Efficient raw material mixing device for feed production

A mixing device and raw material technology, which is applied in the field of forest insect control, can solve the problems of unsatisfactory mixing effect of raw materials, affecting the mixing effect of mixing, and easy adhesion of raw materials, etc., to achieve the effect of improving mixing effect, promoting fusion, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

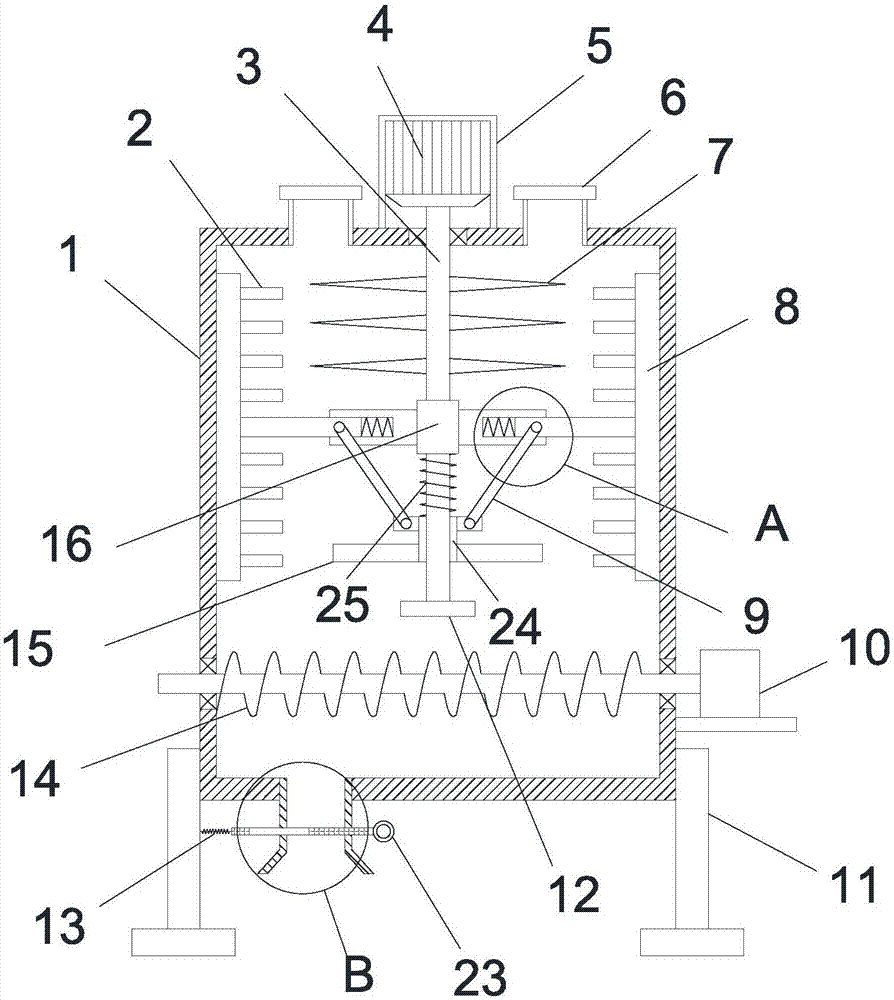

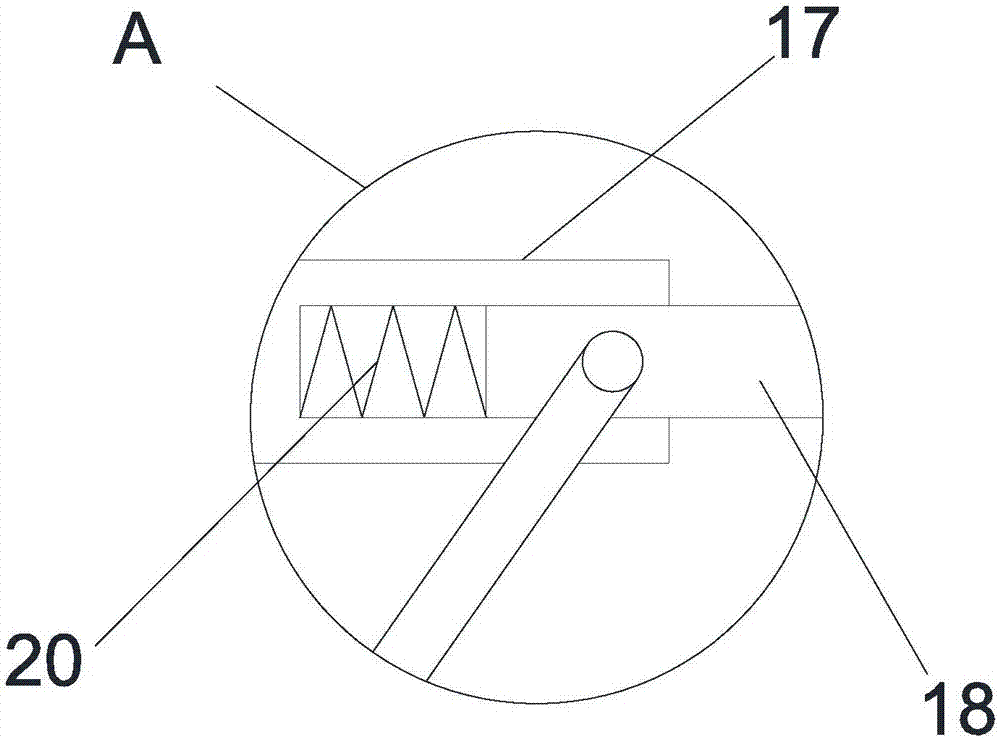

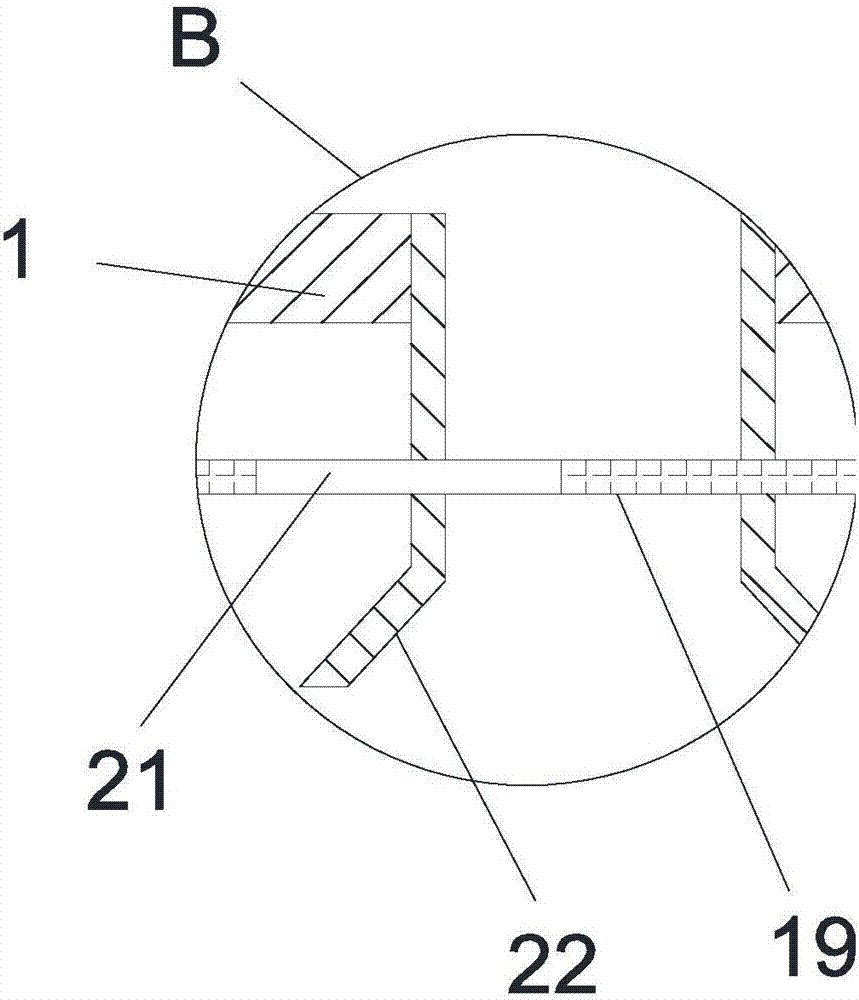

[0019] see Figure 1-3 , a high-efficiency mixing device for raw materials for feed production, comprising a mixing chamber 1, two feed pipes 6 are provided on the top of the mixing chamber 1, and support legs 11 are welded and fixed at the bottom of the mixing chamber 1; Discharge pipe 22, the horizontal sliding type on the discharge pipe 22 is provided with blanking baffle 19, vertically on the blanking baffle 19 is provided with a discharge through hole 21, and the right end of blanking baffle 19 is provided with pull ring 23, and the blanking Back-moving spring 13 is arranged between baffle plate 19 and support leg 11, and the left end of back-moving spring 13 is fixed on the supporting leg 11, and the right end of back-moving spring 13 is fixed on blanking baffle plate 19 left end; The top of described mixing chamber 1 is provided with motor frame 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com