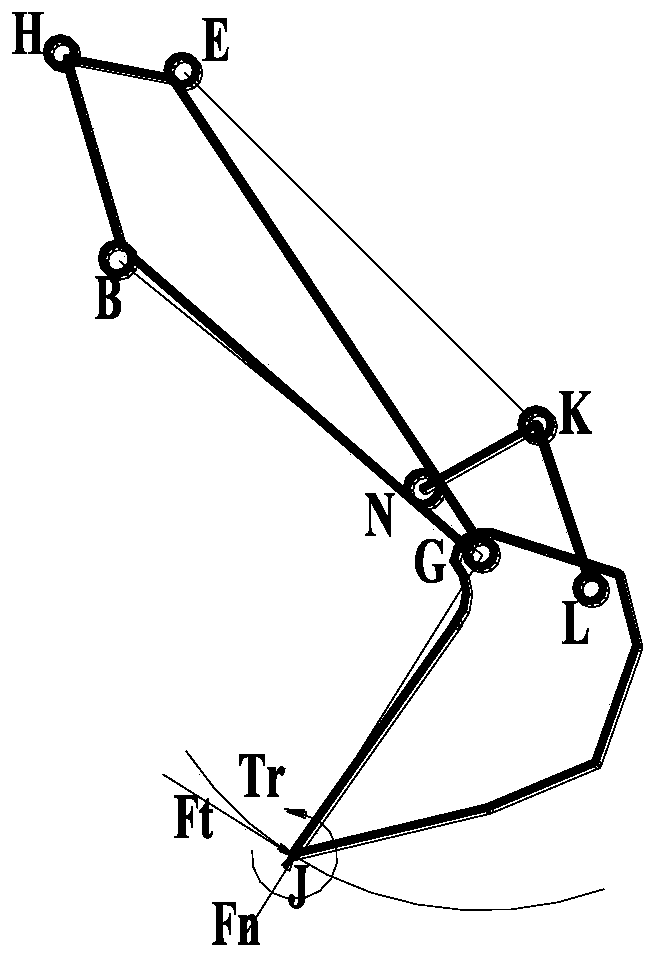

[0059] In this embodiment, a three-dimensional map method for studying the stress characteristics of excavator working devices is proposed in combination with a domestic hydraulic excavator. The specific process is as follows figure 1 As shown, the positive load is considered in the analysis process, assuming that the load on the bucket teeth is evenly distributed along the bucket lip. Specific steps are as follows:

[0060] S1. The real-time oil pressure data of the excavator cylinder and the relative rotation angle data of the boom, arm and bucket were measured; NS-RB angular displacement sensor, NSF pressure sensor and NS-DAC3000 multi-channel data were mainly used in the test Acquisition System. The main parameters are shown in Table 1 and Table 2:

[0061]

[0062] S2. Reversely calculate each simplified force in the excavation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com