Spring coiling machine and spring coiling process

A spring coiling machine and coiling spring technology, which is applied in the field of spring coiling machine and spring rolling process, can solve the problems of different bending arcs of springs, insufficient roundness of spring coils, and different spring force, so as to meet production needs and avoid pressure uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

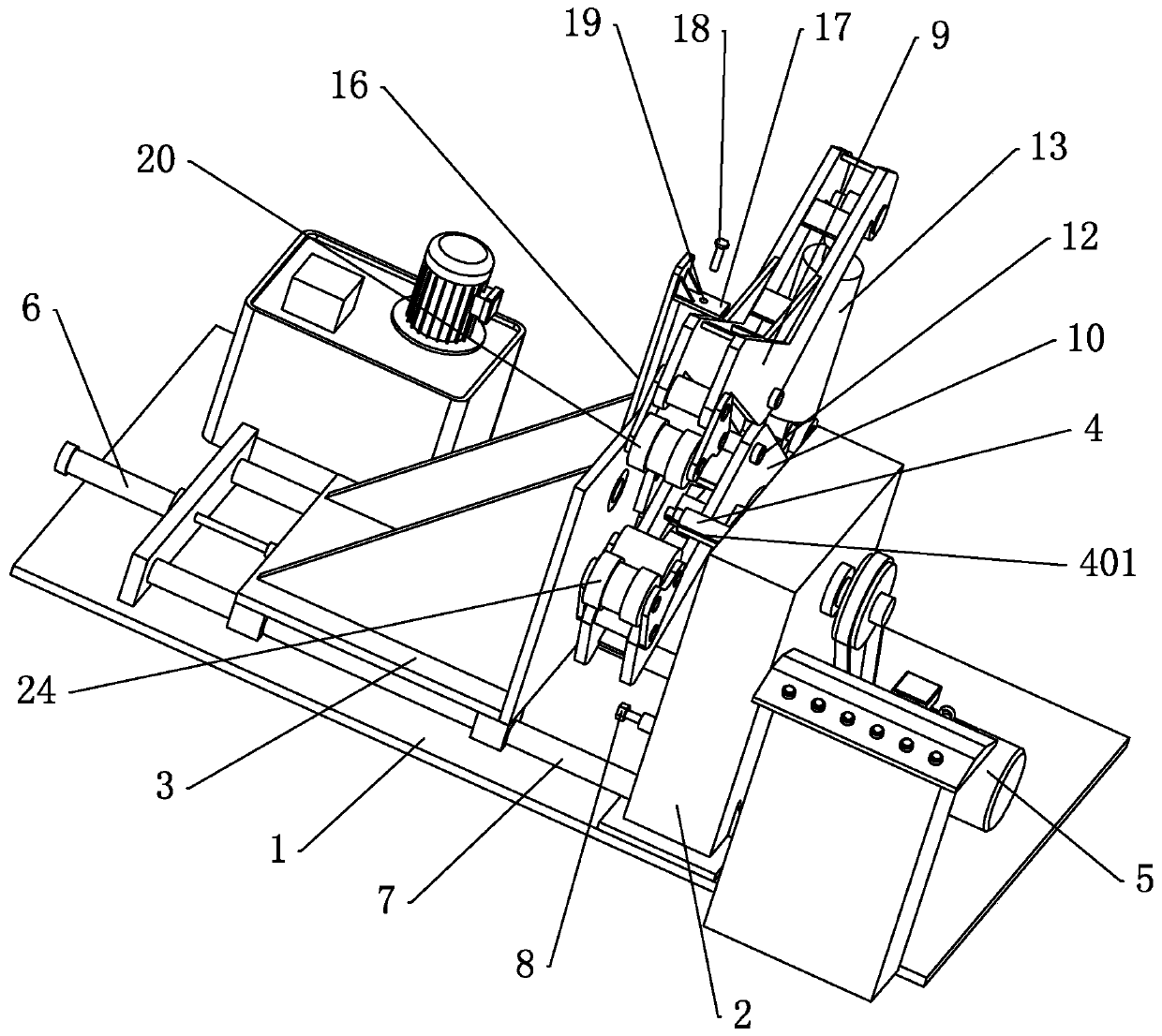

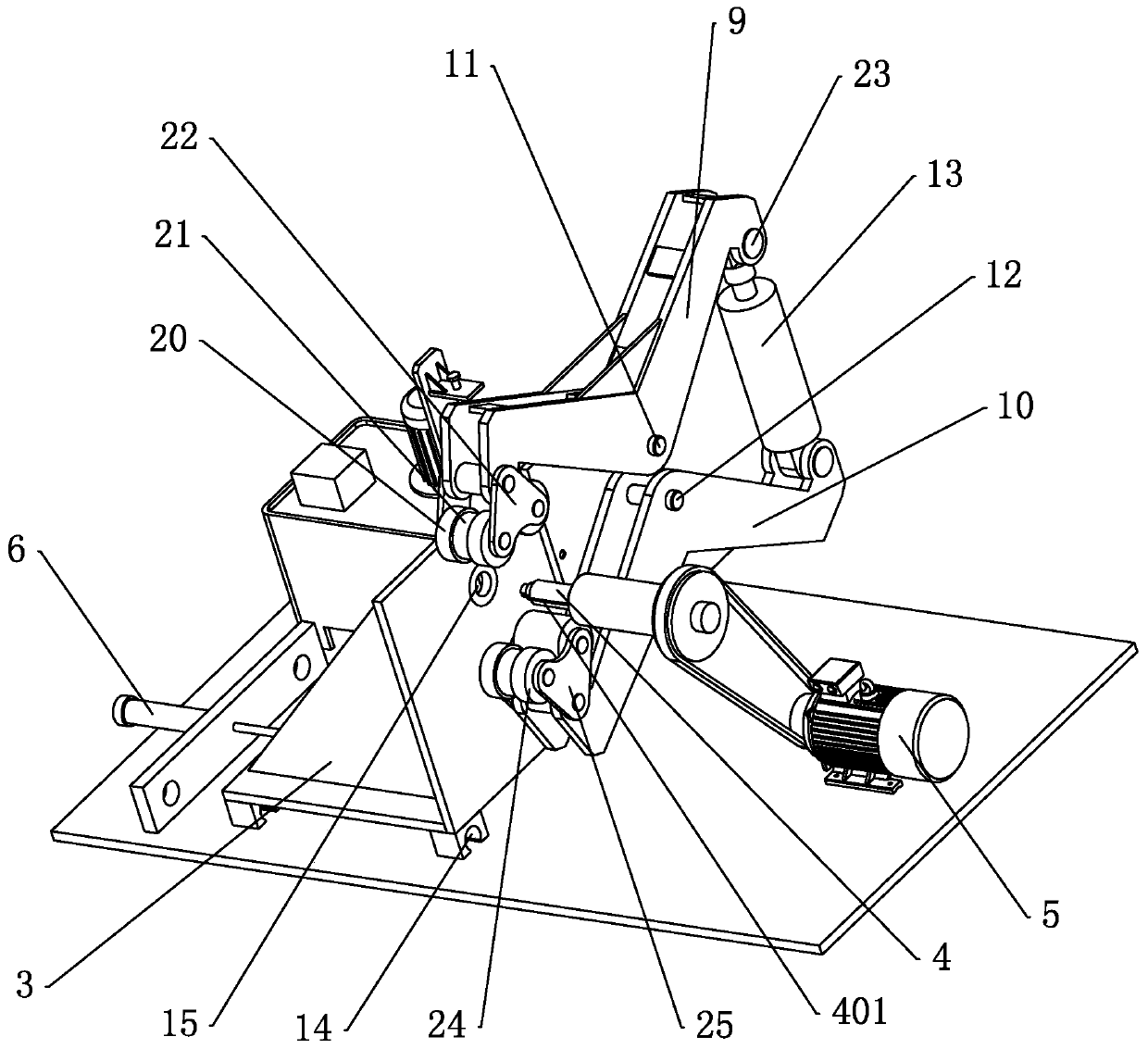

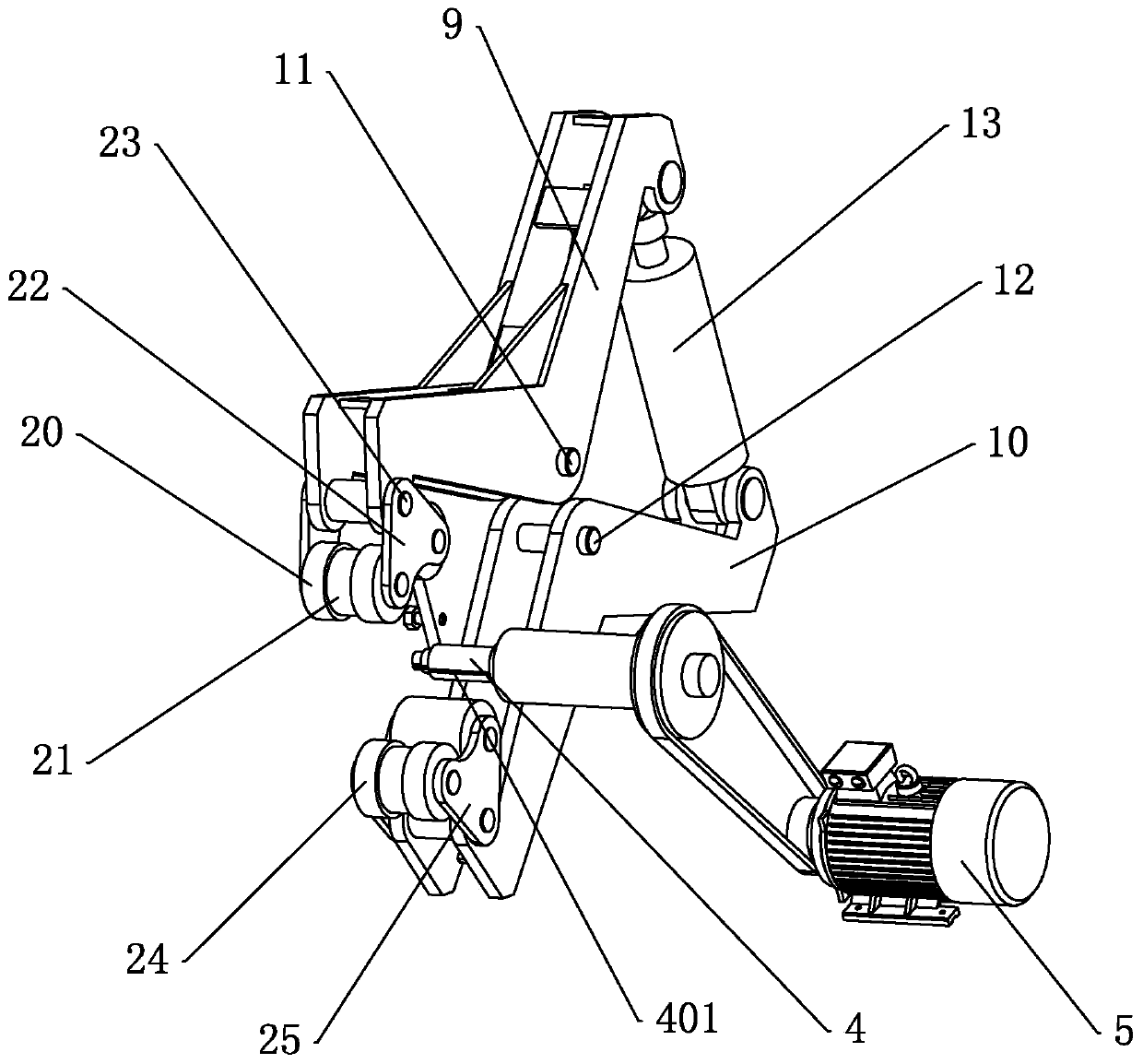

[0034] Embodiment 1: a kind of coil spring machine, as figure 1 and figure 2 As shown, it includes a horizontal base 1, the base 1 is provided with a first side frame 2 perpendicular to the surface of the base 1, and the first side frame 2 is provided with a coil spring shaft 4 and a driving motor for driving the coil spring shaft 4 to rotate 5. The coil spring shaft 4 is rotationally connected with the surface of the first side frame 2, the axis of the coil spring shaft 4 is perpendicular to one side surface of the first side frame 2, and the outer peripheral surface of the coil spring shaft 4 is provided with a spring plate snap into the fixed slot 401 together with the gasket, and the slot 401 extends upward along the axis of the coil spring shaft 4;

[0035] The surface of the base 1 is slidingly connected with the second side frame 3, the first side frame 2 is opposite to the second side frame 3 left and right, the base 1 is provided with a driving part 6, and the drivi...

Embodiment 2

[0049] Embodiment 2: A kind of spring rolling process, use embodiment 1 to carry out the coil spring production, the steps of this process are as follows: one end of the strip-shaped spring piece and one end of the gasket are snapped onto the coil spring shaft 4 together, and the length of the gasket is , the width is the same as the length and width of the spring sheet, the gasket is attached to the outer surface of the spring sheet, and the coil spring shaft 4 rotates to drive the spring sheet and the gasket to be wound together; after the coiling of the spring is completed, the gasket is manually Remove from spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com