Automatic cut wire crimping machine with alarm device

A technology of an alarm device and a crimping machine, which is applied in the direction of alarms, equipment for connecting/terminating cables, instruments, etc., and can solve the problems of no alarm function, knotting, bending, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

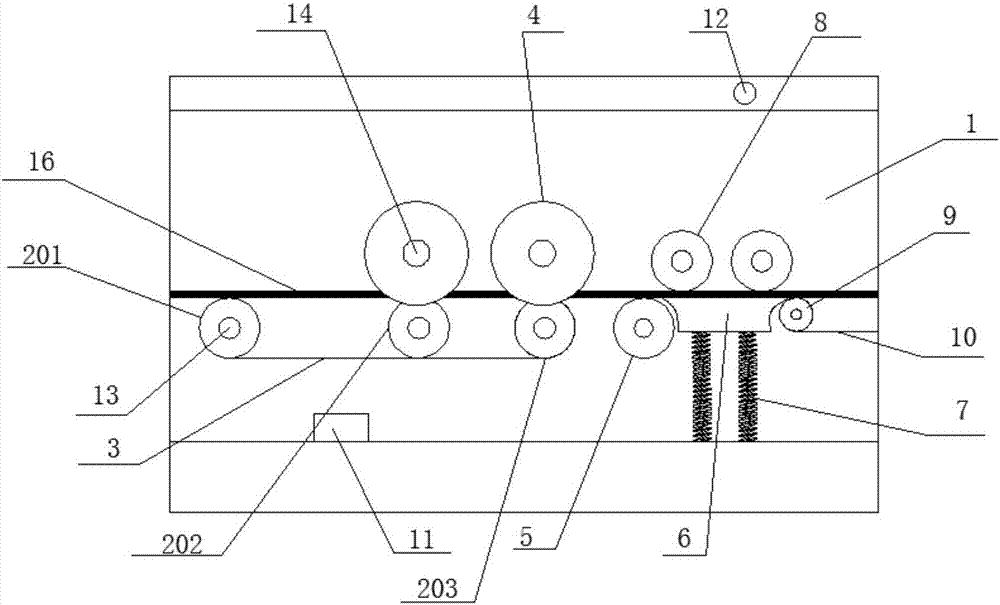

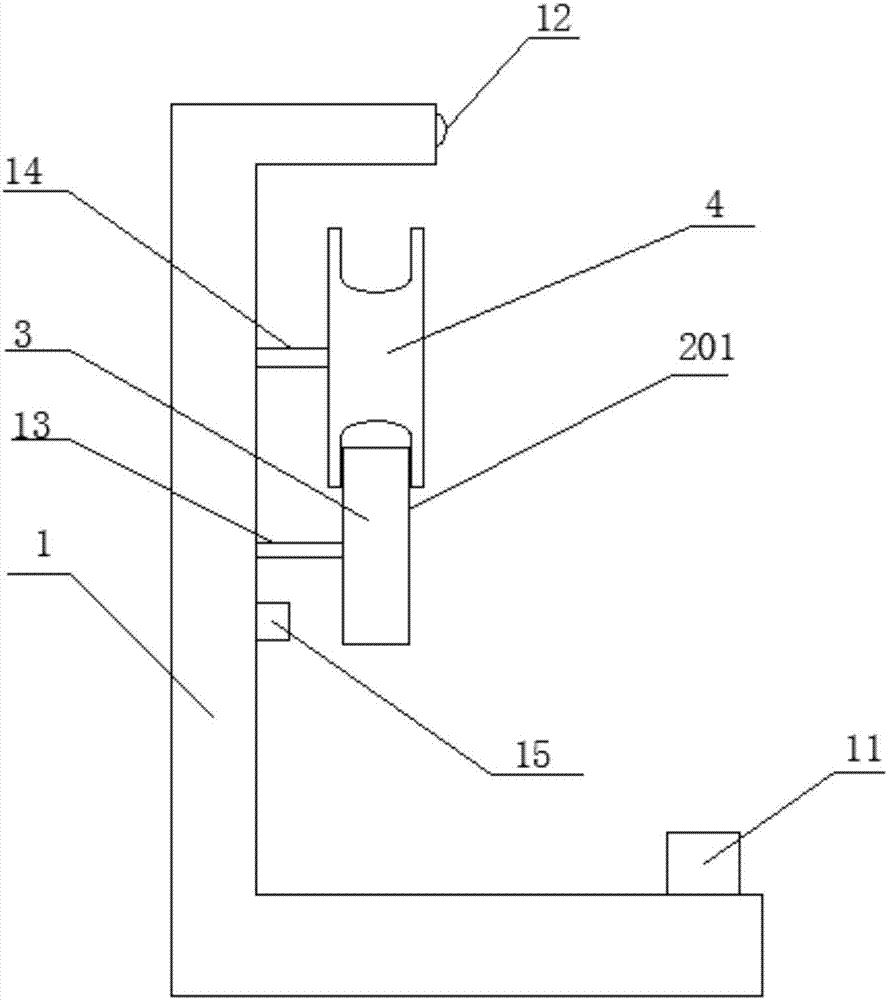

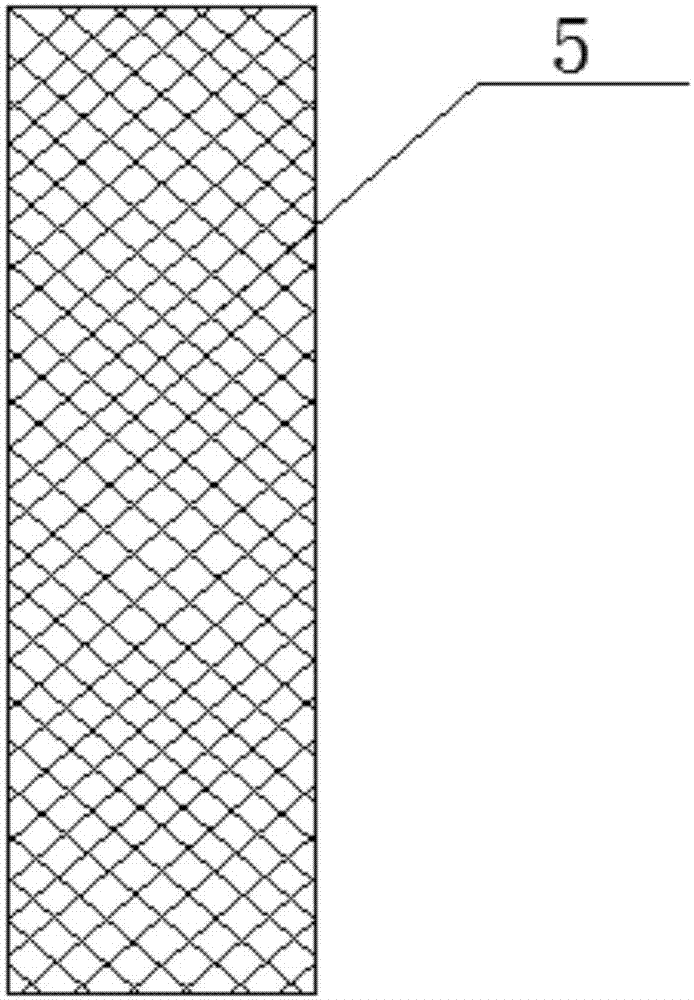

[0017] figure 1 , figure 2 , image 3 with Figure 4 The specific embodiment of the present invention is shown: a fully automatic thread cutting and crimping machine with an alarm device, comprising a crimping machine body, the crimping machine body is provided with a base 1, and a transmission wheel is provided on the base 1 One 201, transmission wheel two 202, transmission wheel three 203, transmission wheel four 5 and transport wheel 9, said transmission wheel one 201, transmission wheel two 202 and transmission wheel three 203 are connected by conveyor belt one, said transmission wheel two 202 A pressure wheel 4 is provided above the transmission wheel three 203, and the transmission wheel four 5 is provided at the output end of the transmission wheel three 203, and the output end of the transmission wheel four 5 is provided with a sizing table 6, the sizing table 6 is connected to the base 1, a sizing wheel 7 is arranged above the sizing table 6, and the transport wheel 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com