Stirring feet including drive shaft driven in rotation by motorized housing

A technology of stirring feet and drive shafts, applied in the field of stirring feet, can solve the problems of inability to change the gap and expensive implementation, and achieve the effect of economical implementation, small positioning and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

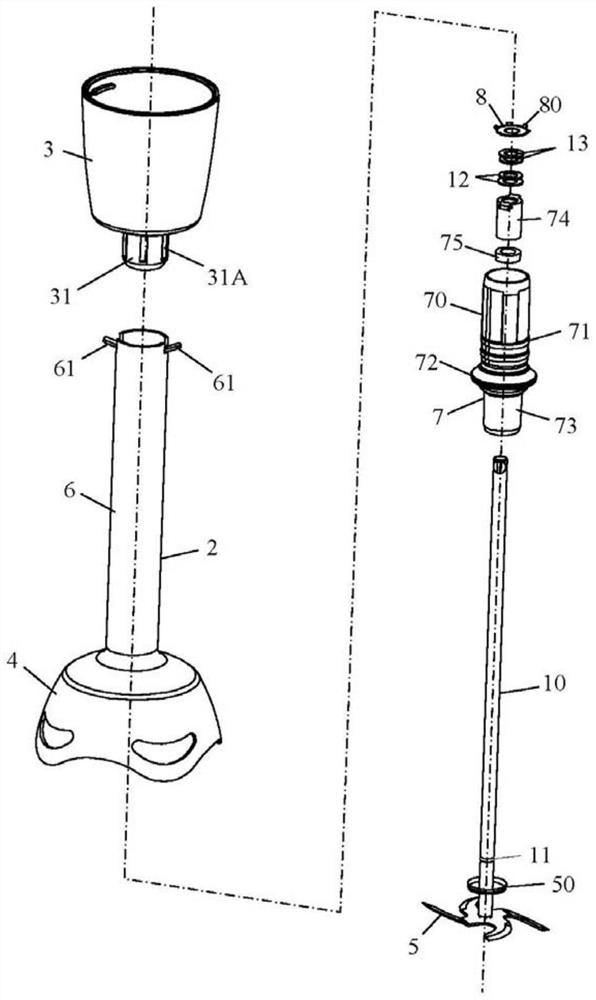

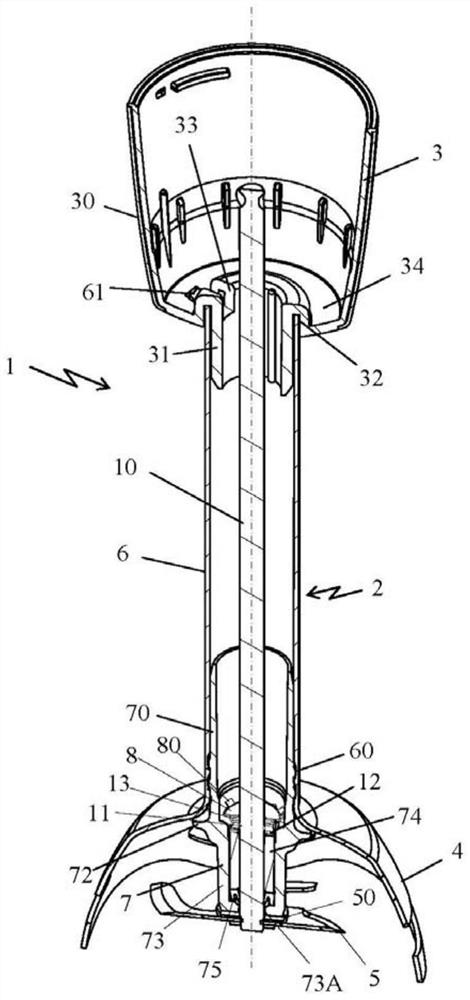

[0038] Only elements necessary for understanding the invention are shown. For the convenience of reading the drawings, the same elements are given the same reference numerals in different drawings.

[0039] And it is worth noting that in this document, the terms "lower", "upper", "higher" and "lower" used to describe the stirring foot refer to when the stirring foot is arranged vertically with its protective cover facing The mixing foot in use when oriented downwards.

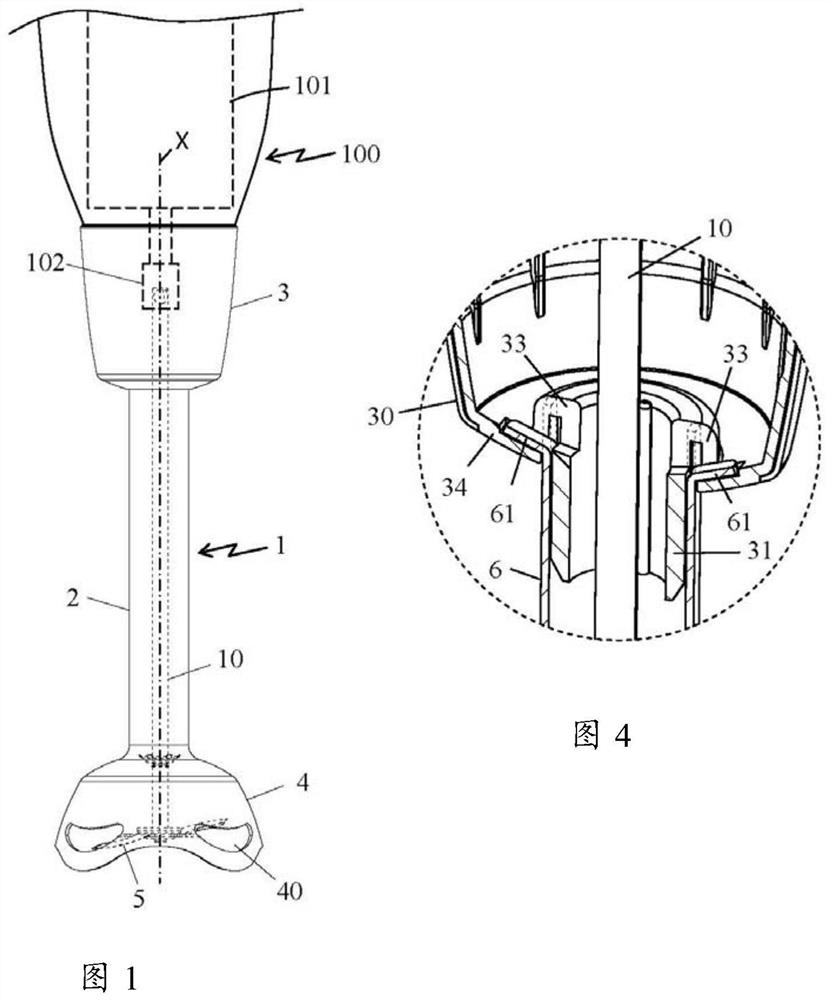

[0040] figure 1 A domestic blender is shown comprising a housing 100 containing a motor 101 schematically indicated by dashed lines and arranged along the longitudinal axis X of the housing, said motor 101 having an output shaft at Its lower end is equipped with a rotary driver 102 protruding to the outside of the housing 100 .

[0041] The household mixer comprises a stirring foot 1, and the stirring foot 1 comprises a tubular column body 2, and the tubular column body 2 comprises an upper end integrally co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap