Building construction lifting platform capable of feeding materials circularly

A technology for building construction and lifting platforms, which is applied in construction, building construction, lifting devices, etc., can solve the problems of high platform prices and increase construction costs, and achieve the effects of good practicability, ingenious structure and less material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

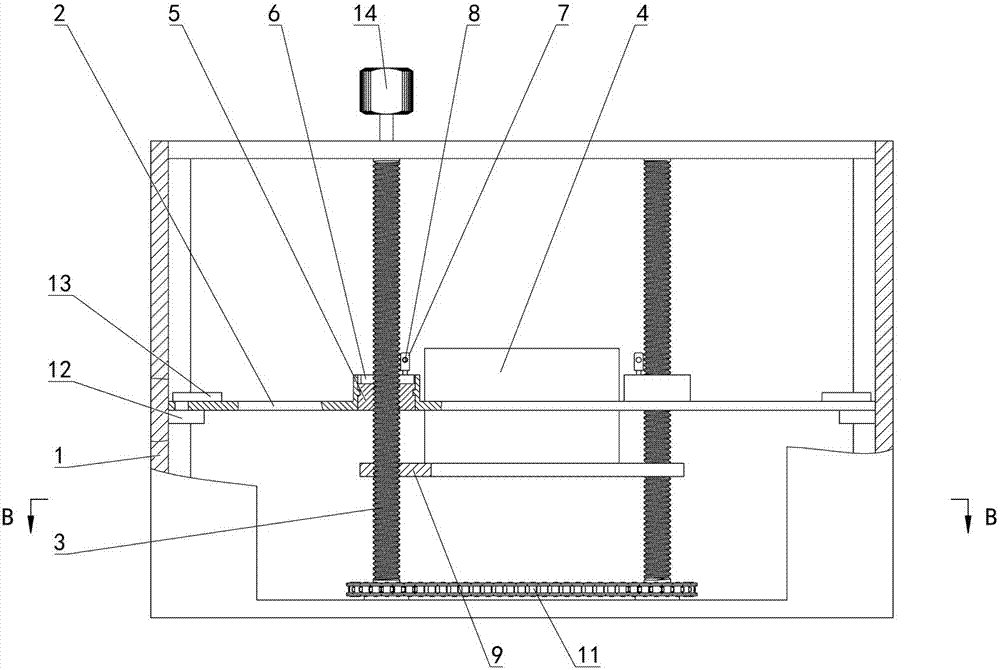

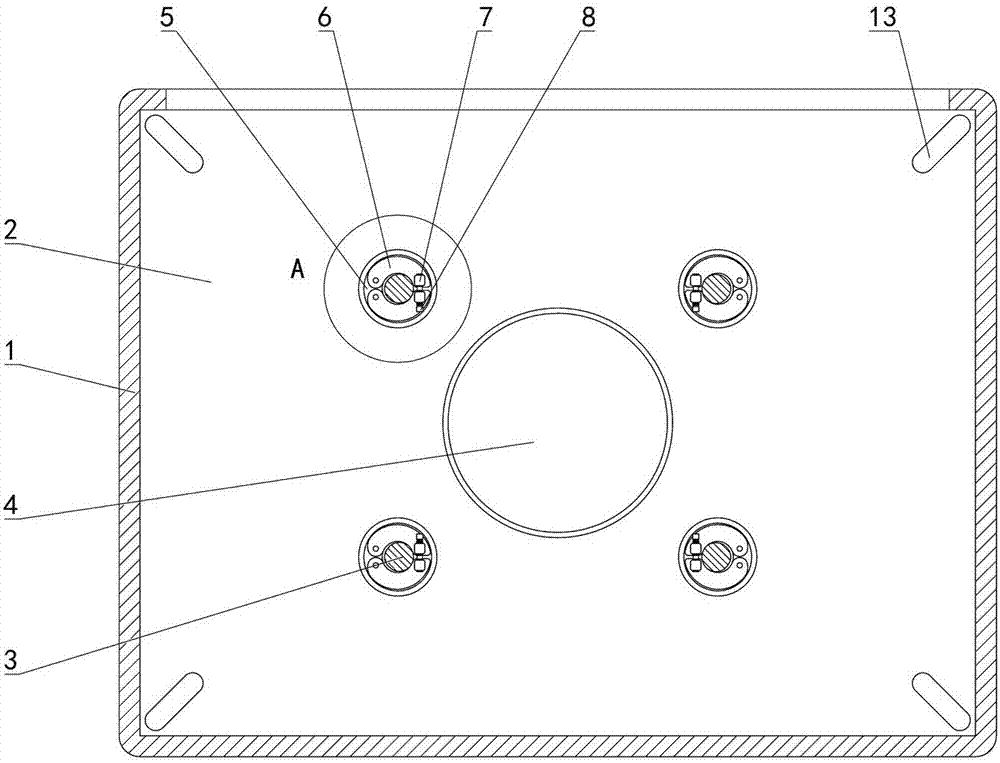

[0016] Depend on Figure 1 to Figure 5 Given, the present invention comprises a safety frame 1, a horizontally arranged lifting platform 2, a plurality of vertically arranged lead screws 3 and a vertically arranged material barrel 4; the two ends of the lead screw 3 are respectively installed on the safety frame 1, forming The structure in which the lead screw 3 rotates on the safety frame 1;

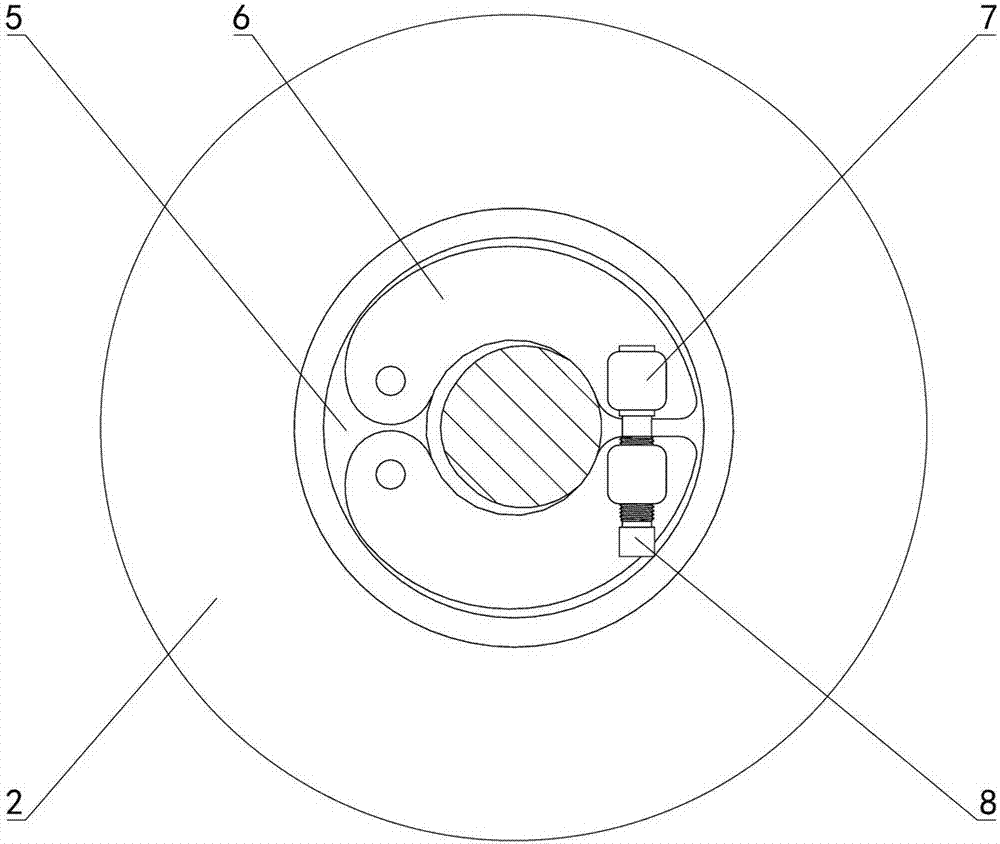

[0017] The horizontally rotatable connection block 5 arranged coaxially with the lead screw 3 is housed on the described lifting table 2, the lead screw 3 vertically penetrates the connection block 5 and is threadedly connected with the connection block 5 through the lead screw, and the connection block 5 is installed There are two friction half rings 6 that can rotate horizontally, and the two friction half rings 6 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com