Method for sorting silicon wafers according to their bulk lifetime

A bulk lifetime, wafer technology, applied in crystal growth, chemical instruments and methods, sorting, etc., can solve problems such as inability to optimally optimize homojunction cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Single crystal silicon ingots obtained by the Czochralski (CZ) method contain a large number of thermal donors because the silicon has a high concentration of interstitial oxygen and cools slowly. These thermal donors are then found in silicon wafers originating from cut ingots.

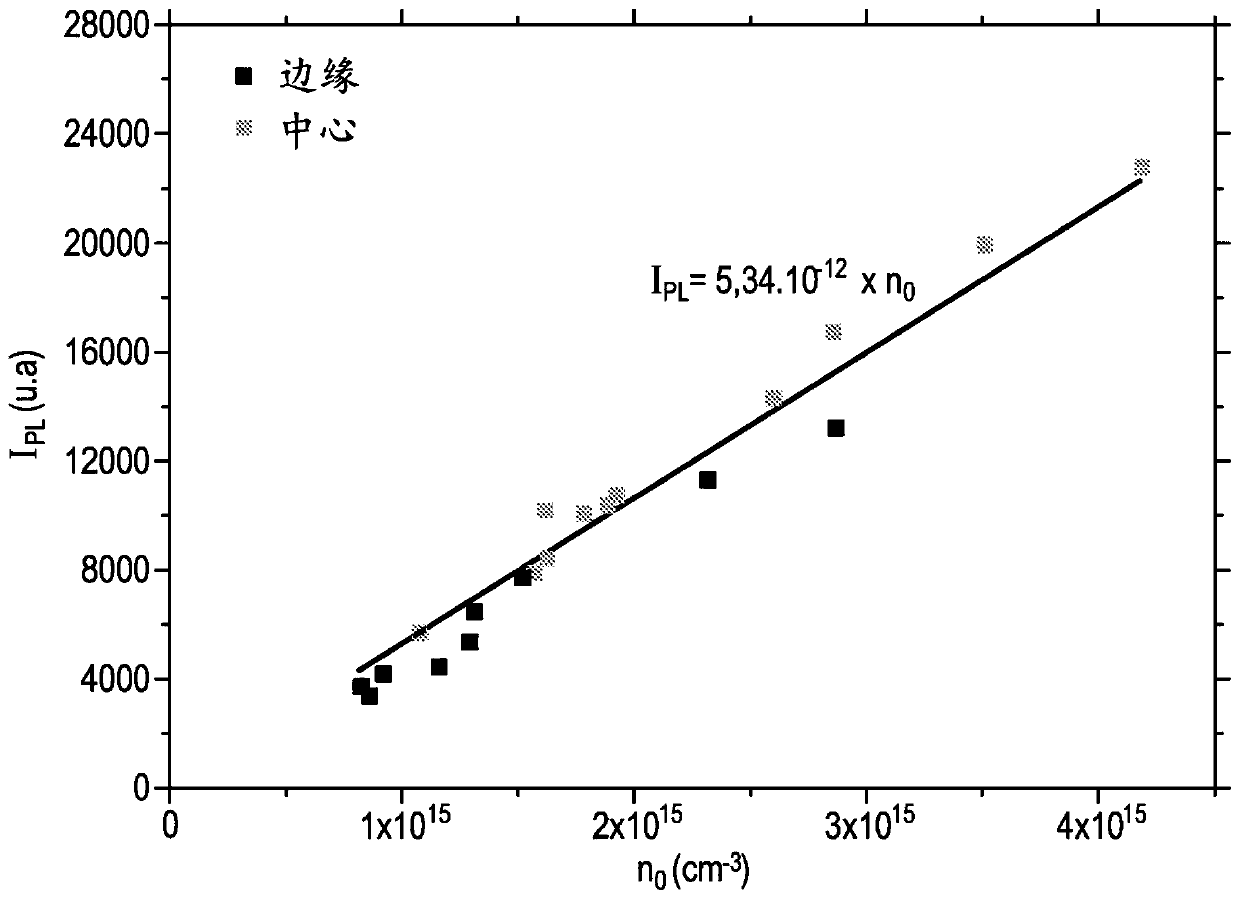

[0061] Thermal donors have two effects on the properties of silicon. First, they affect the majority free charge carrier concentration, often referred to as net doping, since each thermal donor generates two free electrons. Second, certain thermal donors act as recombination centers for electron-hole pairs, which limits the bulk lifetime of charge carriers.

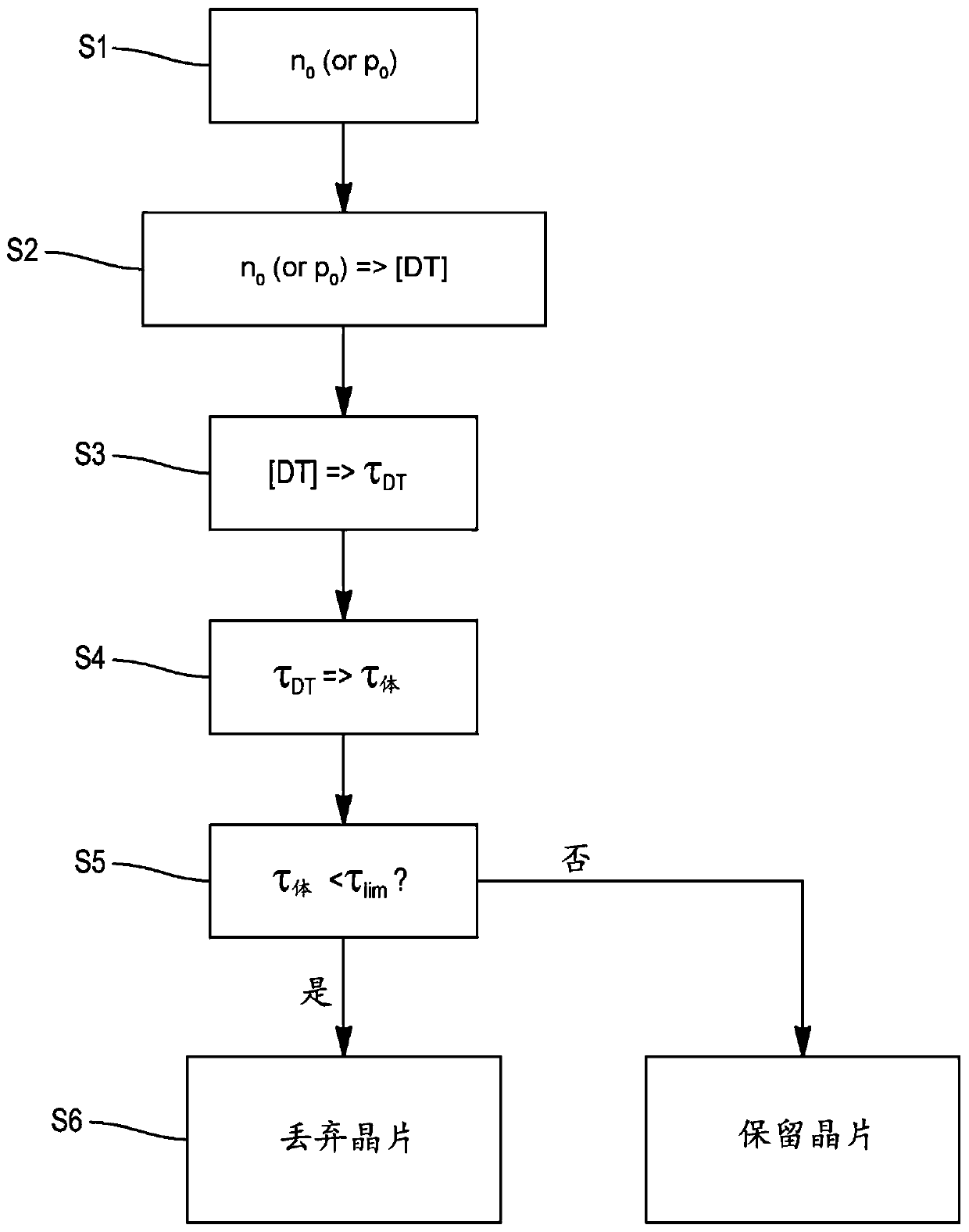

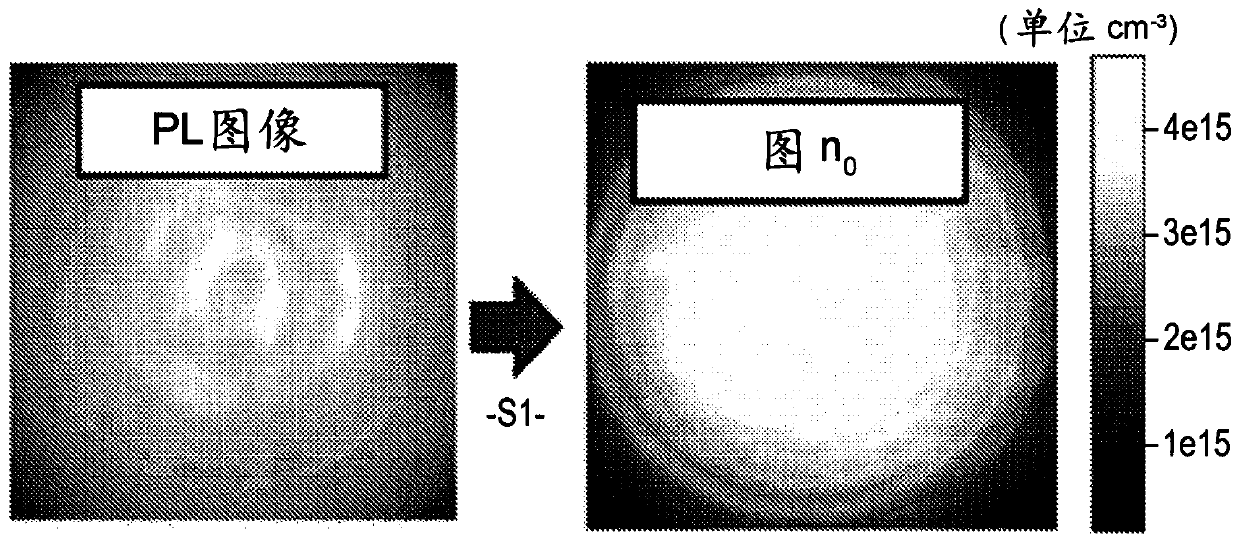

[0062] The sorting method described below exploits these two effects to determine the thermal donor concentration from the majority free charge carrier concentration, and to determine the thermal donor-limited lifetime from the thermal donor concentration, respectively.

[0063] These methods are performed while the wafer is preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com