The construction method of the bottom working layer of the annular heating furnace

一种环形加热炉、施工方法的技术,应用在热处理炉、照明和加热设备、炉等方向,能够解决增加检修次数、扩大成本、加热不均匀等问题,达到保证轧制质量、延长使用寿命、减少检修次数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

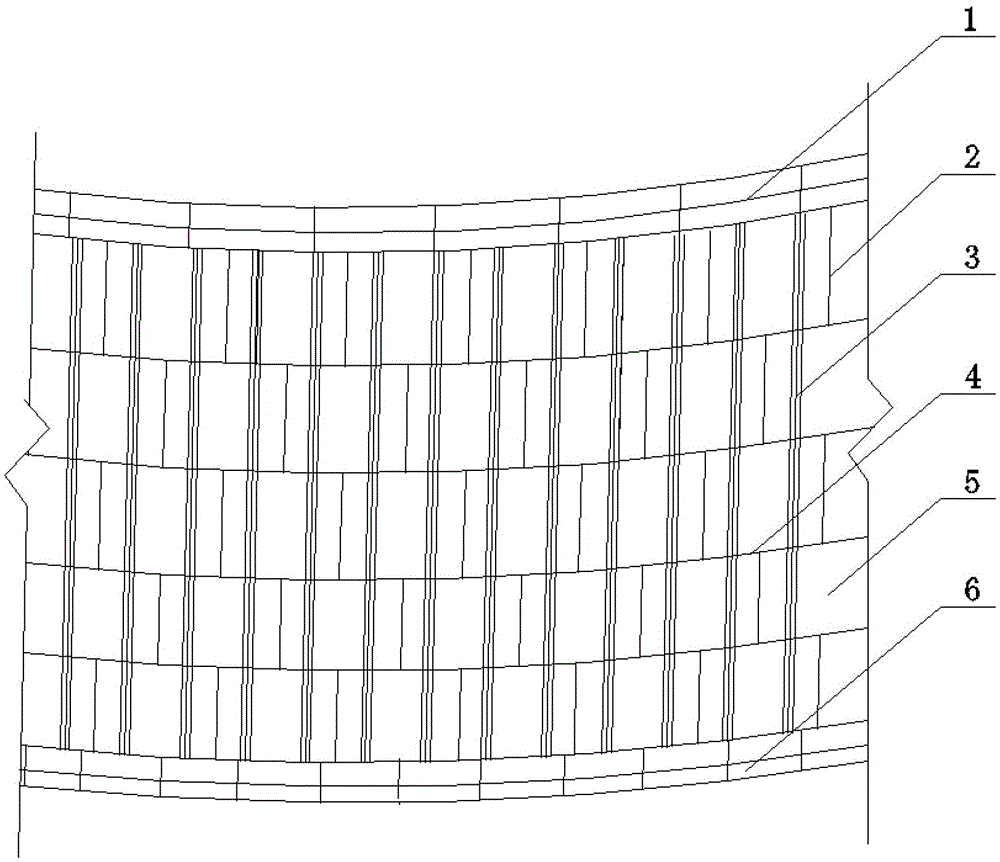

[0018] A construction method for the bottom working layer of an annular heating furnace, the construction method steps are:

[0019] (1) Base line construction: Hang and measure the center line of the incoming and outgoing materials outside the annular heating furnace on the platform outside the furnace. The center line of the incoming and outgoing materials outside the heating furnace is measured on the bottom layer of the annular heating furnace, and used as the reference line of the working layer on the bottom layer of the annular heating furnace;

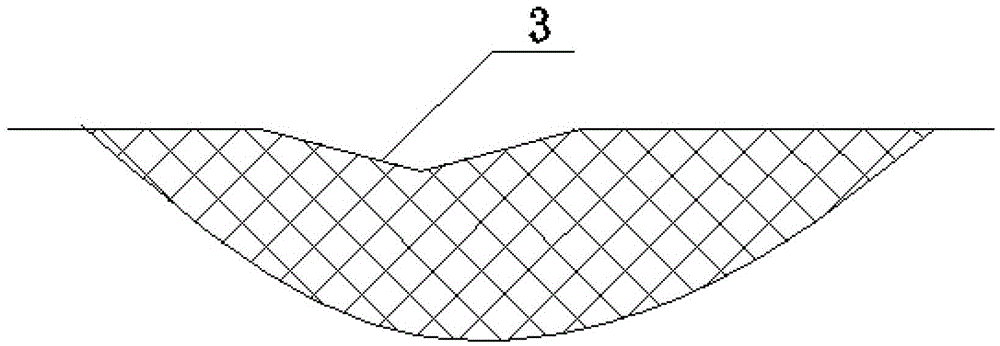

[0020] (2) Support the strip groove mold; install the strip groove mold at radial intervals on the pouring block surface of the working layer between the inner ring beam and the outer ring bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com