Capsule tearing device and aerostat using the device

A technology of aerostats and capsules, applied in the field of aerostats, can solve problems such as high power requirements, slow emergency response, incomplete implementation of capsule tearing, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

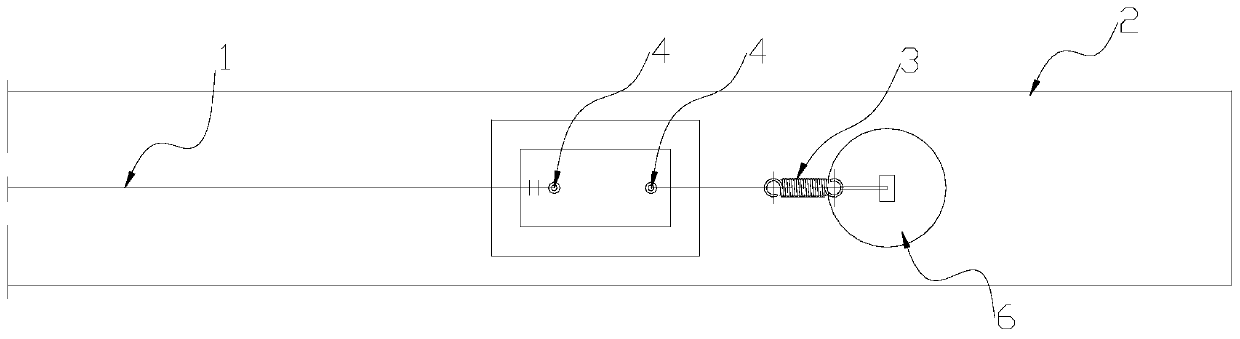

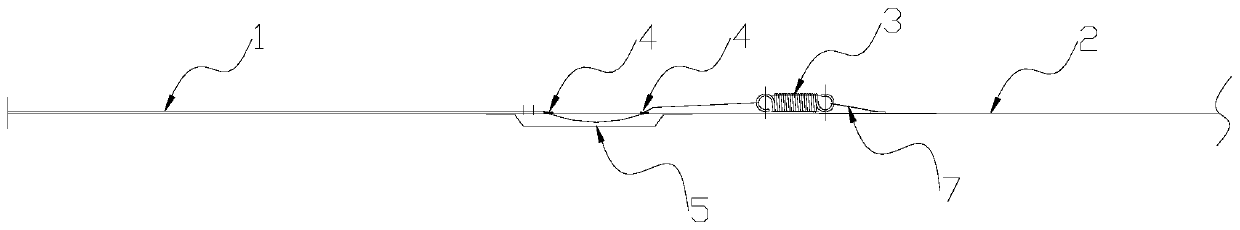

[0024] Such as Figure 1~5 As shown, the capsule 2 of the aerostat of this embodiment includes a helium chamber 11 and an air chamber 12, and the capsule tearing device of this embodiment is arranged on the helium chamber 11 of the aerostat.

[0025] The capsule tearing device of this embodiment includes a superalloy wire 1 arranged on the capsule 2, a tensile member 3, an external power supply and a pull ring 6; the superalloy wire 1 is arranged outside the capsule 2, and the high temperature The two ends of the alloy wire 1 are respectively connected to the ends of the tensile member 3, the tensile member 3 is in a stretched state and the superalloy wire 1 is pasted on the outside of the capsule body 2, and the pull ring 6 is fixed on the On the capsule body 2, a pull rope 7 is connected to the pull ring 6, the head end of the tensile member 3 is connected to the pull rope 7, and the superalloy wire 1 is connected to an external power supply. After the external power supply ...

Embodiment 2

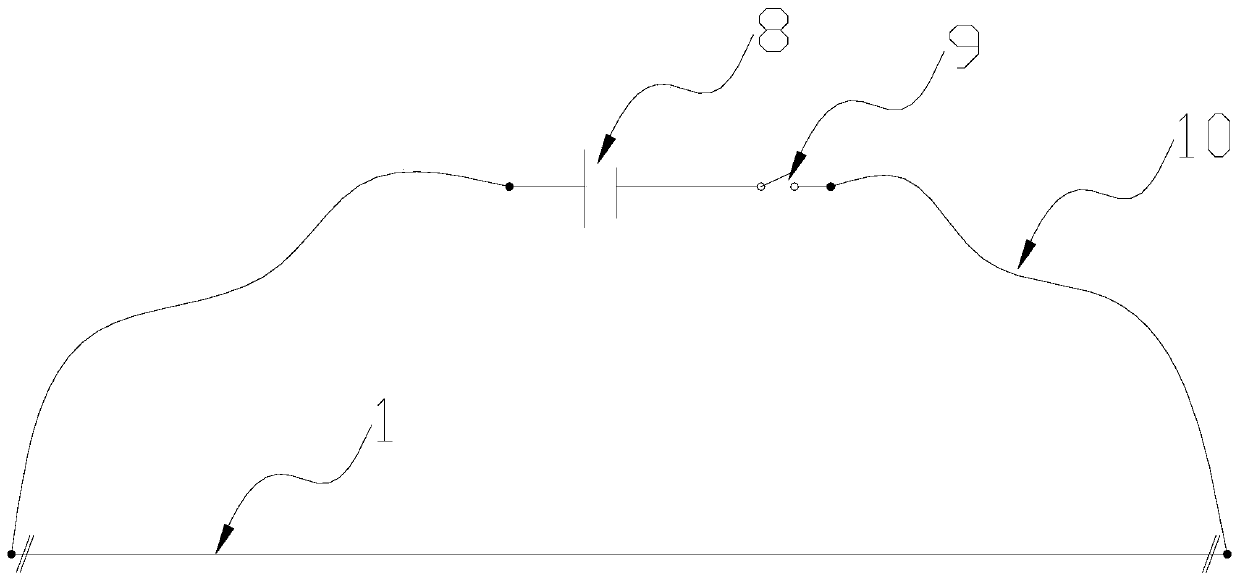

[0033] Such as Figure 6 As shown, the capsule tearing device of this embodiment is arranged on the air chamber 12 of the aerostat. After the switch 9 is closed, the capsule body 2 is burnt into a linear tear band, and the braid of the capsule body 2 is quickly cut to release the air in the capsule body 2 .

[0034] Other implementations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com