Assembly line type clothes control storage device

An assembly-line storage device technology, applied in wardrobes, furniture accessories, home appliances, etc., can solve the problems of limited function and low efficiency, and achieve the effect of comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

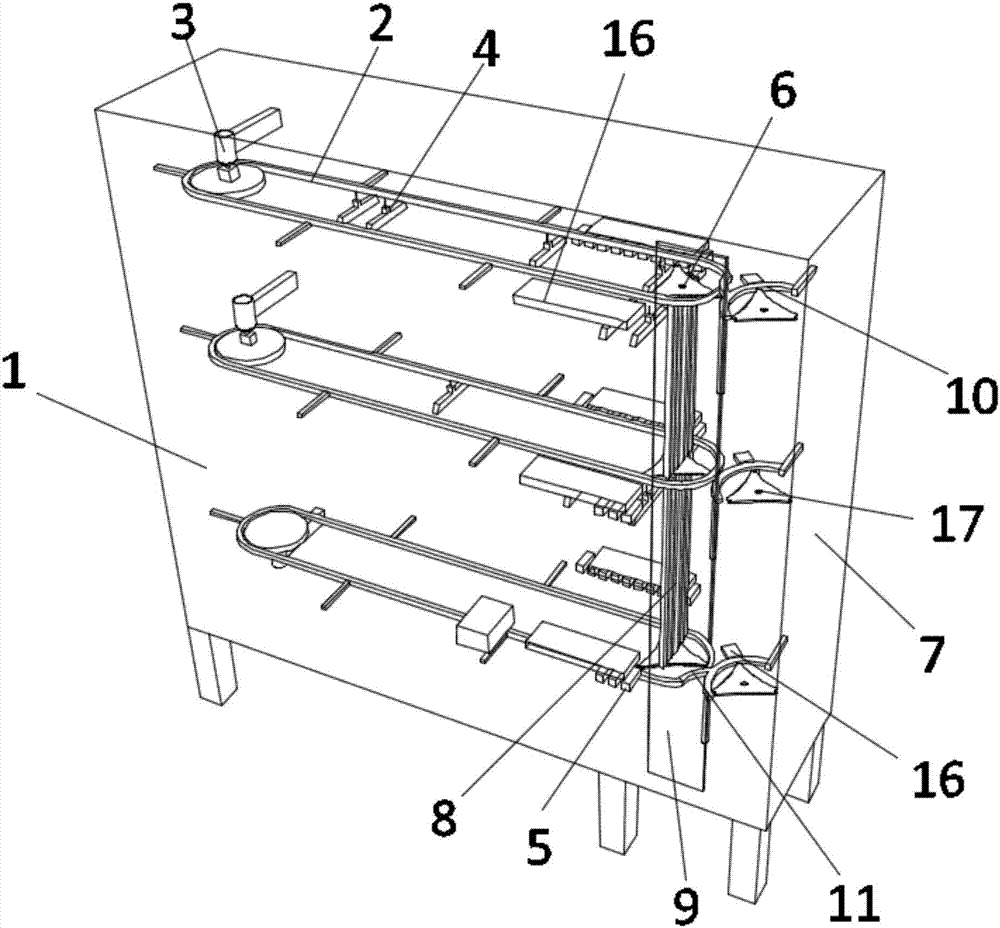

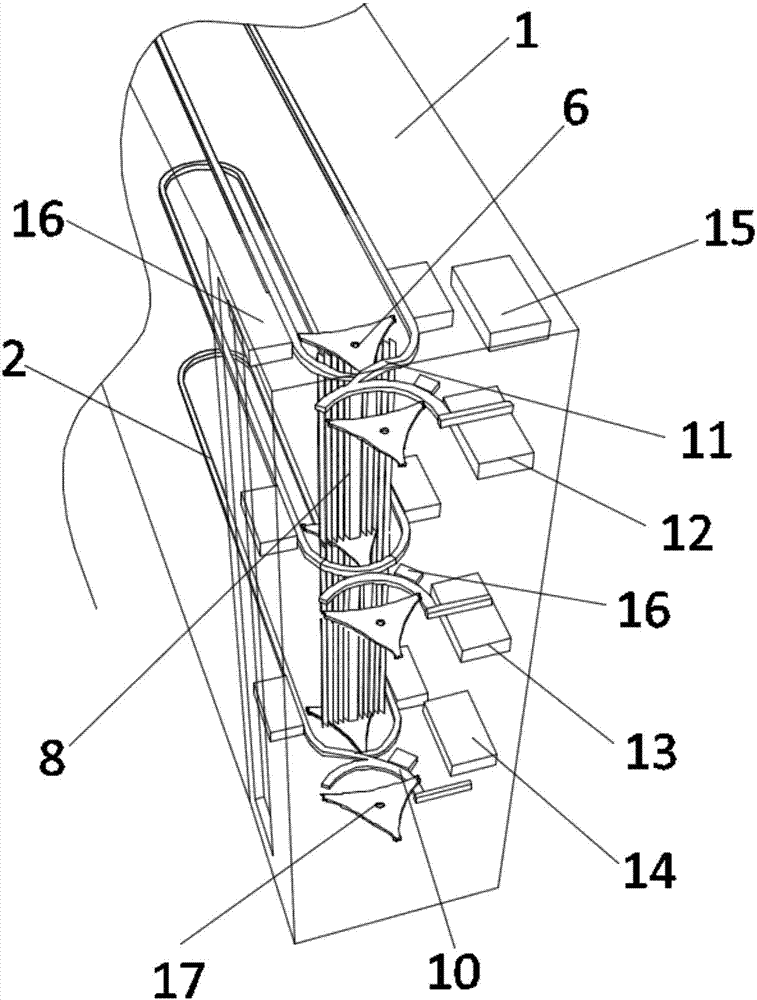

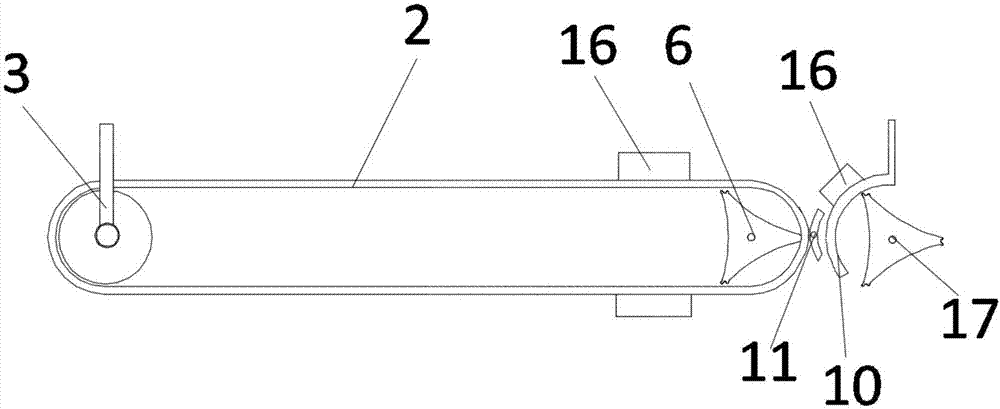

[0023] see figure 1 , figure 2 with Figure 4 , the present invention provides a technical solution: a storage device for controlling clothes in an assembly line, including a cabinet body 1, and an open-loop clothes flow line 2 is arranged in the cabinet body 1, which is suitable for accessing less clothes, and the clothes flow line 2 The open-loop structure of the open-loop structure uses less raw materials, which saves the production cost. The minimum storage unit 4 carrying the identification information carrier is arranged on the clothing flow line 2. The minimum storage unit 4 can be a hanger, a box or a grid. The minimum storage unit 4 The form of the identification information carrier can be a two-dimensional code, a bar code or a radio frequency RFID. One end of the clothing flow line 2 is provided with a motor drive assembly 3, and the motor drive assembly 3 is drivingly connected with the clothes flow line 2. The motor drive assembly 3 drives the clothes flow line ...

Embodiment 2

[0025] see Figure 1-2 , the present invention provides a technical solution: a storage device for controlling clothes in an assembly line, including a cabinet body 1, and an upper, middle and lower three-layer clothing flow line 2 is arranged in the height direction of the cabinet body 1, and the clothes flow line 2 is There is a minimum storage unit 4 carrying an identification information carrier, the minimum storage unit 4 on the upper clothing flow line 2 can be a hanger, which is convenient for hanging and taking the coat, and the minimum storage unit 4 on the middle layer clothing flow line 2 can be a hanger or a box, which is convenient for hanging Take and store pants and other lower garments. The smallest storage unit 4 on the lower clothing flow line 2 can be a grid or a box, which is convenient for storing small items such as shoes or socks. By separately fetching the clothes on the three-layer clothing flow line 2, the clothes can be stored. Matching, one end of t...

Embodiment 3

[0027] see Figure 1-3 with Figure 5, the present invention provides a technical solution: a storage device for controlling clothes in an assembly line, including a cabinet body 1, a clothes flow line 2 is provided inside the cabinet body 1, the shape of the clothes flow line 2 is a closed loop form, and the clothes flow line 2 is provided with The minimum storage unit 4 carrying the identification information carrier, the minimum storage unit 4 can be a hanger, box or grid, the form of the identification information carrier on the minimum storage unit 4 can be a two-dimensional code, bar code or radio frequency RFID, one end of the clothing flow line 2 A motor drive assembly 3 is provided, and the motor drive assembly 3 is drivingly connected to the clothes flow line 2. The motor drive assembly 3 drives the clothes flow line 2 to rotate, so that the smallest storage unit 4 moves on the clothes flow line 2. The motor drive assembly 3 is connected to the cabinet through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com