Rough rolling device in dual-line hot rolling production line of 105 square casting blanks

A production line and slab technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve problems such as the inability to realize the double-line simultaneous rolling process of 150 square slabs, and achieve increased diameter, improved bearing capacity, and reduced short length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

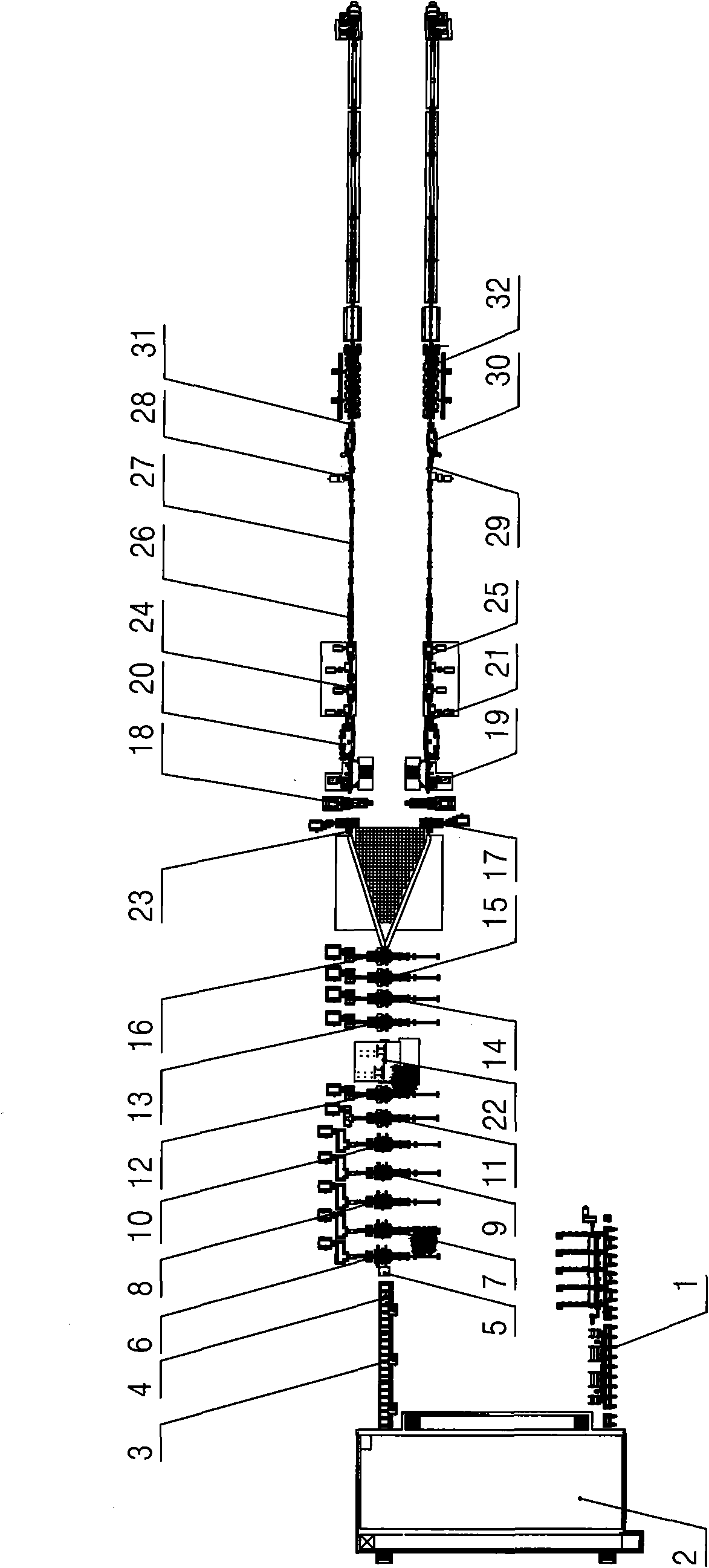

[0010] like figure 1 As shown, the 150 square billet double-strand hot rolling production line includes: feeding stand 1, heating furnace 2, furnace roller table 3, steel separating machine 4, pendulum plus shear 5, and 6 to 12 rough rolling mills from the first to the seventh The rough rolling device that constitutes, and the middle rolling group that is made up of the first to the fourth middle rolling mill 13~16 and two transitional rolling groups that are respectively made up of the fifth middle rolling mill 17, the sixth middle rolling mill 18, two sixth middle rolling mills The back road of rolling mill 18 is also respectively provided with flying shears 19, side loopers 20, snapping shears 21, crank arm shears 22, snapping shears 23, pre-finishing rolling unit 24, vertical loopers 25, Water cooling sections 26 and 27, flying shears 28,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com